Method of producing metal ferronickel powder and diopside slag powder

A technology of diopside and metallic nickel, which is applied in the fields of metallurgy, inorganic non-metallic materials and solid waste treatment. It can solve the problems of poor stability, red mud slag reuse restrictions, and lateritic nickel slag difficult to use. It achieves low reaction temperature, Low energy consumption, compact and efficient process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

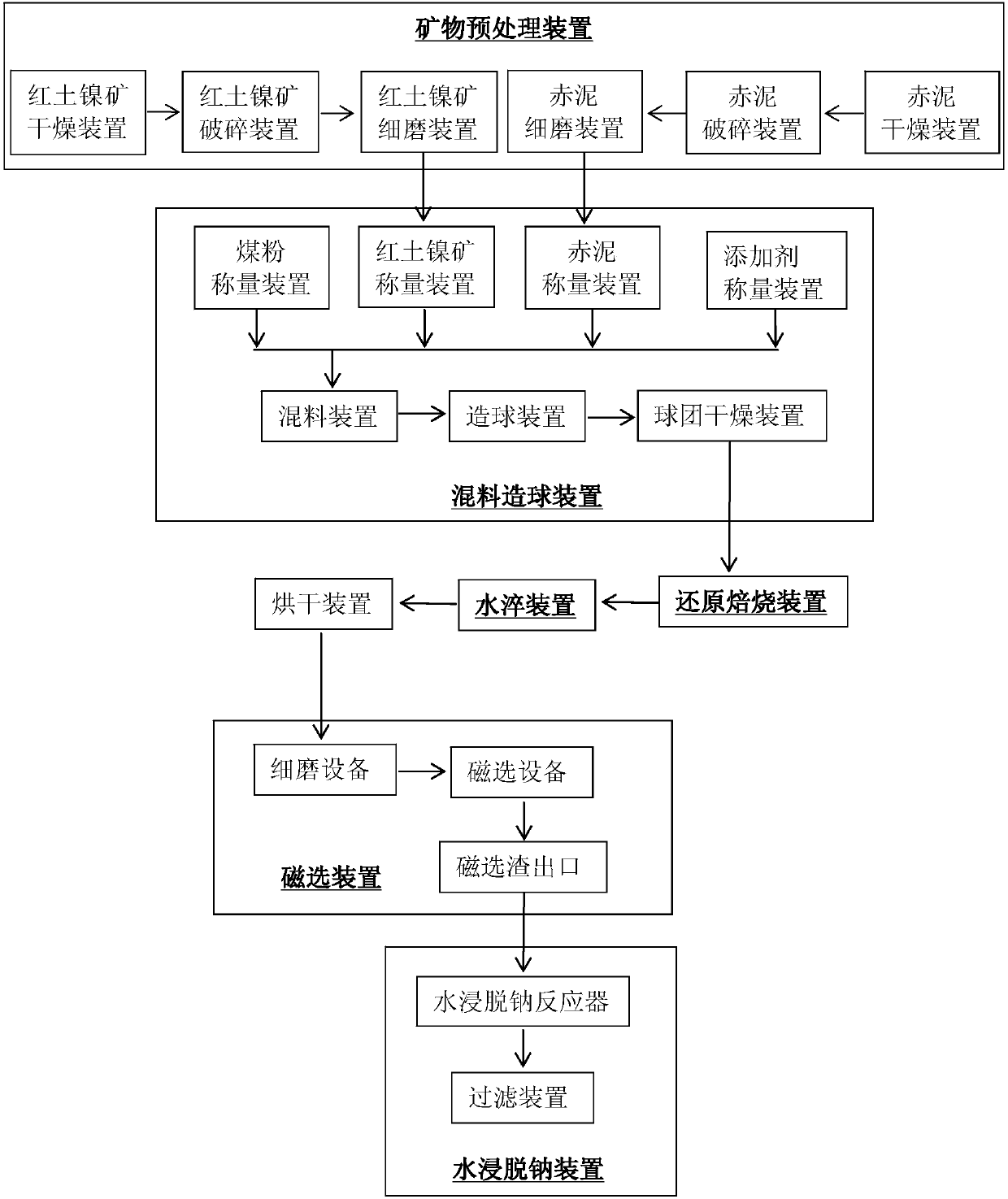

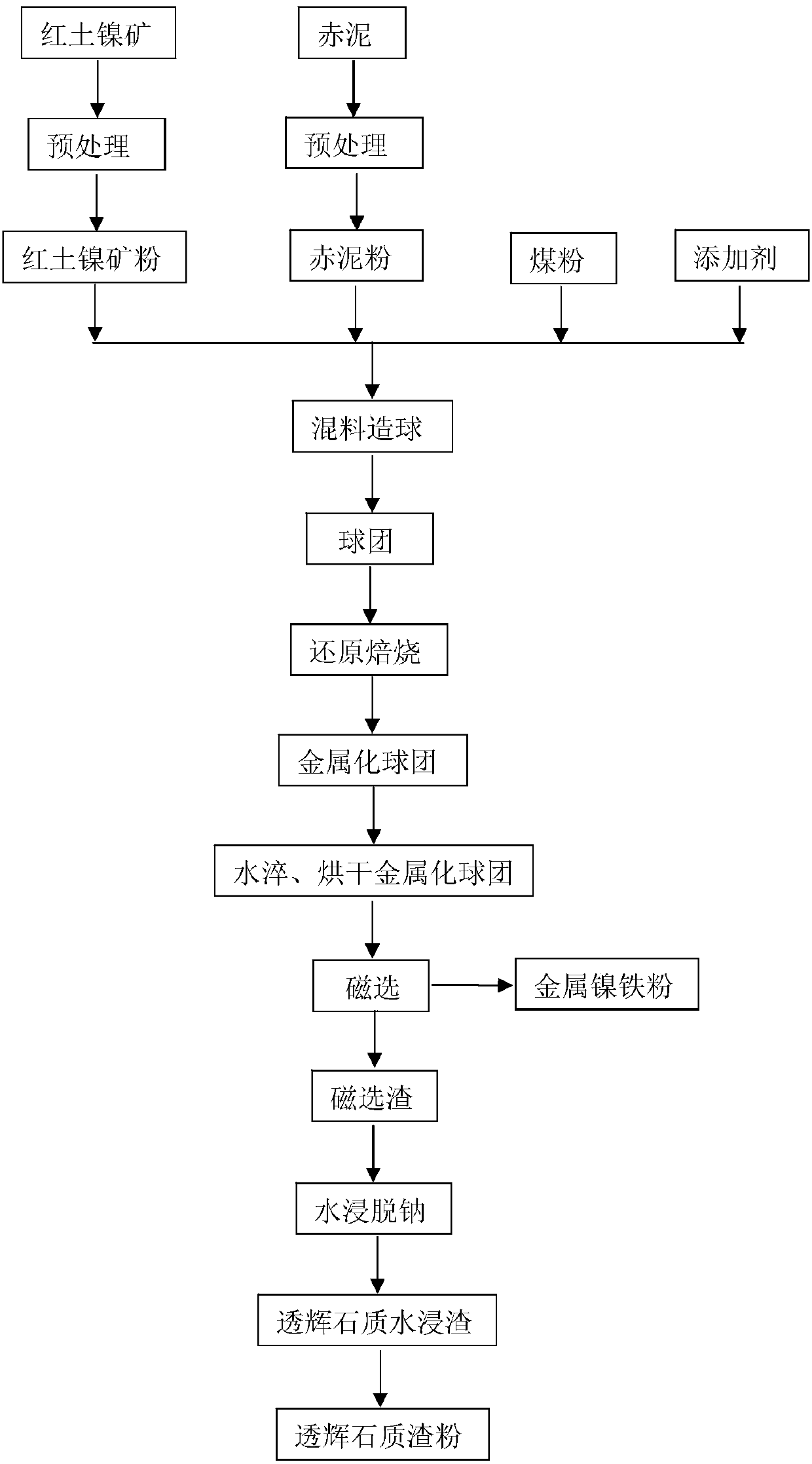

Method used

Image

Examples

Embodiment 1

[0070] The laterite nickel ore (each component and content is: Ni 1.25wt%, TFe 26.8wt%, SiO 2 38.6wt%, MgO21.2wt%), red mud (each component and content are: TFe 18.6wt%, CaO 42wt%, Al 2 o 3 18.4wt%, SiO 2 16.5wt%, Na 2 O+K 2 O 3.6wt%), dried at 105°C for 24h, and the dried material was finely ground to obtain laterite nickel ore powder and red mud powder. The laterite nickel ore powder and red mud powder are mixed to form the second mixed material, the second mixed material is composed of: 60 parts by weight of laterite nickel ore powder, 40 parts by weight of red mud powder, the second mixed material, reduced coal powder, The bentonite was mixed according to the mass ratio of 100:11:4 to obtain the first mixed material, and the first mixed material was put into a disc pelletizer to obtain pellets, and the diameter of the pellets was controlled to be 10 mm. Control of CaO, MgO, SiO in the first mixed material 2 The mass ratio is 0.5:0.5:1, while controlling (Na 2 O+K ...

Embodiment 2

