Method for determining endosulfan in feed by gas chromatography-tandem mass spectrometry

A technology of tandem mass spectrometry and gas chromatography, which is applied in the detection field of pretreatment and gas chromatography-tandem mass spectrometry, can solve the problems of few reports on the detection of endosulfan, and achieve the effect of simple operation, economical process and strong universal applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

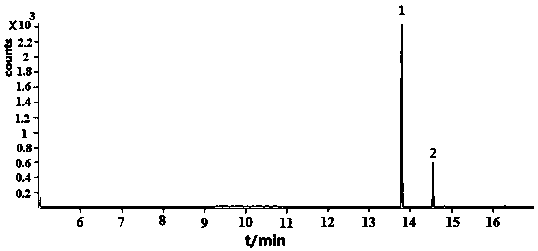

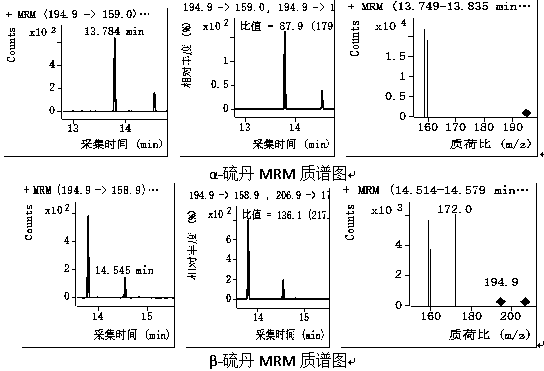

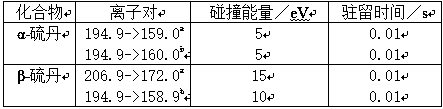

[0019] Example 1: Detection of 10 μg / Kg level addition blank feed sample

[0020] (1) Sample pretreatment steps: Take the feed pulverizer and crush it, pass it through a 0.25mm aperture (60 mesh) sieve, mix it thoroughly and put it into a grinding bottle for later use; accurately weigh 20g (accurate to 0.01g) of the crushed feed sample to In a 100 mL homogenizing cup, add 10 μg / Kg level standard, add 40 mL chromatographically pure acetonitrile and homogenize for 2 min; transfer the liquid to a funnel for filtration, take 10 mL of the filtrate and blow it to dryness with nitrogen in a test tube , add 1mL n-hexane to be purified; add 2 cm high anhydrous Na to the SPE cartridge 2 SO 4 , activated with 3mL n-hexane-acetone solution (volume ratio 10:1, the same below); transfer the concentrated solution to a small column, and then wash the nitrogen blowpipe with 2mL n-hexane-acetone solution 2~3 times each time, and wash The liquid was transferred into the column, eluted with 8 m...

Embodiment 2

[0024] (1) Sample pretreatment steps: Accurately weigh 25 g (accurate to 0.01 g) of crushed feed samples into a 100 mL homogenizing cup, add 50 mL of chromatographically pure acetonitrile and homogenize for 2 min; transfer the liquid to a funnel for filtration, and take Spin 10 mL of the filtrate in a 50 mL pear-shaped flask to dryness with a rotary evaporator, add 1 mL of n-hexane for purification; add 1 cm high anhydrous Na 2 SO 4 , activated with 2 mL n-hexane-acetone solution (volume ratio 10:1, the same below); transfer the concentrated solution to a small column, and wash the nitrogen blowpipe with 2 mL n-hexane-acetone solution 2 to 3 times each time, and place The washing solution was transferred to the column, and eluted with 10 mL of n-hexane-acetone solution. The filtrate was spun to dryness with a rotary evaporator, and the volume of n-hexane was adjusted to 1 mL, and passed through a 0.22 μm needle-type nylon filter membrane in a chromatographic injection bottle f...

Embodiment 3

[0026] Example 3: Detection of some feed samples

[0027] (1) Sample pretreatment steps: Take the feed and crush it with a pulverizer, pass it through a 0.25mm aperture (60 mesh) sieve, mix it thoroughly and put it into a grinding bottle for later use; accurately weigh 30g (accurate to 0.01g) of the crushed feed sample To a 100 mL homogeneous cup, add 60 mL of chromatographically pure acetonitrile and homogenize for 2 min; transfer the liquid to a funnel for filtration, take 10 mL of the filtrate and blow it to dryness with nitrogen in a test tube, add 2 mL of n-hexane to be purified; SPE small column Add 2 cm height of anhydrous Na 2 SO 4, activated with 3 mL n-hexane-acetone solution (volume ratio 10:1, the same below); transfer the concentrated solution to a small column, and then wash the nitrogen blowpipe with 2 mL n-hexane-acetone solution 2~3 times each time, and place Transfer the washing solution into the column, elute with 12 mL of n-hexane-acetone solution, blow t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com