Electrolysis shaping method of TC4 titanium alloy turbine blade repairing layer

A technology of turbine blades and titanium alloys, applied in metal processing equipment, electrochemical processing equipment, manufacturing tools, etc., can solve problems such as electrolytic machining genetic errors, affecting final accuracy, and deteriorating repair accuracy, achieving good reliability and repeatability. Accuracy and reliability, the effect of uniform and flat contours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to allow those skilled in the art to understand the present invention more clearly and intuitively, the present invention will be further described below in conjunction with the accompanying drawings.

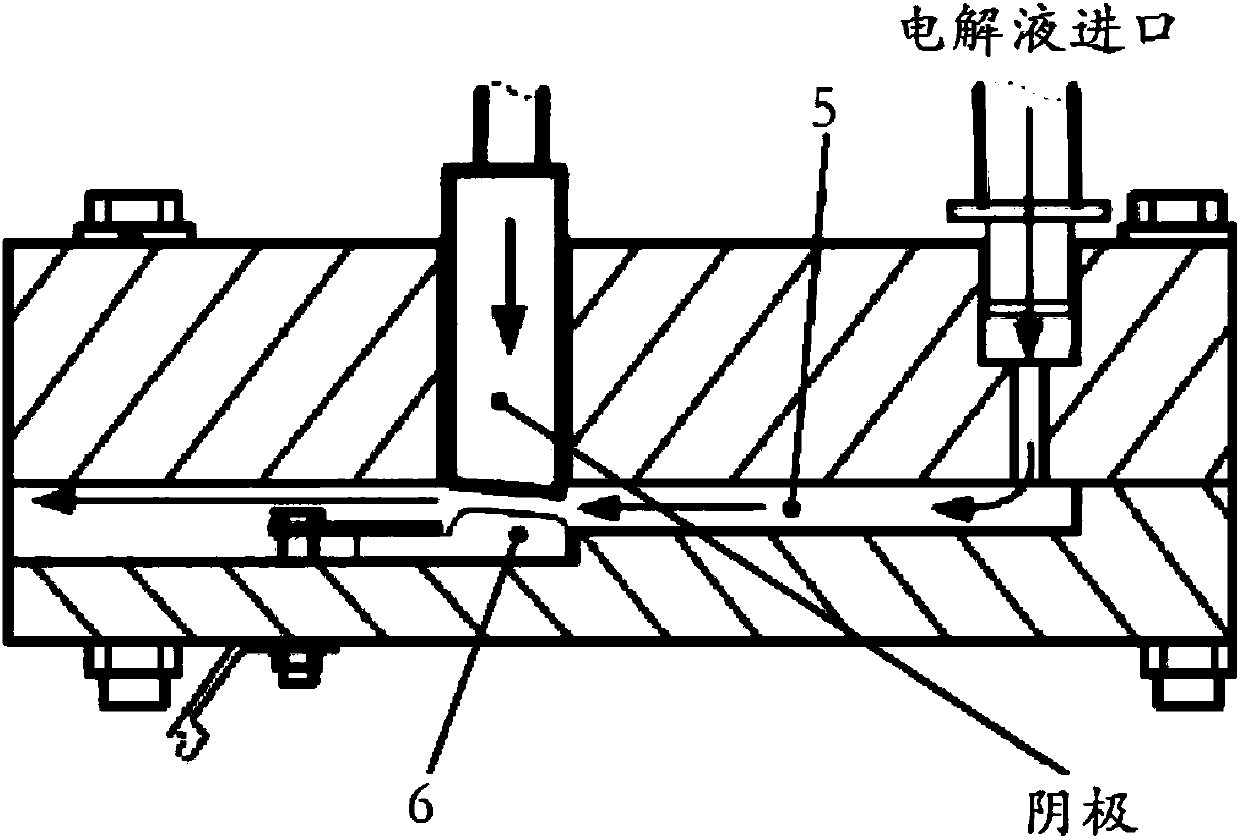

[0018] Such as Figure 1-2 Shown is a preferred embodiment of the invention.

[0019] An electrolytic modification method of a TC4 titanium alloy turbine blade repair layer, comprising the steps of:

[0020] S1. Establish an electrolytic machining system

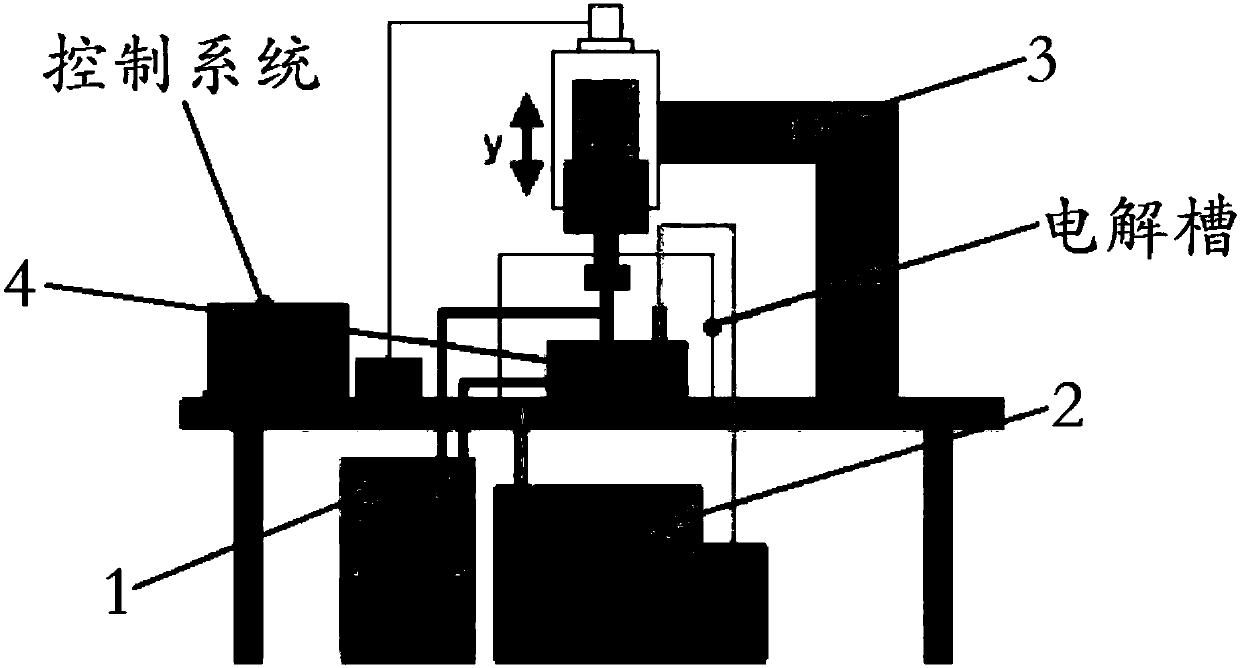

[0021] The self-made electrolytic machining system was used in the experiment, such as figure 1 shown. The system is equipped with a power supply system 1 for DC processing, the output voltage is 0-24V, the maximum output current is 2000A, and it has a short-circuit protection control function. The integrated control of power supply system 1, electrolyte circulation system 2 and machine tool displacement platform system 3 can realize automatic control and signal acquisition of parameters such as voltage, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com