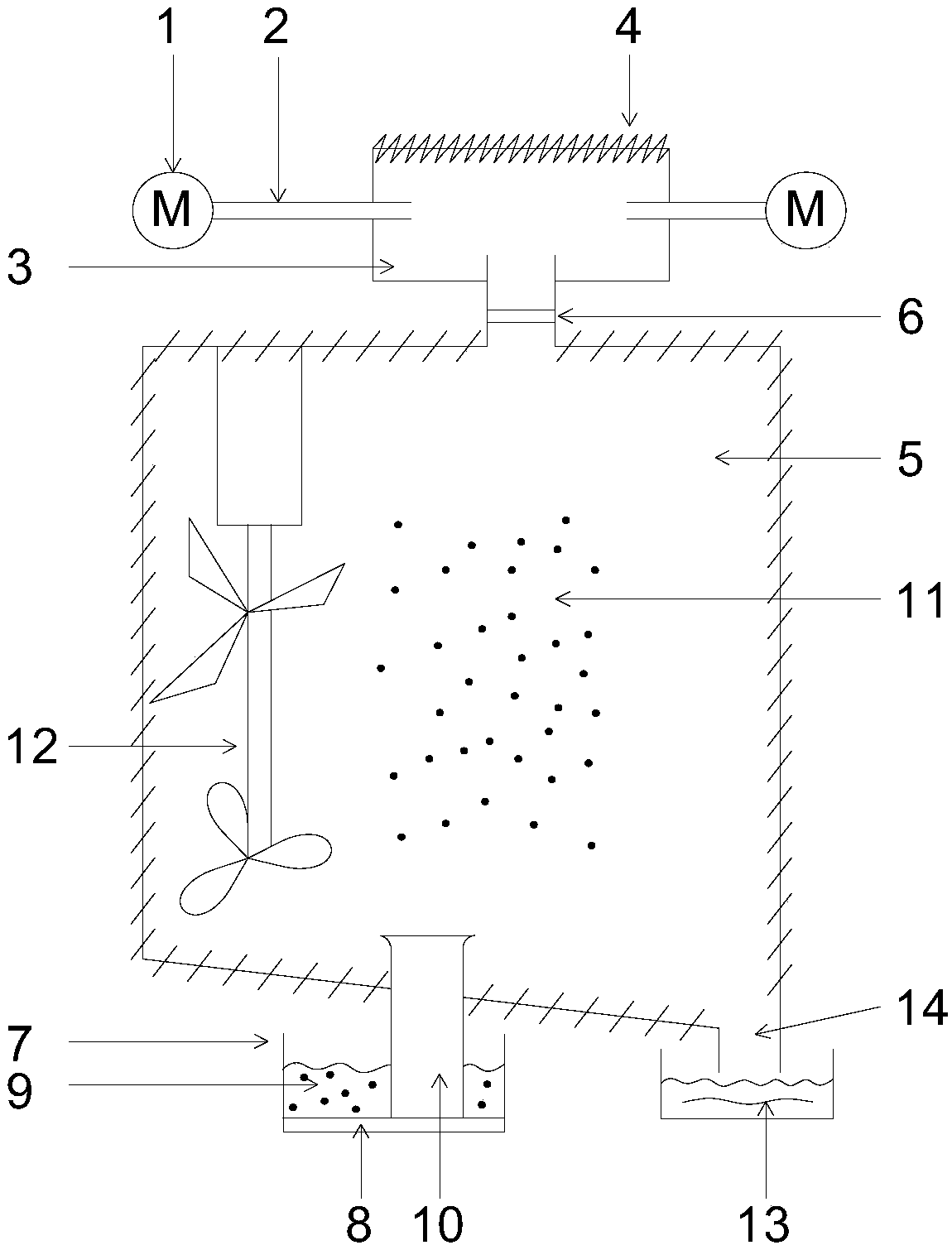

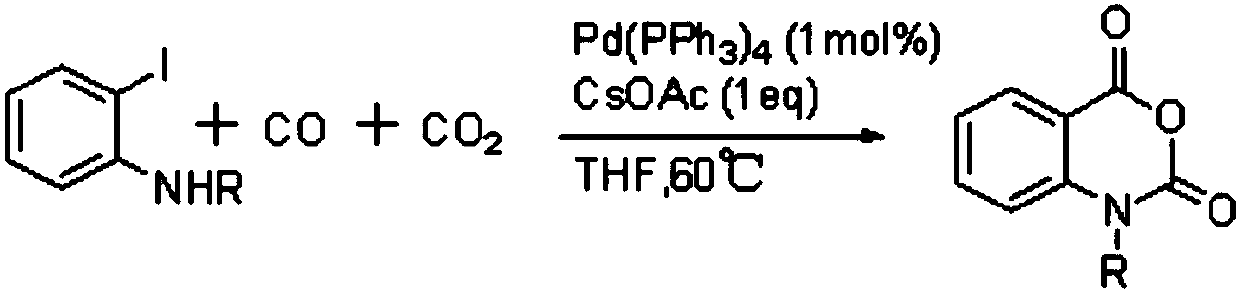

Device for converting CO and CO2 into isatoic anhydride

A technology of isatoic anhydride and CO2, applied in the direction of organic chemistry, can solve the problems of many by-products, low product purity, low conversion efficiency, etc., and achieve the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: Excessive waste gas CO, CO 2 Use the exhaust pump 1 to pass into the material buffer chamber 3 from the inlet port 2 with a material ratio of 1:1, heat it through the heating resistor 4 to keep the temperature at about 60 ° C, and after buffering treatment, wait for CO, CO 2 Thoroughly mix and suck the mixed gas into the adiabatic reaction chamber 5 together. Configure the DMF solution of o-iodoaniline, and add 5 mol% Pd(PPh3)4 (as a catalyst) and 2 times the equivalent of CsOAc powder into the solution to obtain a mixed reaction solution, which is added to the reaction solution preparation chamber 7. Turn on the magnetic stirrer 8 to drive the stirring bar 9 to fully mix the reaction solution while maintaining the temperature of the reaction solution at about 60°C. Under the action of the ultra-fine DMF atomizer 10, the reaction solution is sprayed into the air to form a mist reactant 11 with an average droplet diameter of 0.05-0.1 mm. In the adiabatic...

Embodiment 2

[0022] Embodiment 2. The difference between this embodiment and Embodiment 1 is that the ratio of reactants is different. In this embodiment, excess waste gas CO, CO 2 With exhaust pump 1, pass into material buffer chamber 3 from inlet channel 2 with the amount ratio of 1:1, configure the DMF solution of o-iodoaniline, and with the Pd of 1mol% (PPh3) 4 (as catalyst), 2 Double the equivalent of CsOAc powder is added to the solution to obtain a mixed reaction solution, which is added to the reaction solution preparation chamber 7 .

Embodiment 3

[0023] Embodiment 3. The difference between this embodiment and Embodiment 1 is that the ratio of reactants is different. In this embodiment, excess waste gas CO, CO 2With exhaust pump 1, pass into material buffer chamber 3 from inlet channel 2 with the amount ratio of 1:1, configure the DMF solution of o-iodoaniline, and with the Pd of 1mol% (PPh3) 4 (as catalyst), 1 Double the equivalent of CsOAc powder is added to the solution to obtain a mixed reaction solution, which is added to the reaction solution preparation chamber 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com