An oil well cement channeling inhibitor having an inorganic-organic interpenetrating network, a preparing method and cement slurry

A technology of interpenetrating network and oil well cement, which is applied in the field of preparation method and cement slurry, inorganic organic interpenetrating network oil well cement anti-channeling agent, can solve the problems of difficult construction on site, high construction risk, filling "sausage", etc. Wide temperature range, improved anti-channeling performance, improved adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

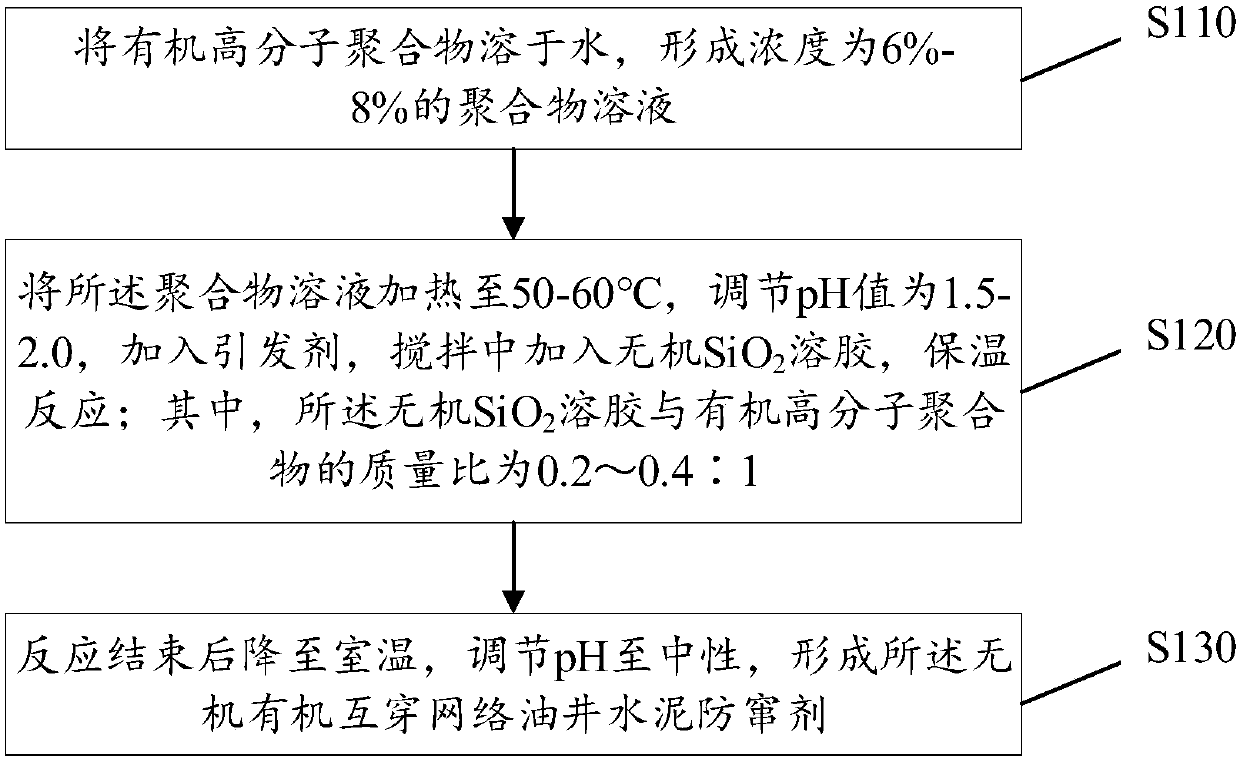

[0033] On the other hand, based on the same inventive concept, the embodiment of the present application provides a preparation method of the above-mentioned inorganic-organic interpenetrating network oil well cement anti-channeling agent, such as figure 1 As shown, it specifically includes the following steps:

[0034] Step S110: dissolving the organic polymer in water to form a polymer solution with a concentration of 6%-8%;

[0035] Among them, the concentration of the polymer solution is selected to be 6%-8%. On the one hand, it is limited by the dissolving ability of the polymer; middle.

[0036] The organic polymer is any one of polyvinyl alcohol or polyacrylamide. Preferably, the degree of polymerization of the polyvinyl alcohol is 1700-1800, and the degree of alcoholysis is 88% or 99%; the polyacrylamide is anionic.

[0037] Step S120: heating the polymer solution to 50-60°C, adjusting the pH value to 1.5-2.0, adding an initiator, and adding inorganic SiO while stir...

Embodiment 1

[0048] Take 10g of polyvinyl alcohol 1788, dissolve it in water to form a polymer solution with a concentration of 8%, heat it to 50°C, add hydrochloric acid, adjust the pH value to 1.5, add 0.1g of potassium persulfate, after the potassium persulfate is dissolved, stir Add 4.0g SiO in the process 2 Sol, silica sol solid content 20%, SiO 2 The particle size is 10nm, keep it for 30min, lower the temperature to 30°C, add ammonia water dropwise until the neutralization pH is 7.0, and obtain the inorganic organic interpenetrating network polymer anti-channeling agent, the code is G01.

[0049] The anti-channeling agent G01 obtained in this example is added to the cement slurry in an amount of 2%, and the cement slurry formula is: 100 g of G grade high sulfur-resistant cement, 4 g of fluid loss reducer BXF-200L (AF), anti-channeling Agent G01 2g, water 40g. To evaluate the anti-channeling performance, the test standard is the industry standard SYT 5504.5-2010 "Evaluation Method f...

Embodiment 2

[0053] Take 10g of polyvinyl alcohol 1788, dissolve it in water to form a polymer solution with a concentration of 7%, heat it to 55°C, add hydrochloric acid, adjust the pH value to 1.8, add 0.13g of ammonium persulfate, after the ammonium persulfate is dissolved, stir Add 3.0g SiO in the process 2 Sol, silica sol solid content 30%, SiO 2 The particle size is 20nm, keep it for 33min, lower the temperature to 30°C, add ammonia water dropwise until the neutralization pH is 7.0, and obtain the inorganic organic interpenetrating network polymer anti-channeling agent, the code is G02.

[0054] The anti-channeling agent G02 obtained in this example is added to the cement slurry in an amount of 2%, and the cement slurry formula is the same as in Example 1, only G01 in the example formula is replaced with G02. Anti-channeling performance is evaluated, the test method is the same as that of Example 1, and the results are shown in Table 2.

[0055] Table 2 Evaluation of anti-channelin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com