Method for detecting positions of cracks in diamond compacts

A technology for diamond composite sheets and internal cracks, which is applied in the direction of testing composite materials, measuring devices, and optical testing for flaws/defects. Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

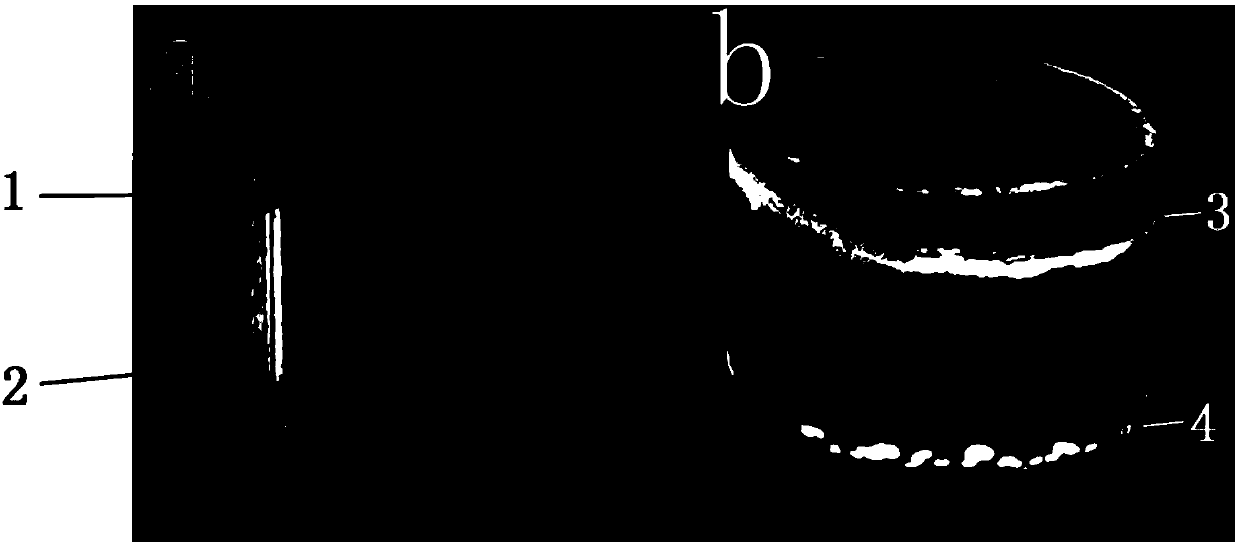

[0036] A method for detecting the position of cracks inside a diamond composite sheet. The diamond composite sheet includes polycrystalline diamond and a diamond composite sheet substrate, wherein the polycrystalline diamond is sintered on the diamond composite sheet substrate through high temperature and high pressure sintering.

[0037] The matrix of the diamond compact is a tungsten carbide matrix, the matrix of the diamond compact contains cobalt with a mass fraction of 8% to 10%, and the diamond compact is completely soaked in copper sulfate with a concentration of 10g / L In the solution, take it out after soaking for 2 minutes, rinse it slightly with water, you can see that the diamond composite sheet is divided into copper-plated and non-copper-plated areas, and the dividing line between the two areas is the matrix of the diamond composite sheet during welding. location of internal cracks.

[0038] In the present invention, the copper plated area is shown as red, light r...

Embodiment 2

[0041] A method for detecting the internal crack position of a diamond composite sheet, the conditions are the same as in Example 1, except that the diamond composite sheet is soaked in a copper nitrate solution with a concentration of 50g / L for 50 seconds, and the diamond composite sheet The matrix contains cobalt with a mass fraction of 5% to 8%. As a result, it is found that the position of the internal crack detected by the method of the present invention is consistent with the position of the internal crack detected by the heat resistance test (fluorescence defect detection method), thus it can be seen that the detection method of the present invention is accurate.

Embodiment 3

[0043] A method for detecting the internal crack position of a diamond composite sheet, the conditions are the same as in Example 1, except that the diamond composite sheet is soaked in a copper chloride solution with a concentration of 1g / L for 30 minutes, and the diamond composite sheet The sheet substrate contains cobalt with a mass fraction of 10% to 12%. As a result, it is found that the position of the internal crack detected by the method of the present invention is consistent with the position of the internal crack detected by the heat resistance test (fluorescence defect detection method), thus it can be seen that the detection method of the present invention is accurate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com