Fluoroplastic electric wire and cable and preparation method thereof

A wire and cable, fluoroplastic technology, applied in the field of new fluoroplastic wire and cable and its preparation, can solve the problems of poor chemical medium corrosion resistance, high temperature resistance and poor corrosion resistance of wires and cables, and achieve chemical medium corrosion resistance. Good, good resistance to mechanical damage, good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the above-mentioned fluoroplastic wire and cable comprises the following steps:

[0025] Step 1: Take the basic resin by weight, 30-80 parts; fluororubber elastomer, 15-50 parts; auxiliary crosslinking agent, 2-5 parts; rheological agent, 3-8 parts; acid absorber, 0.5- 2 parts; color masterbatch, 5-20 parts;

[0026] Step 2: After granulation by parallel twin-screw extruder, add a second-layer filter in the die area of the twin-screw, and then extrude into a pipe with a single-screw extruder, add a second-layer filter, and set the extrusion temperature In Zone 1 225-235°C, Zone 2 260-280°C, Zone 3 270-290°C;

[0027] Step 3: Treat the outer surface of the extruded pipe with infrared light with a wavelength of 700nm-1600nm at a distance of 5-10cm from the die of the extruder;

[0028] Step 4: The tube is cross-linked by cobalt 60 or electron accelerator 50-160KGy radiation, and the tube after radiation cross-linking is expanded 2-4 times at ...

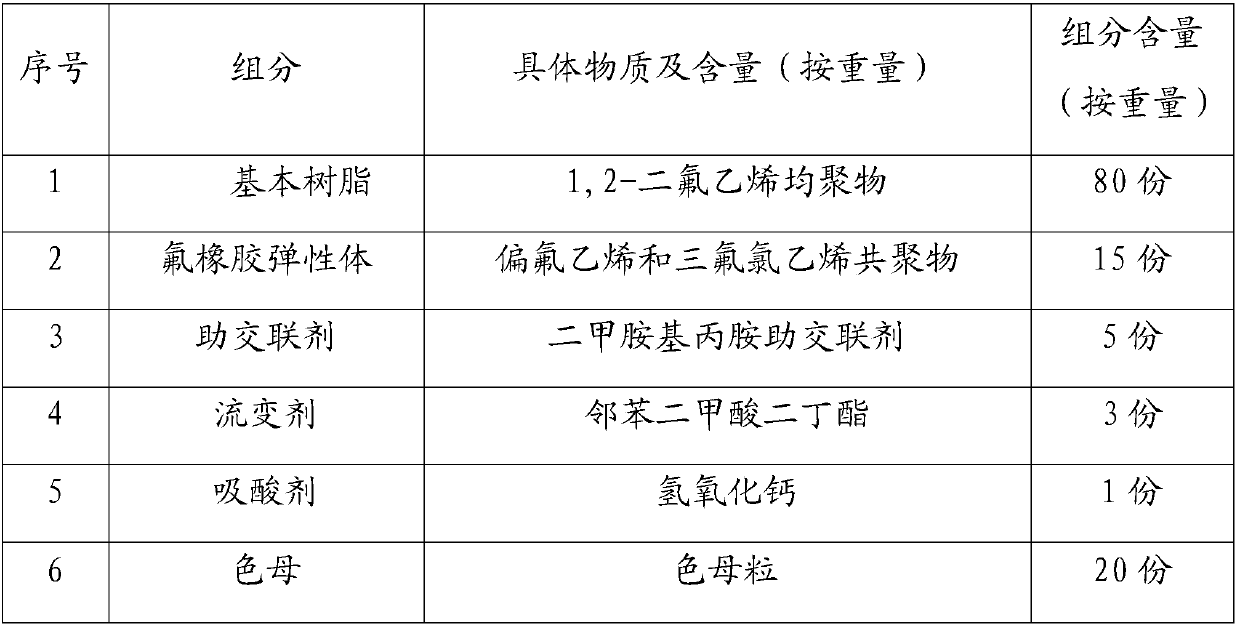

preparation Embodiment 1

[0030] The various components were weighed according to the weights listed in the table below.

