Corrosion inhibitor for oil and gas wells, and preparation method and application thereof

A technology for oil and gas wells and corrosion inhibitors, which is applied in chemical instruments and methods, earthwork drilling and production, boreholes/well components, etc. It can solve the problems of unstable decomposition of corrosion inhibitors, further improvement, and reduced corrosion inhibition performance. Achieve excellent corrosion inhibition effect, increase mutual solubility, and reduce interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

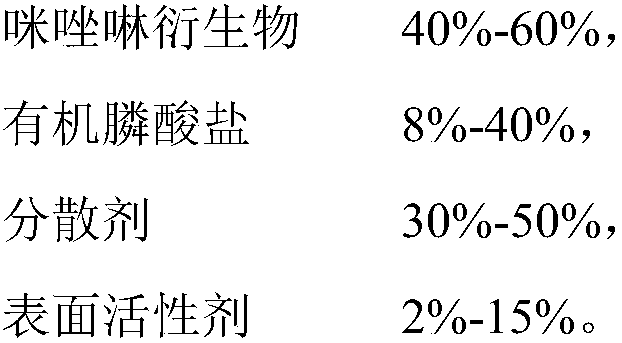

[0027] The present embodiment provides a corrosion inhibitor for oil and gas wells, and the corrosion inhibitor for oil and gas wells includes:

[0028]

[0029] This implementation also provides a preparation method of the oil and gas well corrosion inhibitor: according to the above ratio, imidazoline derivatives, 2-phosphonobutane-1,2,4-tricarboxylic acid, isopropanol and dodecylbenzenesulfonate It is prepared by mixing and stirring sodium and so on.

[0030] This implementation also provides the corrosion inhibitor for oil and gas wells to enhance the metal equipment in the high temperature and high salinity H 2 S-CO 2 -Cl - Application of corrosion resistance in the system.

Embodiment 2

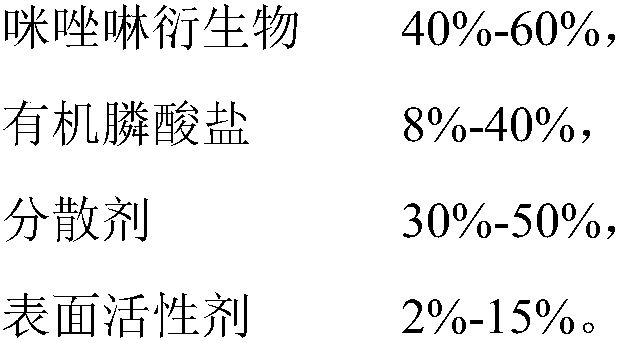

[0032] The present embodiment provides a corrosion inhibitor for oil and gas wells, and the corrosion inhibitor for oil and gas wells includes:

[0033]

[0034] This implementation also provides a preparation method of the oil and gas well corrosion inhibitor: according to the above ratio, imidazoline derivatives, 2-phosphonobutane-1,2,4-tricarboxylic acid, isopropanol and dodecylbenzenesulfonate It is prepared by mixing and stirring sodium and so on.

[0035] This implementation also provides the corrosion inhibitor for oil and gas wells to enhance the metal equipment in the high temperature and high salinity H 2 S-CO 2 -Cl - Application of corrosion resistance in the system.

Embodiment 3

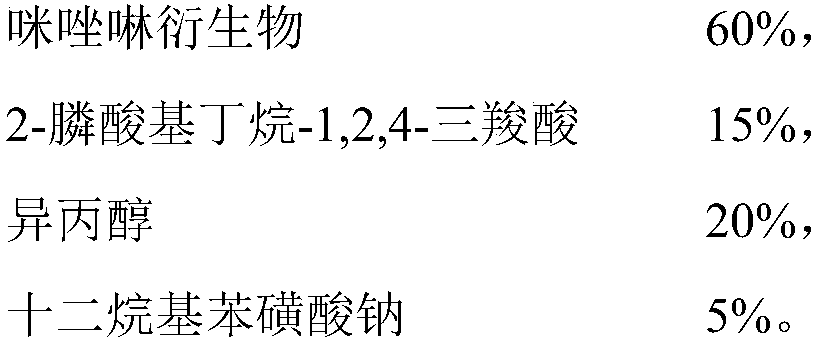

[0037] The present embodiment provides a corrosion inhibitor for oil and gas wells, and the corrosion inhibitor for oil and gas wells includes:

[0038]

[0039] This implementation also provides a preparation method of the oil and gas well corrosion inhibitor: according to the above ratio, imidazoline derivatives, 2-phosphonobutane-1,2,4-tricarboxylic acid, isopropanol and dodecylbenzenesulfonate It is prepared by mixing and stirring sodium and so on.

[0040] This implementation also provides the corrosion inhibitor for oil and gas wells to enhance the metal equipment in the high temperature and high salinity H 2 S-CO 2 -Cl - Application of corrosion resistance in the system.

[0041] The preparation methods of the imidazoline derivatives in the foregoing Examples 1-3 are as follows:

[0042] Step 1: React diethylenetriamine and oleic acid at 140-180°C for 3-4 hours, and vacuum dehydration to obtain intermediates. The specific reaction formula is as follows:

[0043]

[0044] Step 2:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com