Preparation method of Maillard reaction product of figs for cigarettes

The technology of Maillard reactant and fig is applied in the field of preparation of fig Maillard reactant for cigarettes, and can solve the problems of insufficient variety of aroma chemical components, single aroma type, insufficient improvement of cigarette aroma quality and the like, To achieve the effect of improving oral aftertaste, reducing throat irritation and improving smoke permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

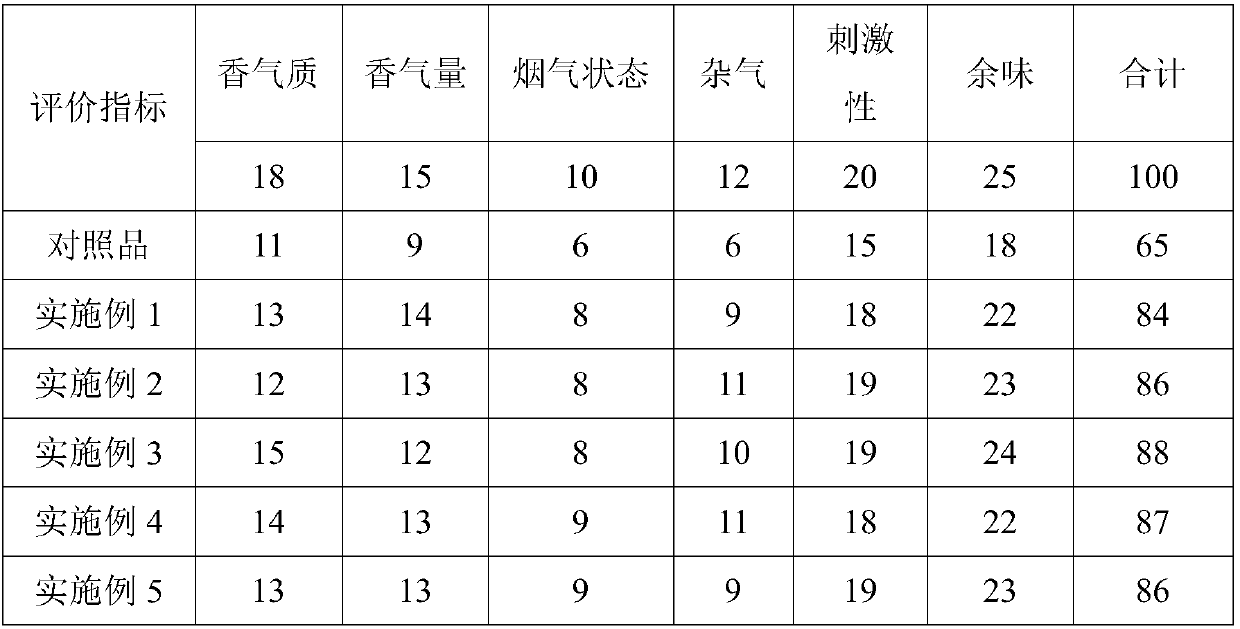

Examples

Embodiment 1

[0024] (1) Simply crush the fig raw material, and use a rotary roaster to continuously stir and roast at 85° C. for 5 hours, then lower the temperature to 55° C., and continue stirring and roasting for 8 hours.

[0025] (2) Add 8 times the amount of pure water to the raw fig raw material treated in step (1), and extract it dynamically under the condition of 65° C. for 3.5 hours.

[0026] (3) The initial extract of figs cooled to room temperature is dropped into a biological fermentation tank, and 0.2% of its weight of lactic acid bacteria, 1.0% of glucose and 10% of 95% food grade alcohol are added, at 30°C, stirring speed 60r / min Under conditions, the anaerobic fermentation was continued for 7 days.

[0027] (4) After the anaerobic fermentation, add 95% ethanol solution 2.5 times its weight to the fermentation broth, stir for 30 minutes, and let stand at room temperature for 24 hours.

[0028] (5) Filter the alcohol precipitation solution obtained in step (4) with a 100nm ce...

Embodiment 2

[0036] (1) Simply crush the fig raw material, and use a rotary roaster to continuously stir and roast at 95° C. for 3 hours, then lower the temperature to 50° C., and continue stirring and roasting for 7 hours.

[0037] (2) Add 9 times the amount of pure water to the raw fig raw material treated in step (1), and extract it in a dynamic countercurrent flow at 75°C for 2 hours.

[0038] (3) The initial extract of figs cooled to room temperature is dropped into a biological fermenter, and 0.25% of its weight of lactic acid bacteria, 0.8% of glucose and 7.5% of 95% food-grade alcohol are added, at 28°C, stirring speed 40r / min Under conditions, the anaerobic fermentation was continued for 5 days.

[0039] (4) After the anaerobic fermentation is finished, add 95% ethanol solution twice its weight to the fermentation broth, stir for 30 minutes, and let stand at room temperature for 36 hours.

[0040] (5) Filter the alcohol precipitation solution obtained in step (4) with a 100nm cer...

Embodiment 3

[0048] (1) Simply crush the fig raw material, and use a rotary roaster to continuously stir and roast at 90° C. for 3 hours, then lower the temperature to 60° C., and continue stirring and roasting for 6 hours.

[0049](2) Add 8 times the amount of pure water to the fig raw material treated in step (1), and conduct dynamic countercurrent extraction at 75° C. for 2 hours. After the extraction, filter through a 100-mesh sieve to obtain the initial fig extract.

[0050] (3) The initial extract of figs cooled to room temperature is dropped into a biological fermentation tank, and 0.3% of its weight of lactic acid bacteria, 0.9% of glucose and 7.5% of 95% food grade alcohol are added, at 31 ° C, stirring speed 35r / min Under conditions, the anaerobic fermentation was continued for 5 days.

[0051] (4) After the anaerobic fermentation is finished, add 95% ethanol solution 3 times its weight to the fermentation broth, stir for 30 minutes, and let stand at room temperature for 30 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com