Method for recycling molybdenum and copper from tungsten smelting low grade molybdenum slag

A technology for removing molybdenum slag and molybdenum slag, which is applied to the improvement of process efficiency, photography process, instruments, etc., can solve the problems of high cost of extraction and crystallization consumption, long process flow, cumbersome process, etc., and achieves environmental friendliness and mature technology. , the effect of high metal recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

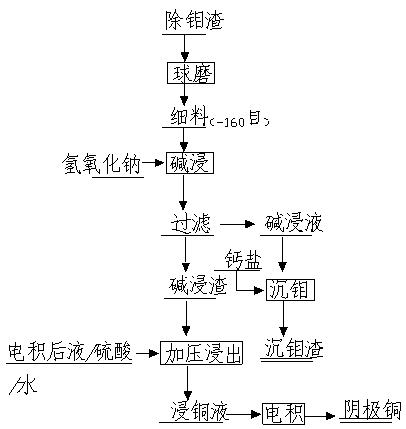

[0027] Such as figure 1 Shown, a kind of method that reclaims molybdenum and copper from tungsten smelting molybdenum slag, comprises the following steps:

[0028] A. Ball milling: Molybdenum removal slag fine material is obtained after ball milling and grading;

[0029] B. Molybdenum leaching: the molybdenum removal slag fine material obtained in step A is added to the leaching tank according to the liquid-solid ratio and water to mix, stir, and add alkaline solution to leaching molybdenum. filter residue, wash the filter residue with water to obtain washing water and molybdenum leaching residue, and return the washing water to the leaching ingredients to leaching molybdenum;

[0030] C, precipitated molybdenum: add calcium chloride or calcium hydroxide to the molybdenum immersion solution that step B obtains, make the molybdenum precipitation in the molybdenum solution form calcium molybdate product;

[0031] D. Copper leaching: Put the molybdenum leaching slag obtained in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com