Preparation method for improving dyeing depth of natural dye and reactive dye of wool

A technology of natural dyes and reactive dyes, applied in the field of improving the dyeing depth of wool natural dyes and reactive dyes, can solve the problems of large amount of ethanolamine, uneven dyeing, etc., achieve low loss rate, increase dyeing depth, and low implementation cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

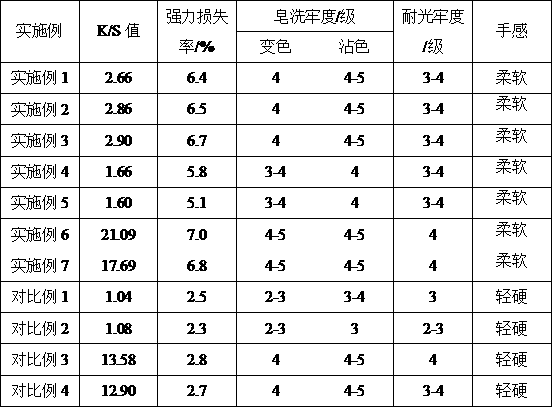

Examples

preparation example Construction

[0019] As shown in the examples, the present invention is a preparation method for improving the dyeing depth of wool natural dyes and reactive dyes, and the preparation method comprises the following steps:

[0020] (1) Wool pretreatment: soak the wool fiber in a solution composed of sodium citrate, sodium ethoxide, penetrant and water, and treat it at 30-50°C for 20-40min, the mass fraction of sodium citrate is 0.02-0.06% , the mass fraction of sodium ethoxide is 0.01-0.04%, the mass fraction of penetrant is 0.01-0.05%, and the rest is water;

[0021] (2) Acid neutralization and water washing: the wool fiber pretreated in step (1) is neutralized with an appropriate amount of acid and washed with water;

[0022] (3) Dyeing: dyeing the wool fibers prepared in step (2) with dyestuffs.

[0023] Wherein: in the step (1), the sum of the mass fractions of sodium citrate and sodium ethylate ranges from 0.03-0.08%; the penetrating agent is sodium isooctyl alcohol polyoxyethylene eth...

Embodiment 1

[0026] First, immerse 10Kg wool yarn in a pretreatment solution consisting of 0.05Kg sodium citrate, 0.02Kg sodium ethoxide, 0.02Kg penetrant OPE and 99.92Kg water. The immersion temperature is 45°C, and the immersion time is 30min. The pretreatment is completed. Finally, through acid neutralization and water washing, the pH value of the wool yarn is adjusted to neutral; then, the above wool yarn is dipped in 150Kg dyeing solution composed of 0.20Kg amaranth natural dye and an appropriate amount of water, and the dyeing solution is Raise the temperature to 80°C and keep at the temperature for 60 minutes; after the dyeing is completed, wash and dry to obtain red dyed wool yarn.

Embodiment 2

[0028] First, immerse 10Kg wool yarn in a pretreatment solution consisting of 0.06Kg sodium citrate, 0.02Kg sodium ethoxide, 0.04Kg penetrant OPE and 99.88Kg water. The immersion temperature is 30°C and the immersion time is 40min; the pretreatment is completed Finally, through acid neutralization and water washing, the pH value of the wool yarn is adjusted to neutral; then, the above wool yarn is dipped in 150Kg dyeing solution composed of 0.20Kg amaranth natural dye and an appropriate amount of water, and the dyeing solution is Raise the temperature to 80°C and keep at the temperature for 60 minutes; after the dyeing is completed, wash and dry to obtain red dyed wool yarn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com