Rust-removal-free water-based anti-corrosion coating and preparation method thereof

An anti-corrosion coating and anti-rust technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of health hazards, shortened anti-rust cycle, large labor force and cost, etc., to increase the performance of nodules and ensure long-term anti-corrosion stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

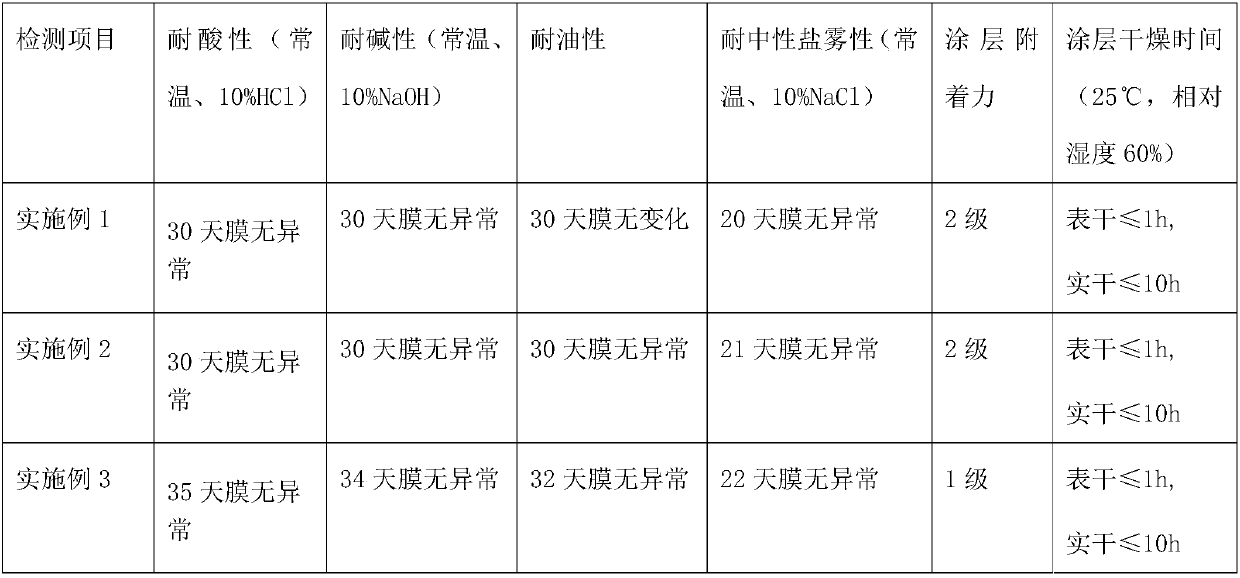

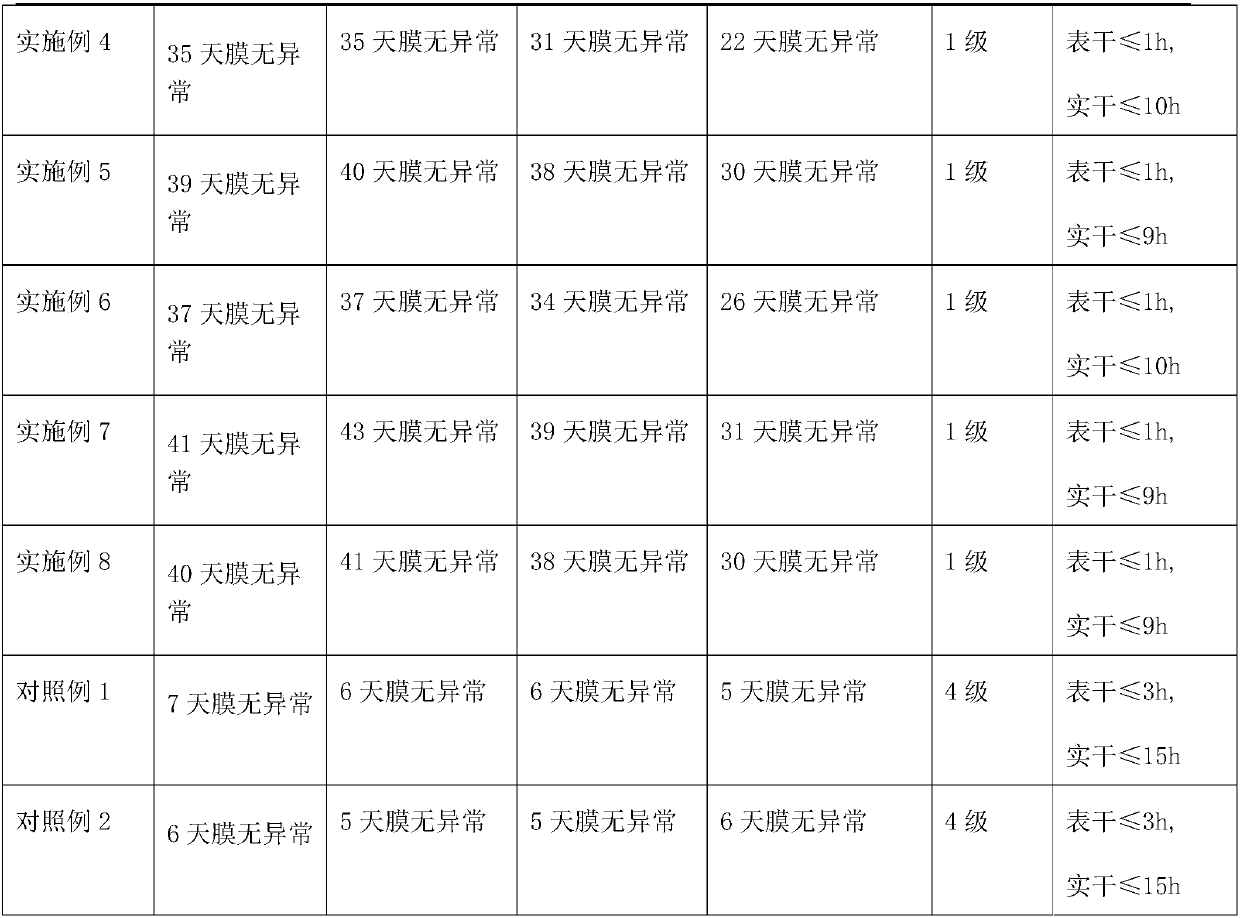

Examples

Embodiment 1

[0021] A kind of rust-free water-based anti-corrosion coating comprises the following components in parts by weight:

[0022] Acrylic emulsion 45 parts, zinc phosphate 5 parts, sodium nitrite 2 parts.

[0023] In the preparation method of the rust-free water-based anticorrosion coating described above, each component is mixed, then stirred and dispersed, ground and filtered to obtain the rust-free water-based anticorrosion coating. The stirring and dispersing speed is 1200 rpm, the dispersing time is 60 minutes, and the particle size after grinding is 20 μm-40 μm.

Embodiment 2

[0025] A kind of rust-free water-based anti-corrosion coating comprises the following components in parts by weight:

[0026] Acrylic emulsion 50 parts, zinc phosphate 6 parts, sodium nitrite 3 parts.

[0027] In the preparation method of the rust-free water-based anticorrosion coating described above, each component is mixed, then stirred and dispersed, ground and filtered to obtain the rust-free water-based anticorrosion coating. The stirring and dispersing speed is 1300 rpm, the dispersing time is 70 minutes, and the particle size after grinding is 20 μm-40 μm.

Embodiment 3

[0029] A kind of rust-free water-based anti-corrosion coating comprises the following components in parts by weight:

[0030] 45 parts of acrylic emulsion, 5 parts of zinc phosphate, 2 parts of sodium nitrite, 5 parts of zinc oxide and 2 parts of aluminum stearate powder.

[0031] In the preparation method of the rust-free water-based anticorrosion coating described above, each component is mixed, then stirred and dispersed, ground and filtered to obtain the rust-free water-based anticorrosion coating. The stirring and dispersing speed is 1200 rpm, the dispersing time is 60 minutes, and the particle size after grinding is 20 μm-40 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com