Production process of chlorinated paraffin

A technology of chlorinated paraffin and production process, which is applied in petrochemical modification, chemical instruments and methods, gas treatment, etc. It can solve the problems of less actual reaction volume, increase production cost, increase auxiliary materials, etc., and improve the utilization rate of raw material resources , shorten the reaction time, improve the effect of conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

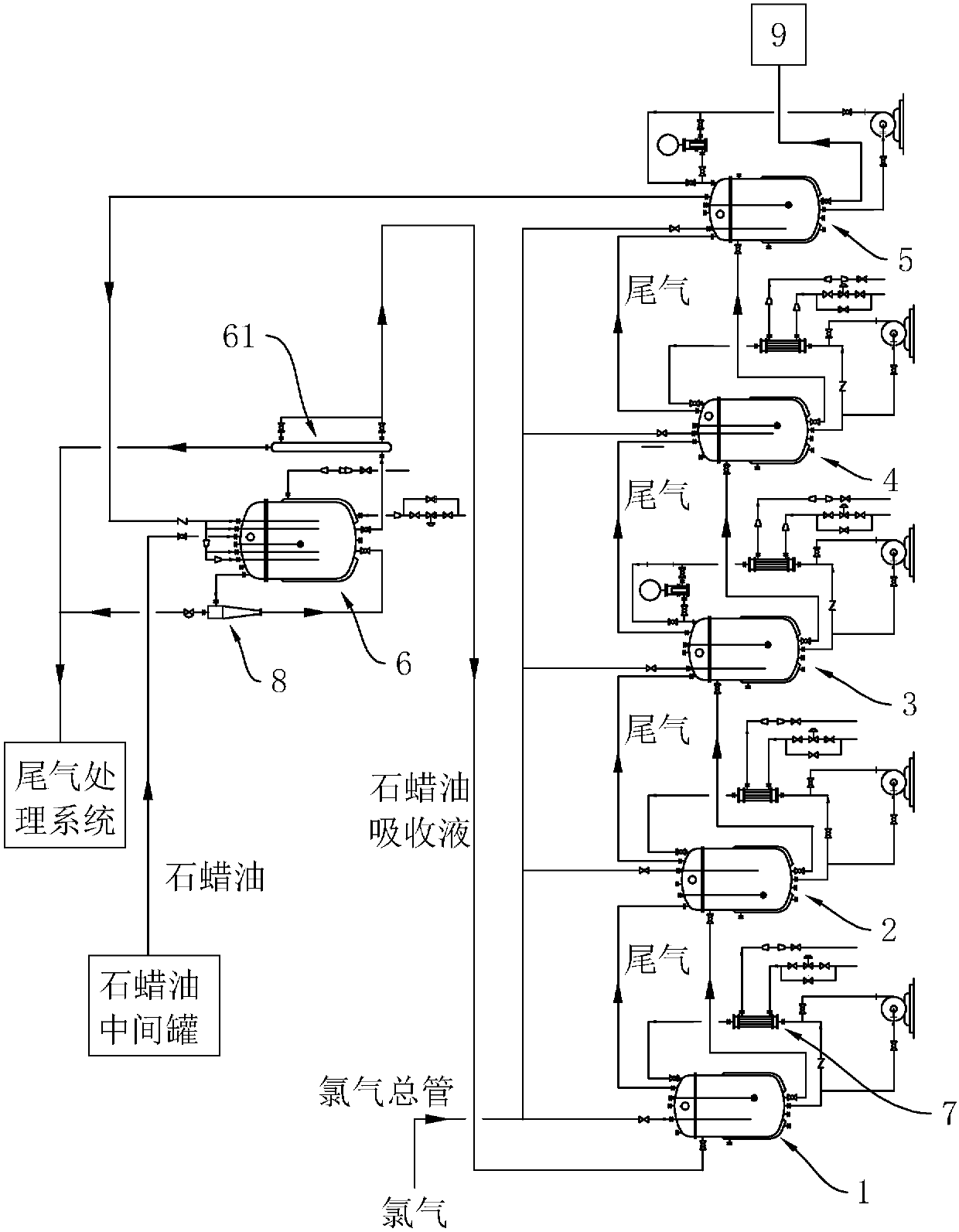

Method used

Image

Examples

Embodiment 1

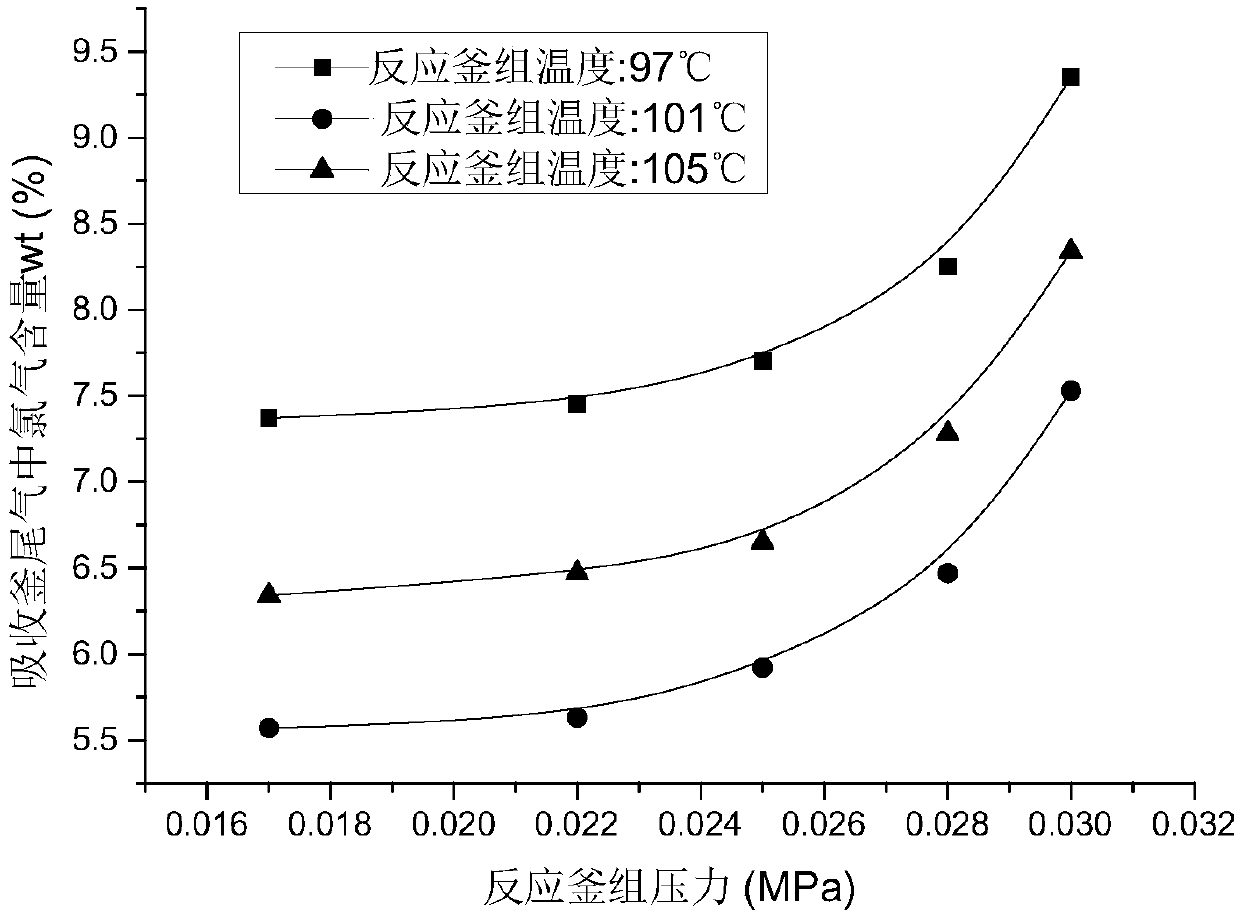

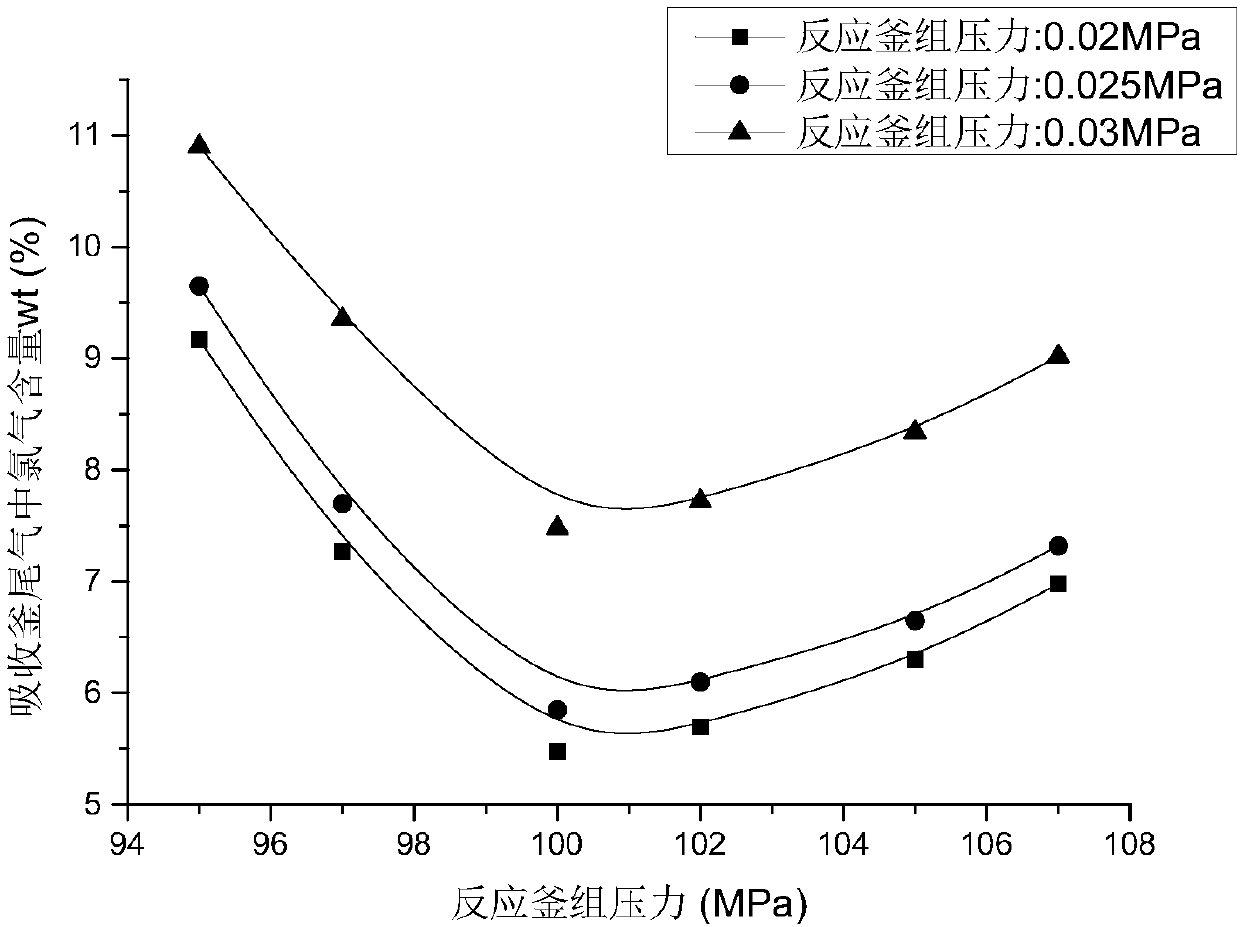

[0045] 10L / h pure paraffin oil continuously enters the first reaction kettle 1 through the paraffin oil inlet, and 0.17MPa pure chlorine gas is respectively passed into the first reaction kettle 1 to the fifth reaction kettle 5 from the chlorine