Synthesis method of co-catalyst for preparing linear alpha-olefin through ethylene oligomerization and ethylene oligomerization process

A co-catalyst, ethylene oligomerization technology, applied in chemical instruments and methods, physical/chemical process catalysts, compounds containing elements of Group 3/13 of the periodic table, etc., can solve the problem of reducing polyethylene wax content and consumption of co-catalysts problems such as major problems, to achieve the effect of improving utilization efficiency, improving production efficiency, and being easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

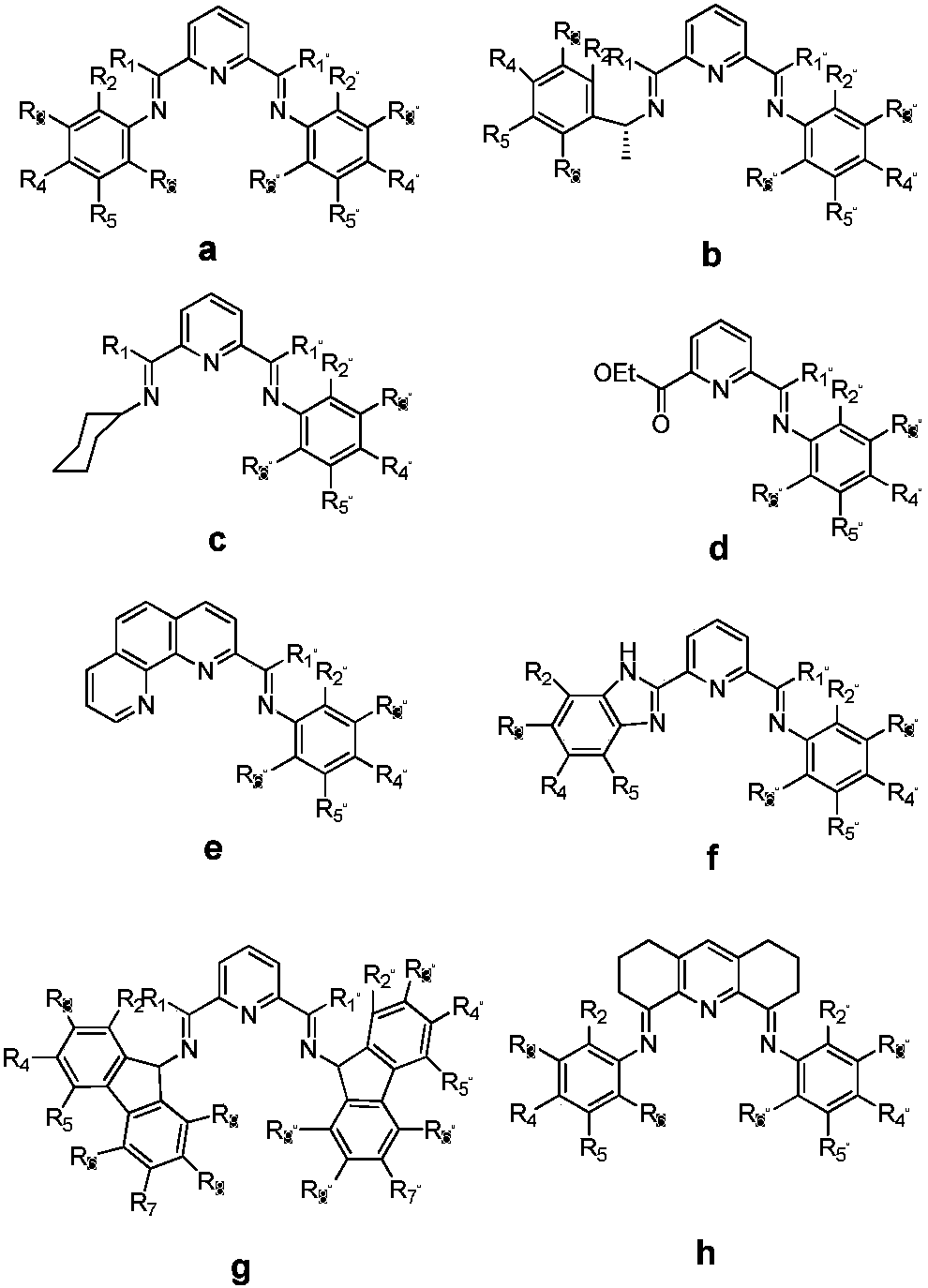

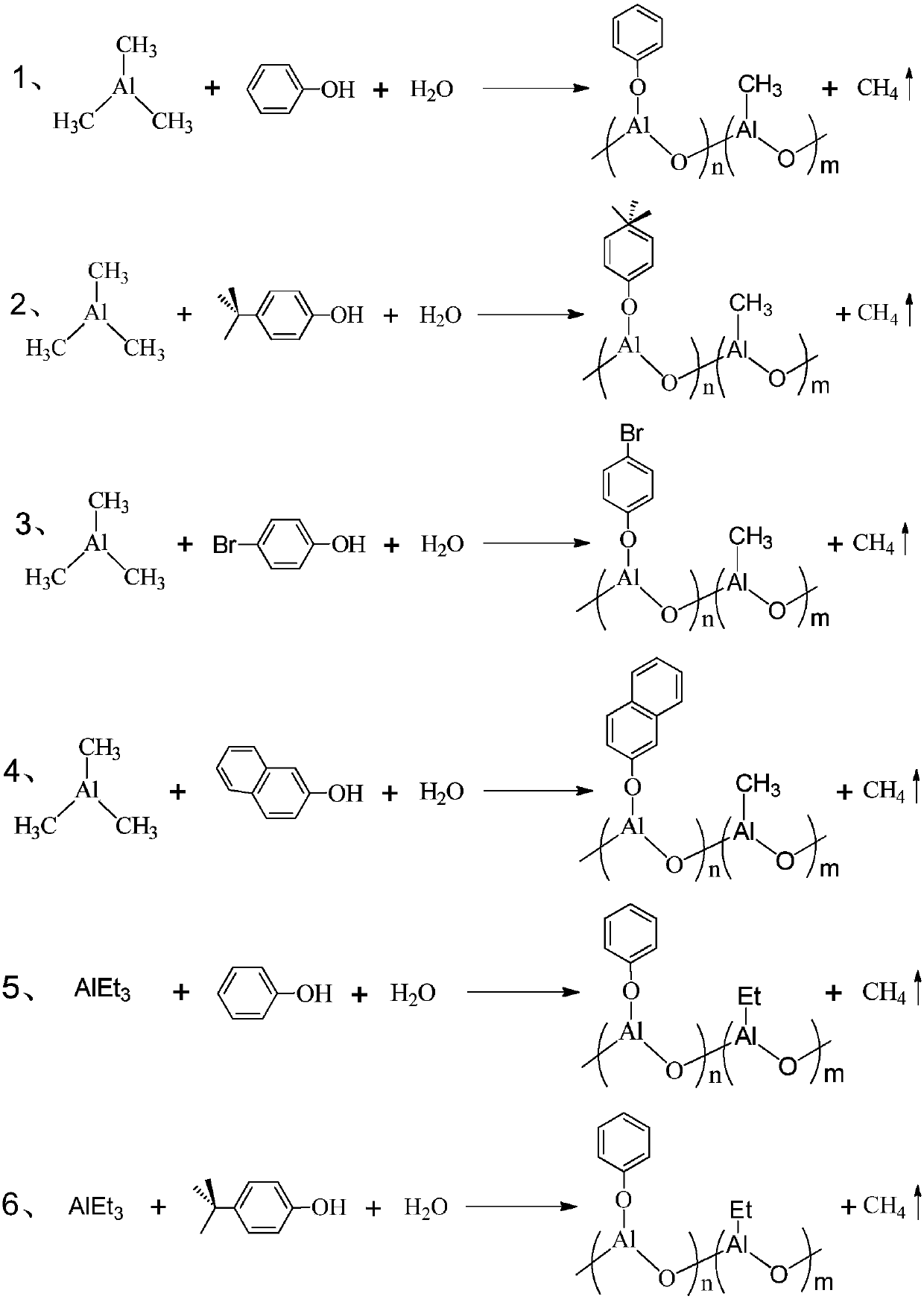

[0036] The synthesis scheme of the co-catalyst is shown in the following formula. Different metal organics, different structure modifiers and water are selected to uniformly mix and react in a certain ratio. The obtained new co-catalyst is used in the ethylene oligomerization reaction. The reaction results are shown in Table 2. .

[0037]

[0038]

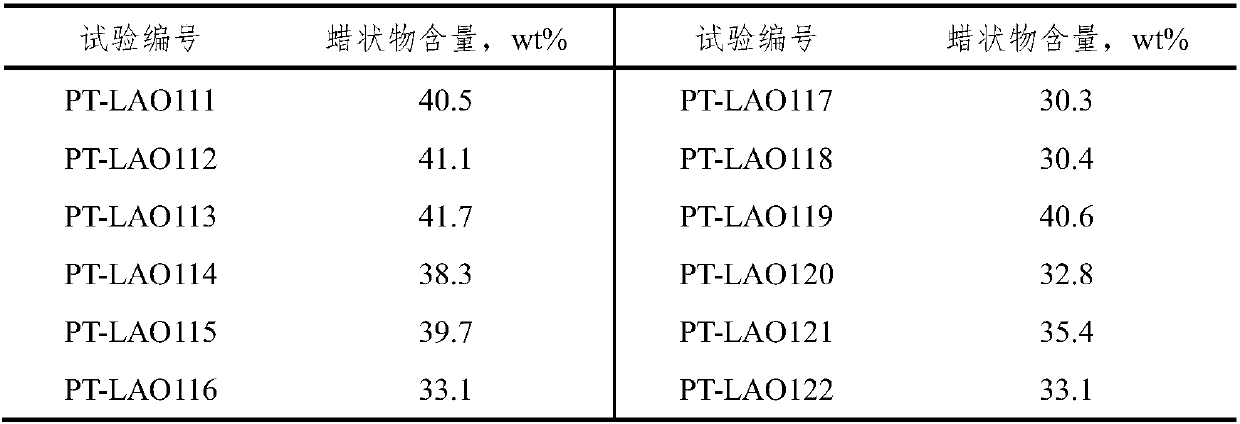

[0039] Table 2 Experimental results of ethylene oligomerization catalyzed by the new cocatalyst

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com