[0073] The laterite nickel ore (each component and content is: Ni 1.16wt%, TFe 19.6wt%, SiO 2 42.3wt%, MgO17.65wt%), red mud (each component and content are: TFe 21wt%, CaO 41.2wt%, Al 2 o 3 11.4wt%, SiO 2 15.4wt%, Na 2 O+K 2O 2.6wt%), dried at 110° C. for 12 hours, and the dried material was finely ground to obtain laterite nickel ore powder and red mud powder. The laterite nickel ore powder and the red mud powder are mixed to form the second mixed material. The second mixed material is composed of: the laterite nickel ore powder is 65 parts by weight, and the red mud powder is 35 parts by weight. The second mixed material, reduced coal powder, The bentonite was mixed according to the mass ratio of 100:15:3 to obtain the first mixed material, and the first mixed material was put into a disc pelletizer to obtain pellets, and the diameter of the pellets was controlled to be 40mm. Control of CaO, MgO, SiO in the first mixed material 2 The mass ratio is 0.3:0.6:1, while co...

Embodiment 3

[0076] The laterite nickel ore (each component and content is: Ni 1.34wt%, TFe 24.6wt%, SiO 2 38.6wt%, MgO2 2.1wt%), red mud (each component and content are: TFe 17.5wt%, CaO 43.2wt%, Al 2 o 3 13.4wt%, SiO 2 17.8wt%, Na 2 O+K 2 O 4.6wt%), dried at 120° C. for 2 h, and the dried material was finely ground to obtain laterite nickel ore powder and red mud powder. The laterite nickel ore powder and the red mud powder are mixed to form the second mixed material. The second mixed material is composed of: the laterite nickel ore powder is 70 parts by weight, and the red mud powder is 30 parts by weight. The second mixed material, reduced coal powder, The pregelatinized starch was mixed according to the mass ratio of 100:18:4.4 to obtain the first mixed material, and the first mixed material was put into a disc pelletizer to obtain pellets, and the diameter of the pellets was controlled to be 15 mm. Control of CaO, MgO, SiO in the first mixed material 2 The mass ratio is 0.5:0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com