gas pipe. The flow rate of pure chlorine gas 3m 3 / h; paraffin oil and chlorine in the first reactor 1 carry out chlorination reaction under photocatalysis, and the chlorinated paraffin and paraffin oil mixture that previous reactor obtains overflows in the reactor of rear stage, continue to carry out continuous reaction , wherein the chlorinated paraffin obtained at the bottom of the fifth reactor 5 enters the middle tank of chlorine wax and collects; the mixed tail gas of hydrogen chloride and chlorine generated by the reaction of the first reactor 1 to the fourth reactor 4 enters from the top of the previous reactor successively. In the latter reactor, the mixed tail gas obtained at the top of the fifth reactor 5 enters the absorpti...

Embodiment 2

[0048] 10L / h pure paraffin oil continuously enters the first reaction kettle 1 through the paraffin oil inlet, and 0.17MPa pure chlorine gas is respectively passed into the first reaction kettle 1 to the fifth reaction kettle 5 from the chlorine gas pipe. The flow rate of pure chlorine gas 3m 3 / h; paraffin oil and chlorine in the first reactor 1 carry out chlorination reaction under photocatalysis, and the chlorinated paraffin and paraffin oil mixture that previous reactor obtains overflows in the reactor of rear stage, continue to carry out continuous reaction , wherein the chlorinated paraffin obtained at the bottom of the fifth reactor 5 enters the middle tank of chlorine wax and collects; the mixed tail gas of hydrogen chloride and chlorine generated by the reaction of the first reactor 1 to the fourth reactor 4 enters from the top of the previous reactor successively. In the latter reactor, the mixed tail gas obtained at the top of the fifth reactor 5 enters the absorpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com