[0031]

[0032] Step 2: After granulation by parallel twin-screw extruder, add a second-layer filter in the die area of the twin-screw, and then extrude into a pipe with a single-screw extruder, add a second-layer filter, and set the extrusion temperature In Zone 1 225-235°C, Zone 2 260-280°C, Zone 3 270-290°C;

[0033] Step 3: Treat the outer surface of the extruded pipe with infrared light with a wavelength of 700nm-1600nm at a distance of 5-10cm from the die of the extruder;

[0034] Step 4: The tube is cross-linked by cobalt 60 or electron accelerator 50-160KGy radiation, and the tube after radiation cross-linking is expanded 2-4 times at a temperature of 150-180°C.

[0035] The fluoroplastic wire and cable of the present invention has good insulation performance and can pass the test of UL224 standard;

[0036] The fluoroplastic wire and cable of the present invention h...

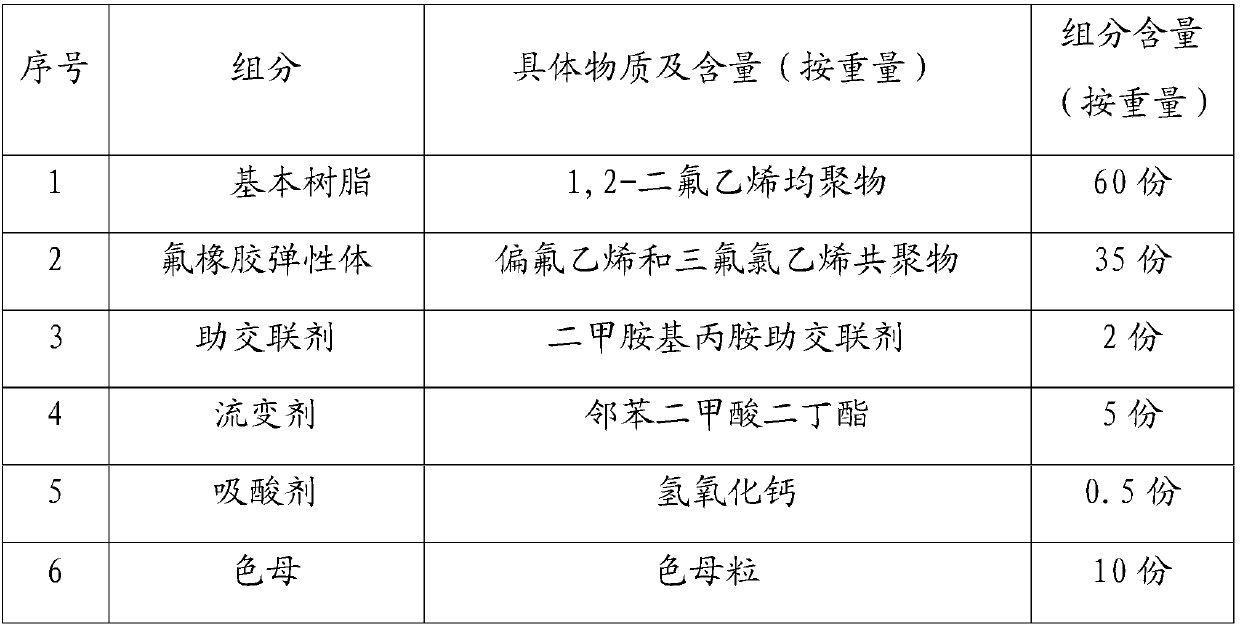

preparation Embodiment 2

[0042] The various components were weighed according to the weights listed in the table below.

[0043]

[0044] Step 2: After granulation by parallel twin-screw extruder, add a second-layer filter in the die area of the twin-screw, and then extrude into a pipe with a single-screw extruder, add a second-layer filter, and set the extrusion temperature In Zone 1 225-235°C, Zone 2 260-280°C, Zone 3 270-290°C;

[0045] Step 3: Treat the outer surface of the extruded pipe with infrared light with a wavelength of 700nm-1600nm at a distance of 5-10cm from the die of the extruder;

[0046] Step 4: The tube is cross-linked by cobalt 60 or electron accelerator 50-160KGy radiation, and the tube after radiation cross-linking is expanded 2-4 times at a temperature of 150-180°C.

[0047] The fluoroplastic wire and cable of the present invention has good insulation performance and can pass the test of UL224 standard;

[0048] The fluoroplastic wire and cable of the present invention h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com