TiCl4 preparation process and system

A technology of preparation process and mass ratio, applied in the direction of titanium tetrachloride, titanium halide, etc., can solve problems such as difficulty, increased energy consumption, waste of titanium resources, etc., to improve the recovery rate of titanium, improve comprehensive utilization, and reduce chlorination The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

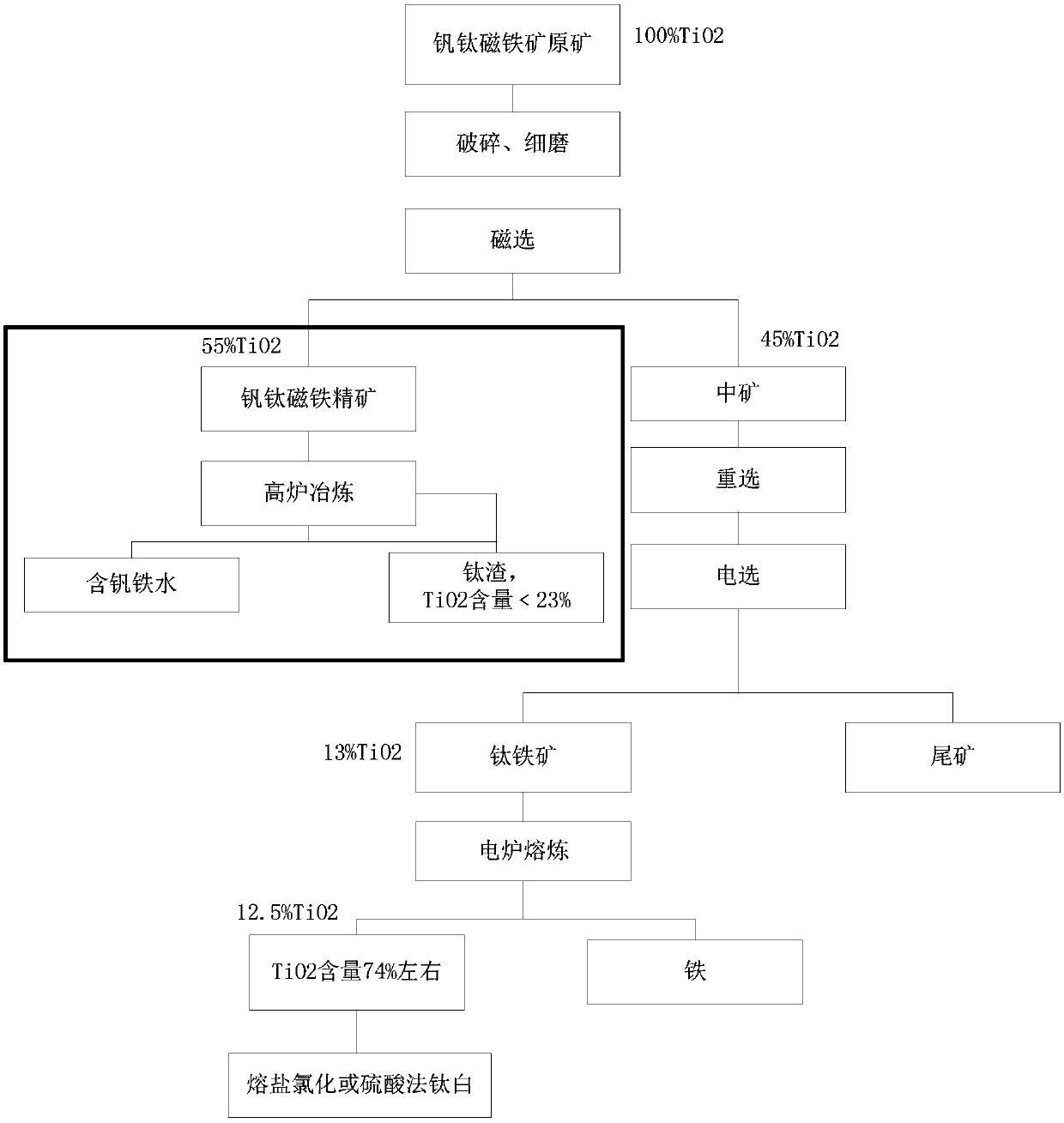

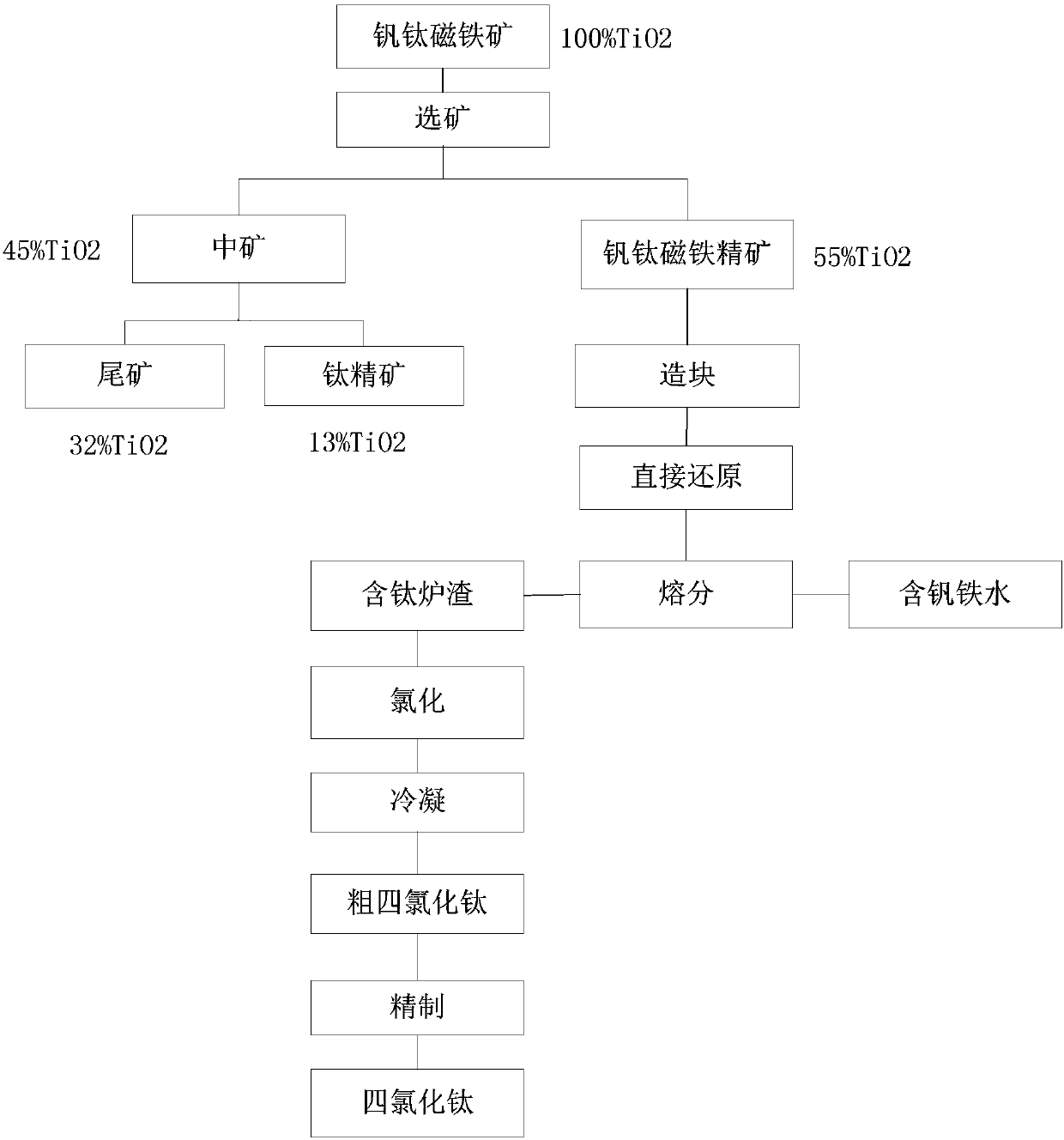

Problems solved by technology

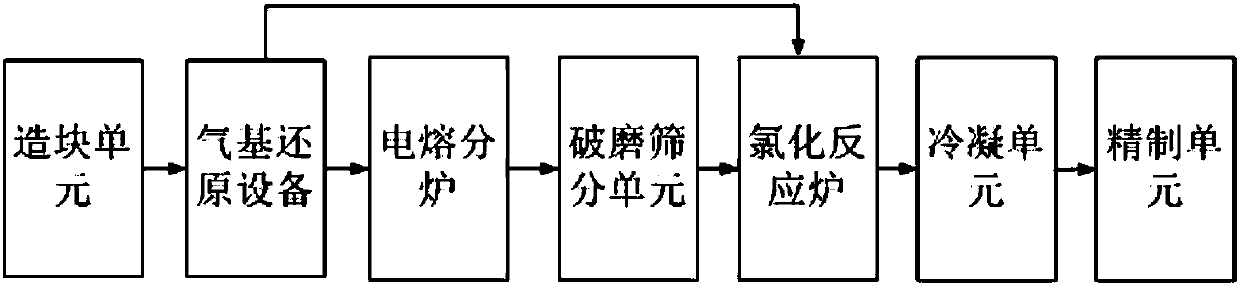

Method used

Image

Examples

Embodiment 1

[0055] The TiCl of the embodiment 1 of the present invention 4 The preparation process comprises the following steps:

[0056] Agglomeration: Mix vanadium-titanium magnetite concentrate, binder, and water at a mass ratio of 100:1:7.5 to obtain green pellets, which are dried, preheated, and roasted to obtain oxidized pellets. Among them, vanadium-titanium magnetite concentrate The main components and contents of the ore are shown in Table 1;

[0057] Table 1

[0058] TF

Fe 2 o 3

FeO

CaO

MgO

SiO 2

Al 2 o 3

V 2 o 5

TiO 2

MnO

54.55

