A compact rectangular te 10 -Circular waveguide tm 01 Mode conversion device

A TE10-, rectangular waveguide technology, applied in the direction of waveguide devices, circuits, electrical components, etc., can solve the problems of complex overall structure, limited practical application, narrow working frequency band, etc., to achieve firm connection, reduce dielectric loss, and conversion efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

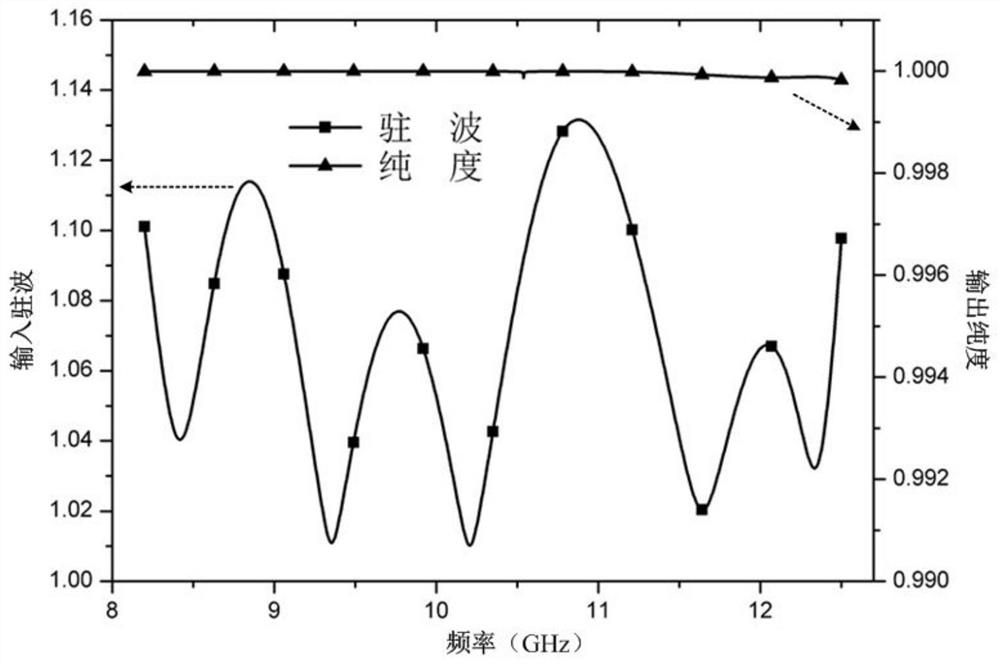

[0023] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

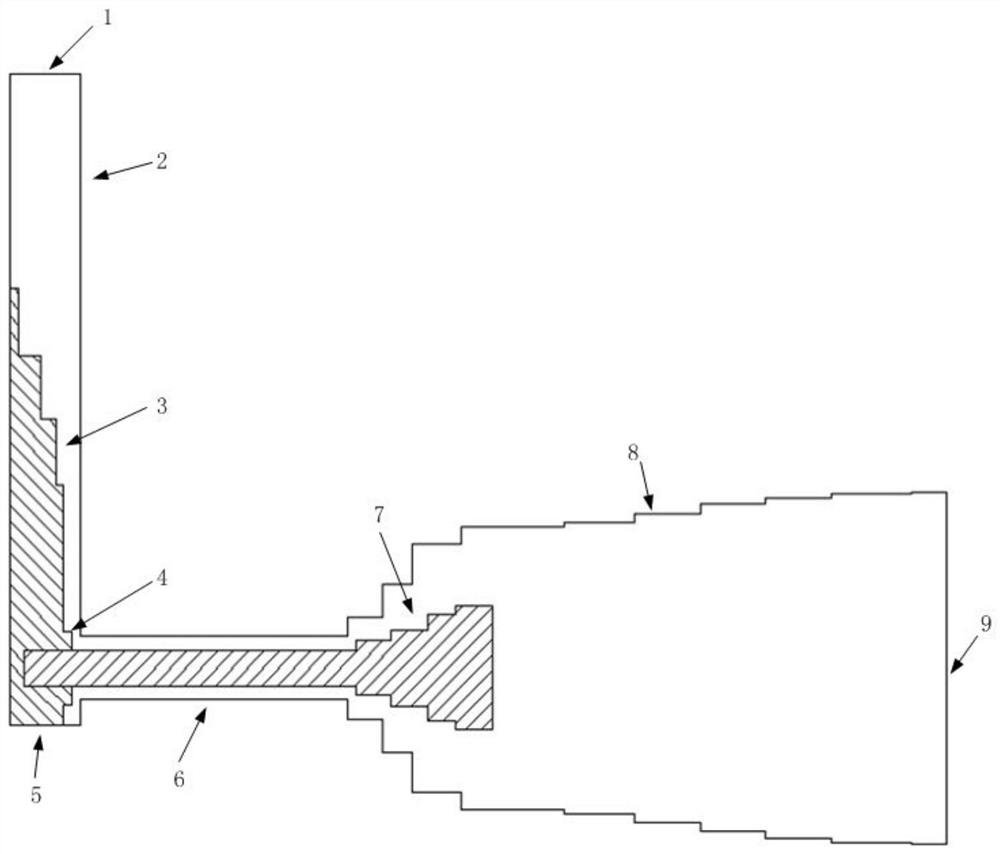

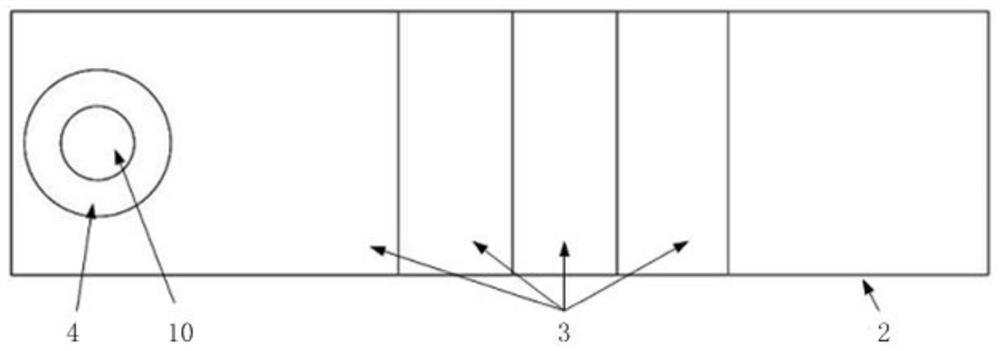

[0024] The cross-sectional structure of the embodiment of the present invention is as figure 1 As shown, including X-band standard BJ100 rectangular waveguide (waveguide size: wide side length 22.86mm, narrow side length 10.16mm), coaxial waveguide, stepped coaxial waveguide and stepped circular waveguide.

[0025] The standard rectangular waveguide is used to transmit X-band TE 10 Fundamental mode, one section of the standard rectangular waveguide uses a flange to connect with the signal source as the signal input end, and the other end is the short-circuit surface.

[0026] The rectangular waveguide is provided with a 4-stage metal ladder impedance matching structure with increasing length, and the step width is the same as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com