Material high-temperature thermophysical parameter rapid measurement method

A technology of physical parameters and measurement methods, applied in the direction of material thermal conductivity, material thermal development, etc., can solve the problem of only one-dimensional measurement of a certain thermal physical parameter, poor method versatility, complicated control, etc., to achieve method versatility Good, low cost, large measurement range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and through the specific embodiment of material high-temperature thermophysical parameter measurement, the present invention is described in further detail, following embodiment is descriptive only, non-limitative, can not limit the protection scope of the present invention with this.

[0032] Carry out the implementation of specific case according to technical scheme of the present invention and step, as follows:

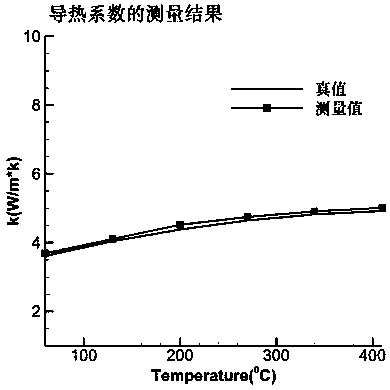

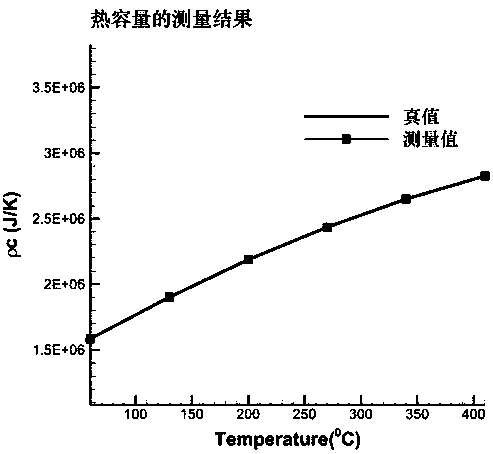

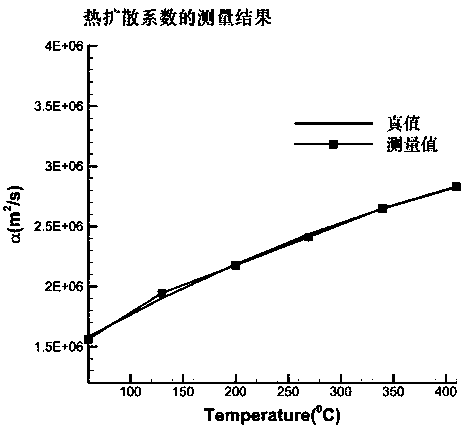

[0033] The bottom of the material to be tested is heated by constant uniform heat flow Q=1e+5W / m 2 , the rest of the surface is adiabatic surface, the ultrasonic probe is placed on the upper end surface, and the pulsed ultrasonic wave is excited by vertical incidence. Based on the measurement of the change of the echo propagation time of the bottom surface, the thermal conductivity and heat capacity of the material are inverted by solving the thermal / acoustic coupling inverse problem. Or thermal diffusivity and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com