54.41

21.22

0.56

3.58

3.98

3.26

0.65

10.50

0.51

[0059] Direct reduction: send the oxidized pellets into the shaft furnace for direct reduction, and obtain vanadium-titanium metallized pellets with a metallization rate of 89.65%. Gas effective gas volume ratio (CO+H 2 ) / (CO+H 2 +N 2 +CO 2 +H 2 O) = 0.8;

[0060] Melting: Feed the vanadium-titaniu...

Embodiment 2

[0068] The TiCl of the embodiment 2 of the present invention 4 The preparation process comprises the following steps:

[0069] Agglomeration: Mix vanadium-titanium magnetite concentrate, binder, and water at a mass ratio of 100:2:9 to obtain green pellets. The green pellets are dried, preheated, and roasted to obtain oxidized pellets. Among them, vanadium-titanium magnetite concentrate The main components and contents of ore are shown in Table 3;

[0070] table 3

[0071] TF

Fe2O3

FeO

V2O5

TiO2

MnO

CaO

MgO

SiO2

Al2O3

59.00

56.57

25.00

0.65

12.25

0.51

0.33

1.89

0.98

1.21

[0072]Direct reduction: send the oxidized pellets into the shaft furnace for direct reduction, and obtain vanadium-titanium metallized pellets with a metallization rate of 83.65%. Gas effective gas volume ratio (CO+H 2 ) / (CO+H 2 +N 2 +CO 2 +H 2 O) = 0.9;

[0073] Melting: Feed the vanadium-titanium metallized pellets a...

Embodiment 3

[0081] The TiCl of the embodiment 3 of the present invention 4 The preparation process comprises the following steps:

[0082] Agglomeration: Mix vanadium-titanium magnetite concentrate, binder, and water at a mass ratio of 100:2:9 to obtain green pellets, which are dried, preheated, and roasted to obtain oxidized pellets.

[0083] Direct reduction: send the oxidized pellets into the shaft furnace for direct reduction, and obtain vanadium-titanium metallized pellets with a metallization rate of 83.65%. Gas effective gas volume ratio (CO+H 2 ) / (CO+H 2 +N 2 +CO 2 +H 2 O) = 0.9;

[0084] Melting: Feed the vanadium-titanium metallized pellets and semi-coke into the melting furnace at a mass ratio of 100:5. The charge is heated to 1700°C in the melting furnace and kept at a constant temperature for 45 minutes to complete the separation of slag and iron to obtain titanium-containing slag.

[0085] Chlorination: The titanium slag after separation of slag and iron is crushed an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com