Preparation method of pervaporation metal organic framework UiO-66 series gasoline desulfurization film

A metal-organic framework and pervaporation technology, applied in chemical instruments and methods, semi-permeable membrane separation, refining by dialysis, etc., can solve the problems of harsh film forming conditions, harsh membrane synthesis conditions, and affecting separation performance, and achieve high performance Stable, good repeatability and stability, excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

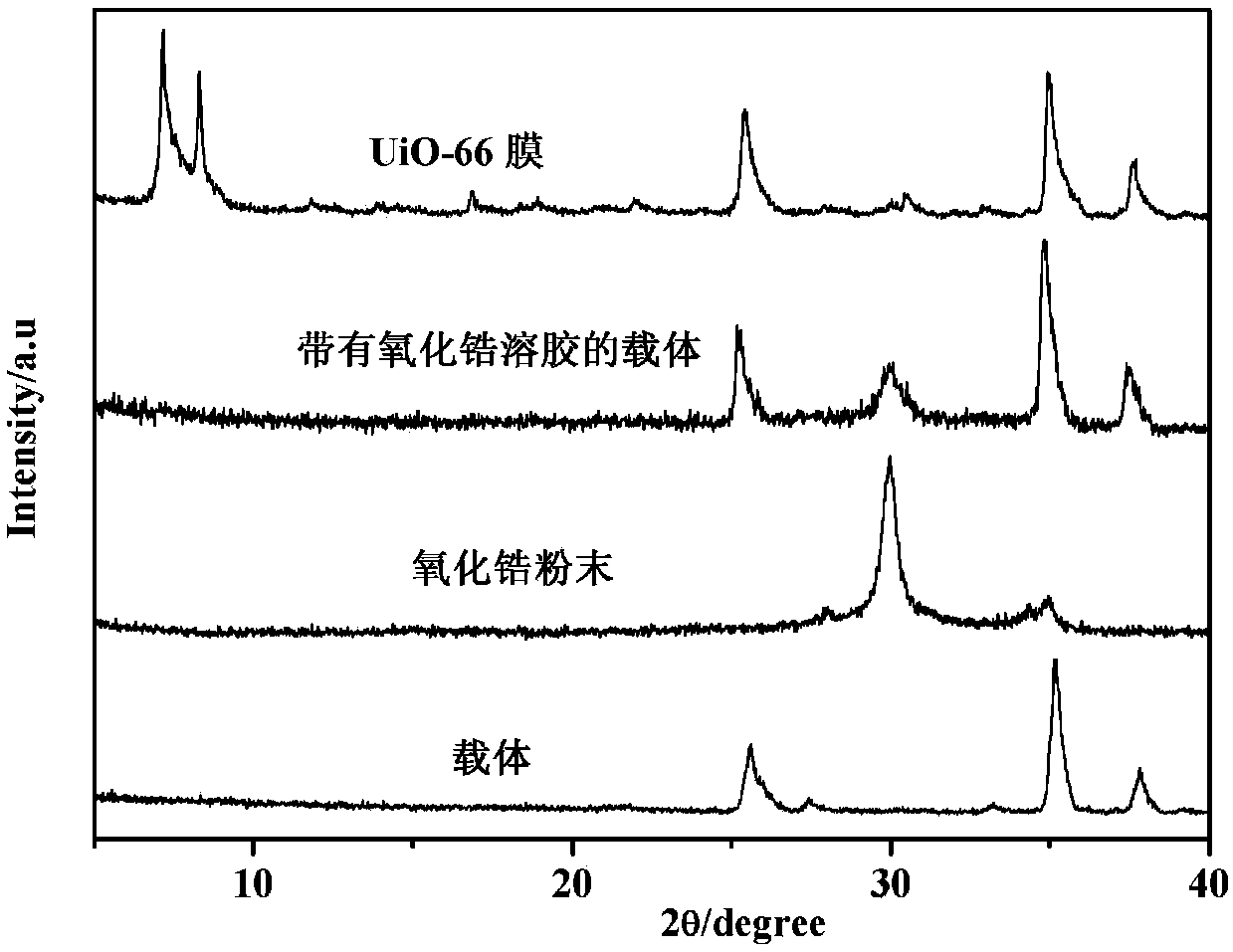

[0017] Preparation of UiO-66 film

[0018] (1) Carrier pretreatment:

[0019] α-Al with a pore size of 0.2 μm 2 o 3 The ceramic tube carrier was vibrated in ultrasonic with acetone and ethanol, then rinsed with deionized water several times, vibrated ultrasonically, and dried at 100°C for later use.

[0020] (2) The inner surface of the carrier is introduced into the zirconia sol layer

[0021] Dissolve 10g of zirconia octahydrate into 50mL of ethanol, stir vigorously at room temperature and add concentrated hydrochloric acid dropwise to adjust the pH to 2.0 to avoid precipitation, stir at room temperature for 12h, and then age for 24h to obtain a colorless and transparent zirconia sol; The rubber-tipped pipette sucks the zirconia sol and adds it to the α-Al 2 o 3 In the ceramic tube carrier, hover and pull for 20s, the thickness of the zirconia sol layer is about 1μm, dry at 60°C for 12h, and then bake in a muffle furnace at 400°C for 4h, with a heating and cooling rate ...

Embodiment 2

[0027] UiO-66-NH 2 Membrane preparation

[0028] (1) Carrier pretreatment:

[0029] Macroporous α-Al with a pore size of 1-3 μm 2 o 3 The ceramic tube carrier was vibrated in ultrasonic with acetone and ethanol, then rinsed with deionized water several times, vibrated ultrasonically, and dried at 100°C for later use.

[0030] (2) Zirconia sol layer is introduced into the inner surface of alumina carrier

[0031]Dissolve 10g of zirconia octahydrate into 50mL of ethanol, stir vigorously at room temperature and add concentrated hydrochloric acid dropwise to pH 2.0 to avoid precipitation, stir at room temperature for 12h, and then age for 24h to obtain a colorless and transparent zirconia sol; The zirconia sol was sucked into the alumina tube with the suction pipe, hovered and pulled for 20s, the thickness of the zirconia sol layer was about 1 μm, dried at 60°C for 12h, and then baked in a muffle furnace at 400°C for 4h, the heating and cooling rates were uniform. 1°C / min.

...

Embodiment 3

[0037] Preparation of mixed ligand membranes

[0038] (1) Carrier pretreatment:

[0039] α-Al with a pore size of 0.2 μm 2 o 3 The ceramic tube carrier was vibrated in ultrasonic with acetone and ethanol, then rinsed with deionized water several times, vibrated ultrasonically, and dried at 100°C for later use.

[0040] (2) The inner surface of the carrier is introduced into the zirconia sol layer

[0041] Dissolve 10g of zirconia octahydrate into 50mL of ethanol, stir vigorously at room temperature and add concentrated hydrochloric acid dropwise to adjust the pH to 2.0 to avoid precipitation, stir at room temperature for 12h, and then age for 24h to obtain a colorless and transparent zirconia sol; The rubber-tipped pipette sucks the zirconia sol and adds it to the α-Al 2 o 3 In the ceramic tube carrier, hover for 20s, dry at 80°C for 10h, and then bake in a muffle furnace at 400°C for 4h, with a heating and cooling rate of 1°C / min.

[0042] (3) Preparation of double-liga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com