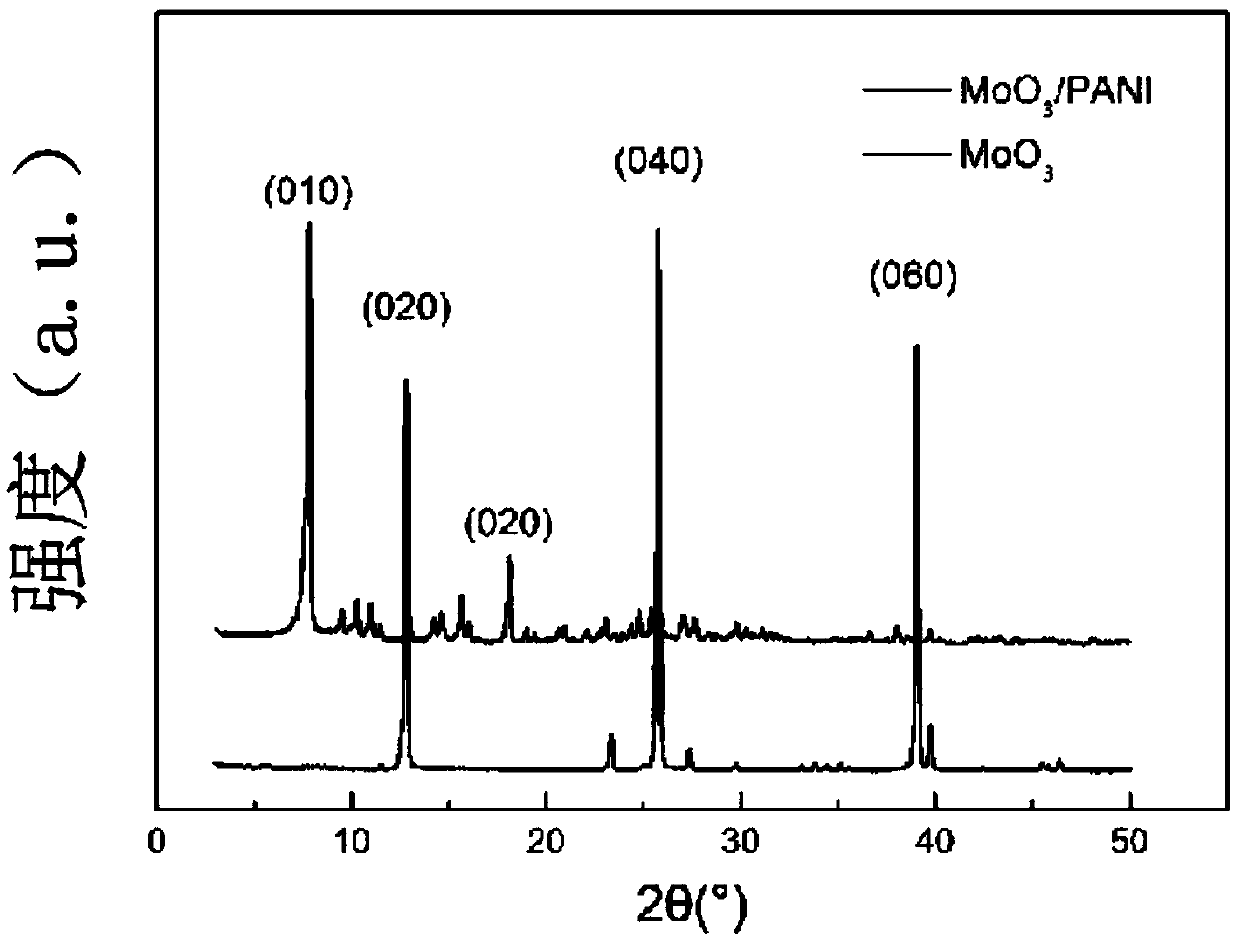

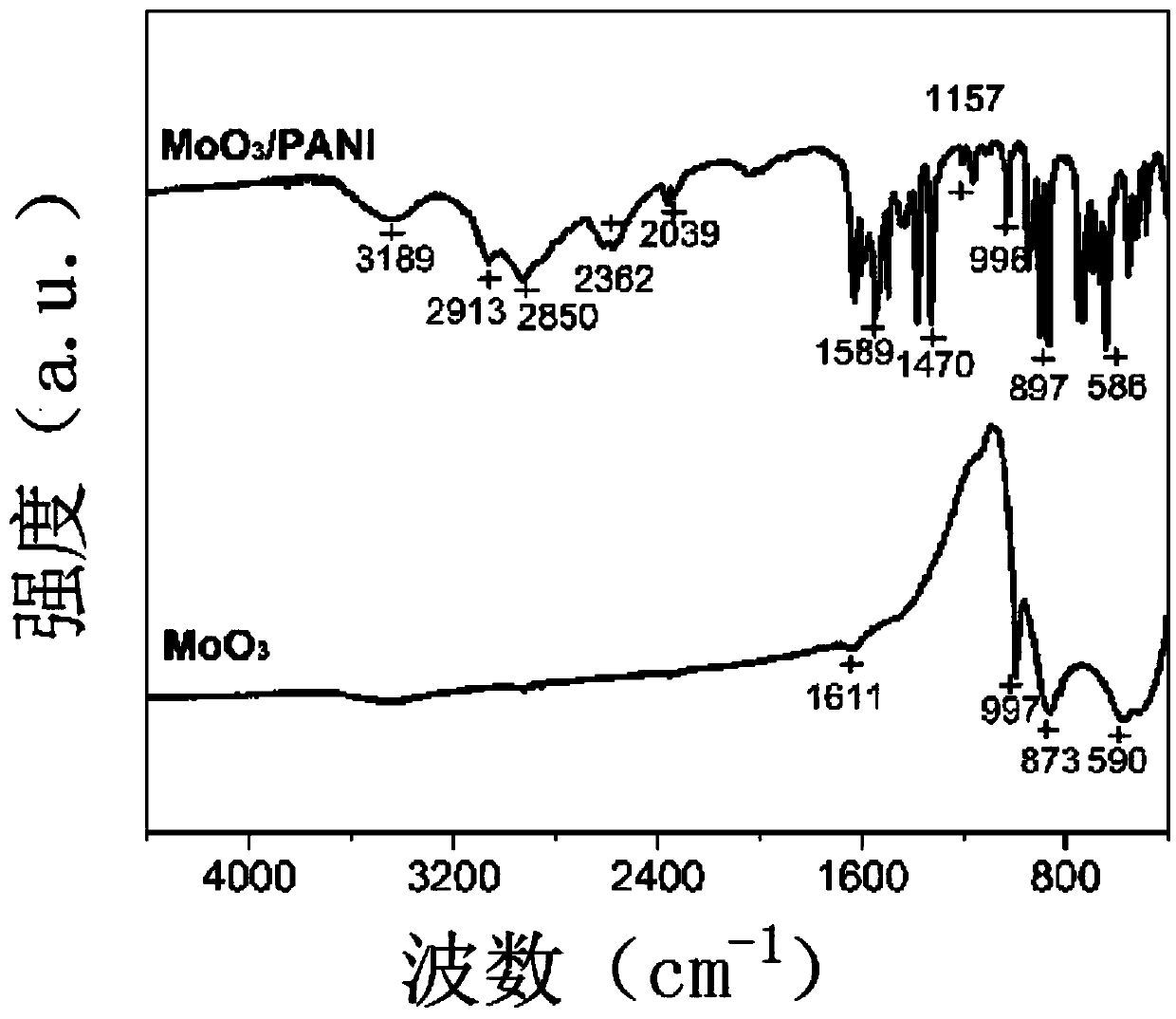

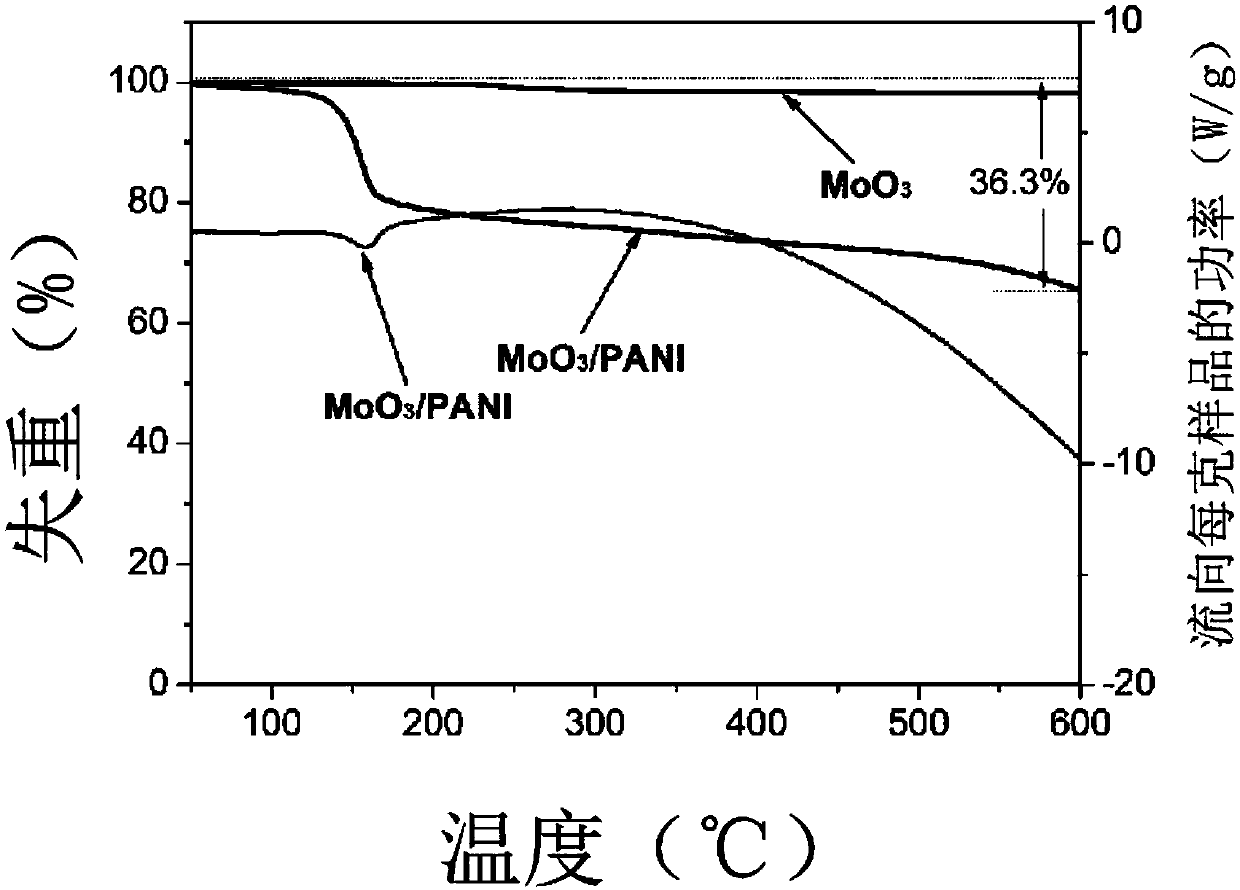

Molybdenum trioxide/polyaniline composite electrode material with layered structure and preparation method thereof

A molybdenum trioxide and composite electrode technology, applied in battery electrodes, structural parts, circuits, etc., can solve the problems of poor conductivity and cycle rate, and achieve good rate performance, low cost of raw materials, and enhanced diffusion ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] S1. Measure 10 mL of CH 3 (CH 2 ) 11 NH 2 (analytical pure) was dissolved in 300 mL of butanol solvent, and after the organic amine was fully dissolved, 1.2 g of molybdenum trioxide (analytical pure) was weighed and added to the above mixed solution, stirred and reacted in a water bath at 60 °C for 48 h, and a white precipitate was formed. Suction filtration and wash the filter cake with butanol solvent, and dry under reduced pressure at 70 °C for 48 h to obtain the molybdenum trioxide organic / inorganic hybrid compound intercalated with organic amine, which is the precursor of organic amine intercalation;

