Biodegradable rice hull powder based composite and preparation method thereof

A technology of biodegradable and composite materials, which is applied in the field of rice husk powder-based composite materials and its preparation, can solve the problems of inability to form, poor processing fluidity, economic benefits and biodegradable properties are not obvious, and achieve the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

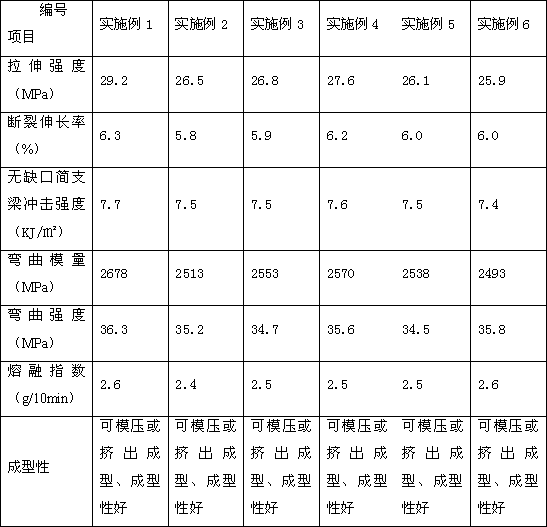

Examples

Embodiment 1

[0025] Take 500g rice husk powder, 25g glass fiber, 5g nano-montmorillonite, 5g aluminum titanate coupling agent, 5g antioxidant 1010, 120g polylactic acid, 10g EVA, 12g titanium dioxide, 10g PE wax Prepared.

[0026] The preparation method of the biodegradable rice husk-based composite material of the present embodiment is as follows:

[0027] S1. Add 500g of rice husk powder, 25g of glass fiber, and 5g of nano-montmorillonite into the high-speed mixer, set the working temperature of the high-speed mixer to 100°C, and mix and stir for 5 minutes to make a small amount of each material in all materials After the water is completely evaporated, open the cover of the high-speed mixer and wipe off the water droplets above it to prevent the water droplets from dripping back into the high-speed mixer to ensure product quality.

[0028] S2. Add 5 g of aluminum titanate coupling agent and 5 g of antioxidant 1010 into the high-speed mixer, close the cover, adjust the working temperatu...

Embodiment 2

[0033] Preparation of 500g rice husk powder, 30g glass fiber, 6g nano-montmorillonite, 6g aluminum titanate coupling agent, 6g antioxidant 168, 110g polylactic acid, 12g LLDPE, 13g titanium dioxide, 10g PE wax with diameter mesh greater than 60 mesh made.

[0034] The preparation method of the biodegradable rice husk-based composite material of the present embodiment is as follows:

[0035] S1. Add 500g of rice husk powder, 30g of glass fiber, and 6g of nano-montmorillonite into the high-speed mixer, set the working temperature of the high-speed mixer to 100°C, and mix and stir for 5 minutes to evaporate the moisture of each material in the material. Open the cover of the high-speed mixer and wipe off the water droplets above it to prevent the water droplets from dripping back into the high-speed mixer to ensure product quality.

[0036] S2. Add 6g of aluminum titanate coupling agent and 6g of antioxidant 168 into the high-speed mixer, close the cover, adjust the working temp...

Embodiment 3

[0041] Prepared by 500g rice husk powder, 20g glass fiber, 5g nano-montmorillonite, 5g aluminum titanate coupling agent, 5g antioxidant 168, 125g polylactic acid, 10g EVA, 15g titanium dioxide, 10g EVA wax with diameter mesh greater than 50 mesh become.

[0042] The preparation method of the biodegradable rice husk-based composite material of the present embodiment is as follows:

[0043] S1. Add 500g of rice husk powder, 20g of glass fiber, and 5g of nano-montmorillonite into the high-speed mixer, set the working temperature of the high-speed mixer to 100°C, and mix and stir for 5 minutes to evaporate the moisture of each material in the material. Open the cover of the high-speed mixer and wipe off the water droplets above it to prevent the water droplets from dripping back into the high-speed mixer to ensure product quality.

[0044] S2. Add 5 g of aluminum titanate coupling agent and 5 g of antioxidant 168 into the high-speed mixer, close the cover, adjust the working temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com