Intelligent full-automatic hermetia illucens bioreactor, production line and use method

A technology of bioreactor and black soldier fly, applied in the direction of application, animal feed, animal feed, etc., can solve the problems of equipment cost waste, low automation, lack of standardized control system and control method, etc., to save space and floor area , saving equipment operating costs, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

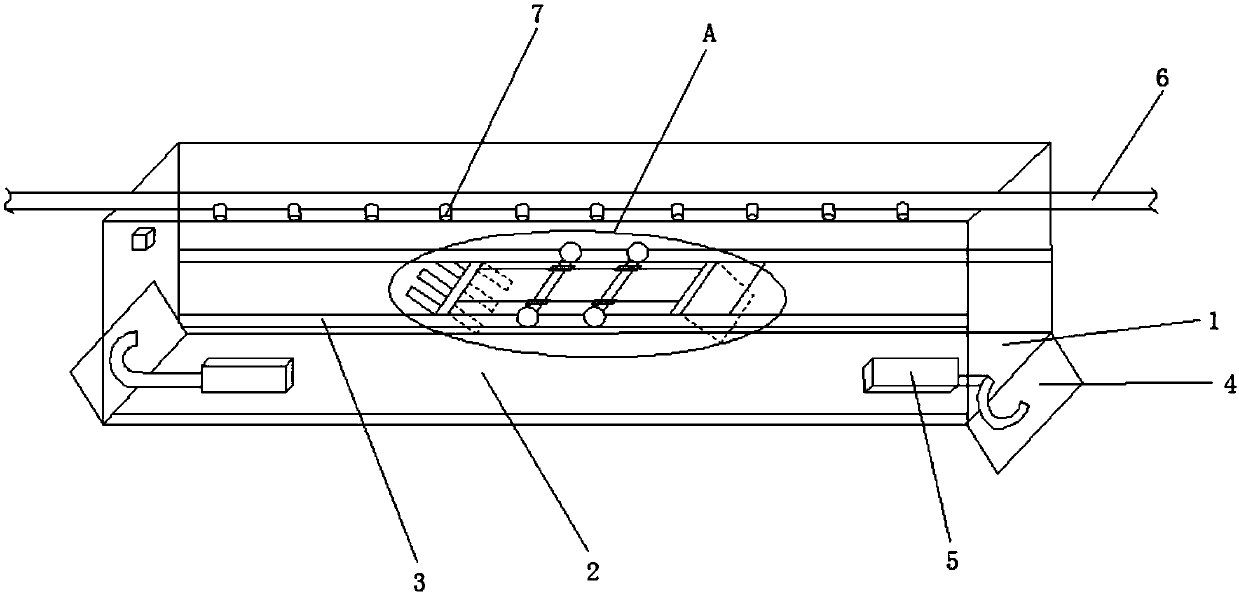

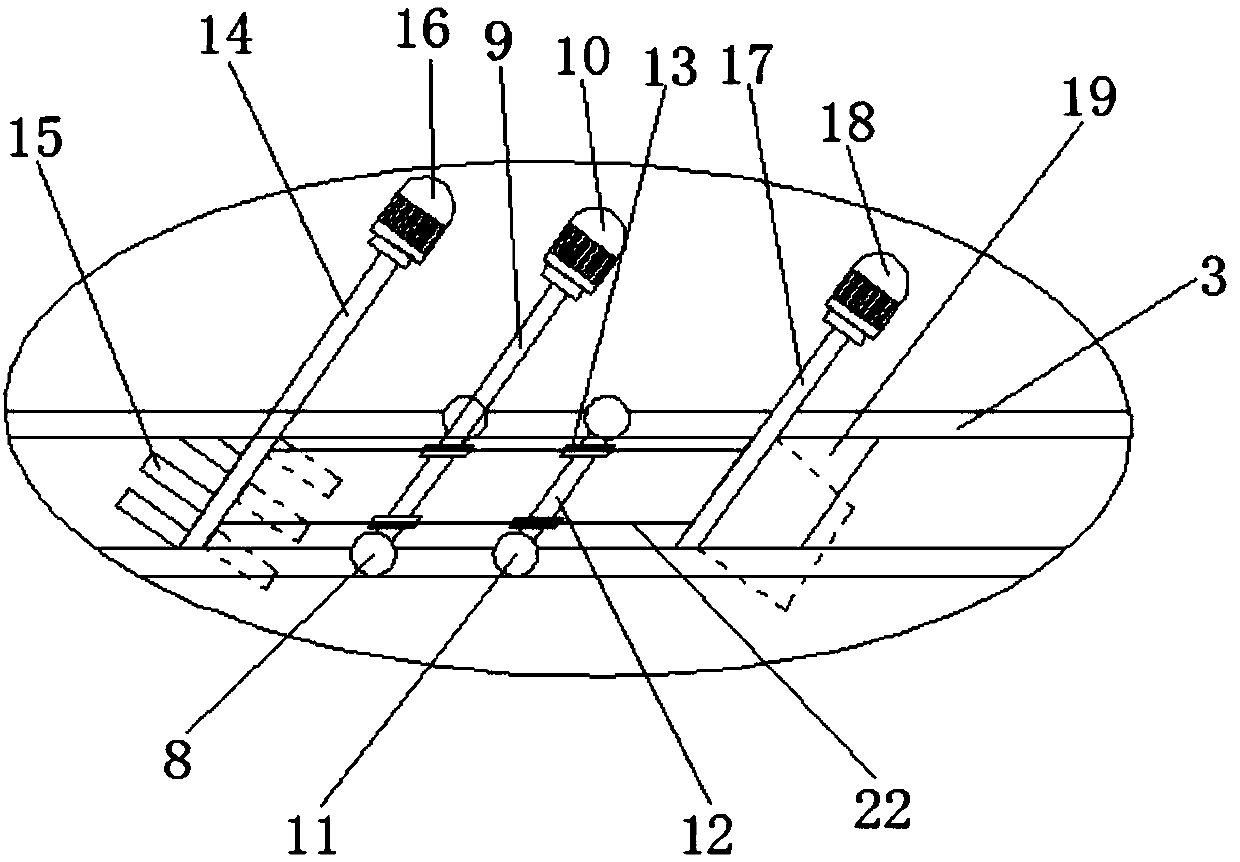

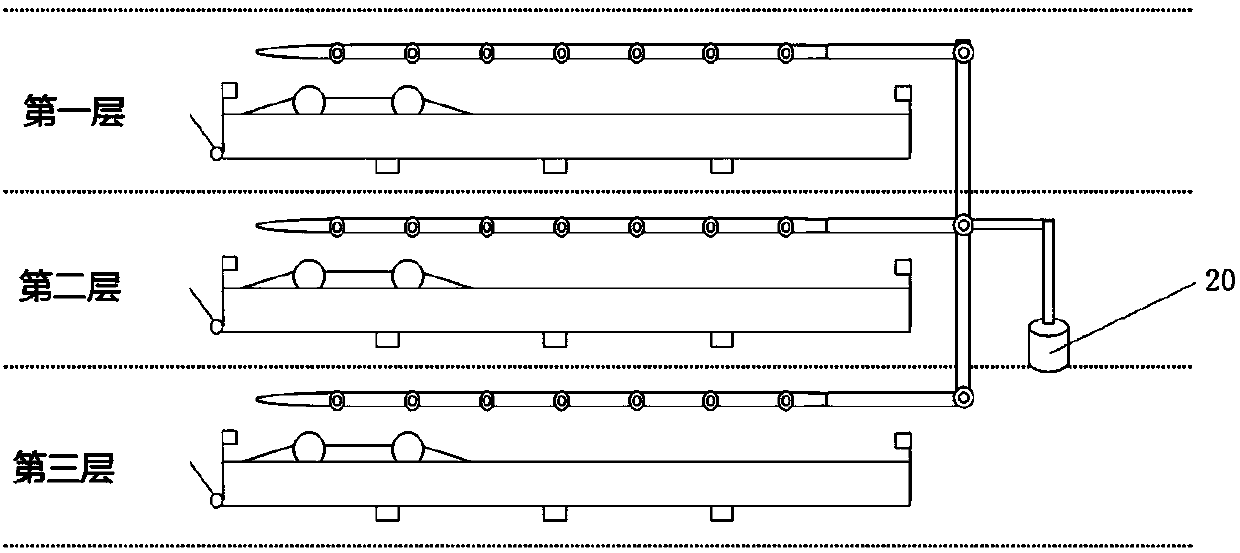

[0038] Such as Figure 1-2 As shown, an intelligent automatic black soldier fly bioreactor, the black soldier fly bioreactor includes a base plate 1 and a cuboid reaction mechanism fixed on the base plate 1, the left and right sides of the reaction mechanism The walls are equipped with automatic discharge doors 4, and two horizontal racks 3 are symmetrically arranged on the front and rear side walls of the reaction mechanism, and the upper parts of the two horizontal racks 3 are provided with first gears that mesh with them. Gears 8, one side of each first gear 8 is also provided with a second gear 11 meshed with the horizontal rack 3, the two first gears 8 are connected through the first rotating shaft 9, and the two The two second gears 11 are connected through the second rotating shaft 12, the first rotating shaft 9 and the second rotating shaft 12 are connected with the frame 22 through the bearing 13, and the first rotating shaft 9 or the second rotating shaft 12 are conn...

Embodiment 2

[0041] Based on Example 1, such as Figure 1-2 As shown, the translation throwing machine includes a fourth rotating shaft 14, a stirring blade 15 fixed on the fourth rotating shaft 14 and a second motor 16 at one end of the fourth rotating shaft 14, and the second rotating shaft 12 is rotatably connected to the On the frame 22, the second motor 16 is electrically connected to the controller.

[0042] It can move back and forth along the horizontal rack 3 and can be turned and thrown evenly during this process, so that the material and black soldier fly larvae can be evenly mixed, and the temperature of the material can be cooled.

Embodiment 3

[0044] Based on Example 1, such as Figure 1-2 As shown, the discharge flap 19 is fixed on the third rotating shaft 17, and the third rotating shaft 17 is rotatably connected to the frame 22. One end of the third rotating shaft 17 is provided with a third motor 18. The third motor 18 is electrically connected with the controller.

[0045] The control panel is operated, and when discharging is required, the controller controls the third motor 18 to start, and the third motor 18 drives the third rotating shaft 17 to rotate the discharge flap 19 to a vertically downward position, so that the material is pushed out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com