[0028] S2. Measure 0.5 g of the precursor of organic amine intercalation and add 9.6 mL of aniline to 240 mL of propionic acid solvent, N 2 Protected atmosphere, stirred and reacted in a water bath at 80 °C for 96 h, a pale pink precipitate was formed, filtered with suction and washed the filter cake with butanol solvent, and dried under reduced pressure at 50 °C...

Embodiment 2

[0032] S1. Measure 10 mL of CH 3 (CH 2 ) 12 NH 2 (analytical pure) dissolved in 200 mL of propanol solvent, until the organic amine was fully dissolved, weighed 0.63 g of molybdenum trioxide (analytical pure) into the above mixed solution, stirred and reacted in a water bath at 70 °C for 36 h, and a white precipitate was formed. Suction filtration and wash the filter cake with propanol solvent, and dry under reduced pressure at 70 °C for 48 h to obtain the molybdenum trioxide organic / inorganic hybrid compound intercalated with organic amine, which is the precursor of organic amine intercalation;

[0033] S2. Measure 0.5 g of the precursor of organic amine intercalation and add 6.9 mL of aniline to 200 mL of acetic acid solvent, N 2 Protected atmosphere, stirred and reacted in a water bath at 65 °C for 120 h, a pale pink precipitate was formed, filtered with suction and washed the filter cake with propanol solvent, and dried under reduced pressure at 50 °C for 24 h to obtai...

Embodiment 3

[0037] S1. Measure 8 mL of CH 3 (CH 2 )12NH 2 (analytical pure) was dissolved in 200 mL of ethanol solvent, and after the organic amine was fully dissolved, 0.55 g of molybdenum trioxide (analytical pure) was weighed and added to the above mixed solution, stirred and reacted in a water bath at 90 °C for 48 h, a white precipitate was formed, and pumped Filter and wash the filter cake with an ethanol solvent, dry under reduced pressure at 70°C for 48 h to obtain a molybdenum trioxide organic / inorganic hybrid compound intercalated with an organic amine, which is the precursor of the intercalated organic amine;

[0038] S2. Measure 0.5 g of the precursor of organic amine intercalation and add 4.5 mL of aniline to 180 mL of acetic acid solvent, N 2 The atmosphere was protected, stirred and reacted in a water bath at 70 °C for 96 h, a pale pink precipitate was formed, the filter cake was filtered with suction and washed with ethanol solvent, and dried under reduced pressure at 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com