Preparation method and application of biomimetic oxygen reduction electrocatalyst based on metal macrocyclic compound

A technology of macrocyclic compounds and electrocatalysts, applied in circuits, electrical components, battery electrodes, etc., can solve problems such as low efficiency of covalent bond replacement, complicated experimental methods, and damage to the conductivity of carbon materials, and achieve a large specific surface area, conductive Good performance, improve the effect of electron conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

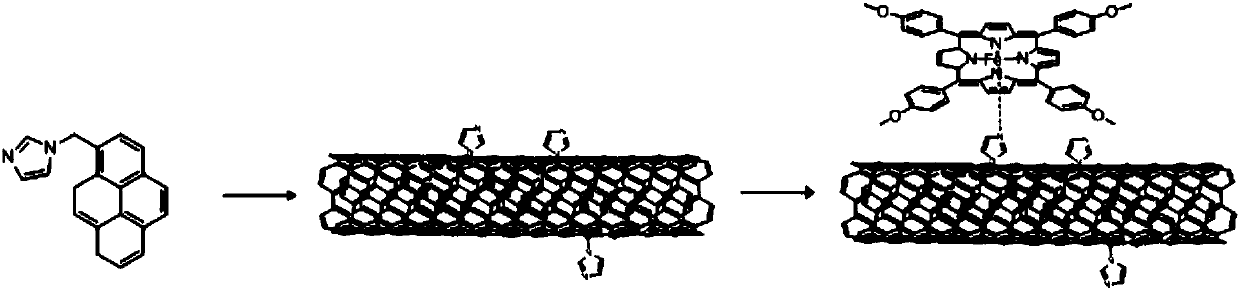

Method used

Image

Examples

Embodiment 1

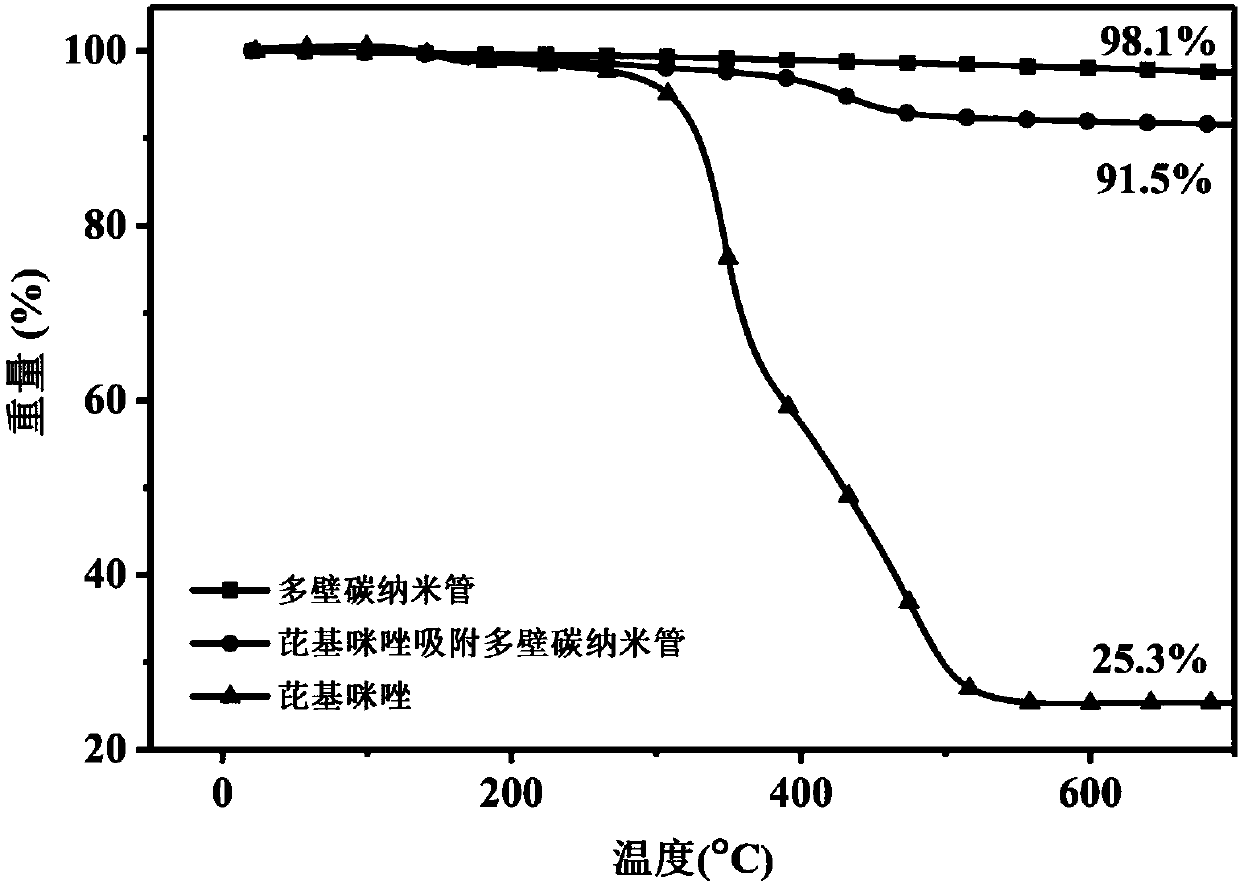

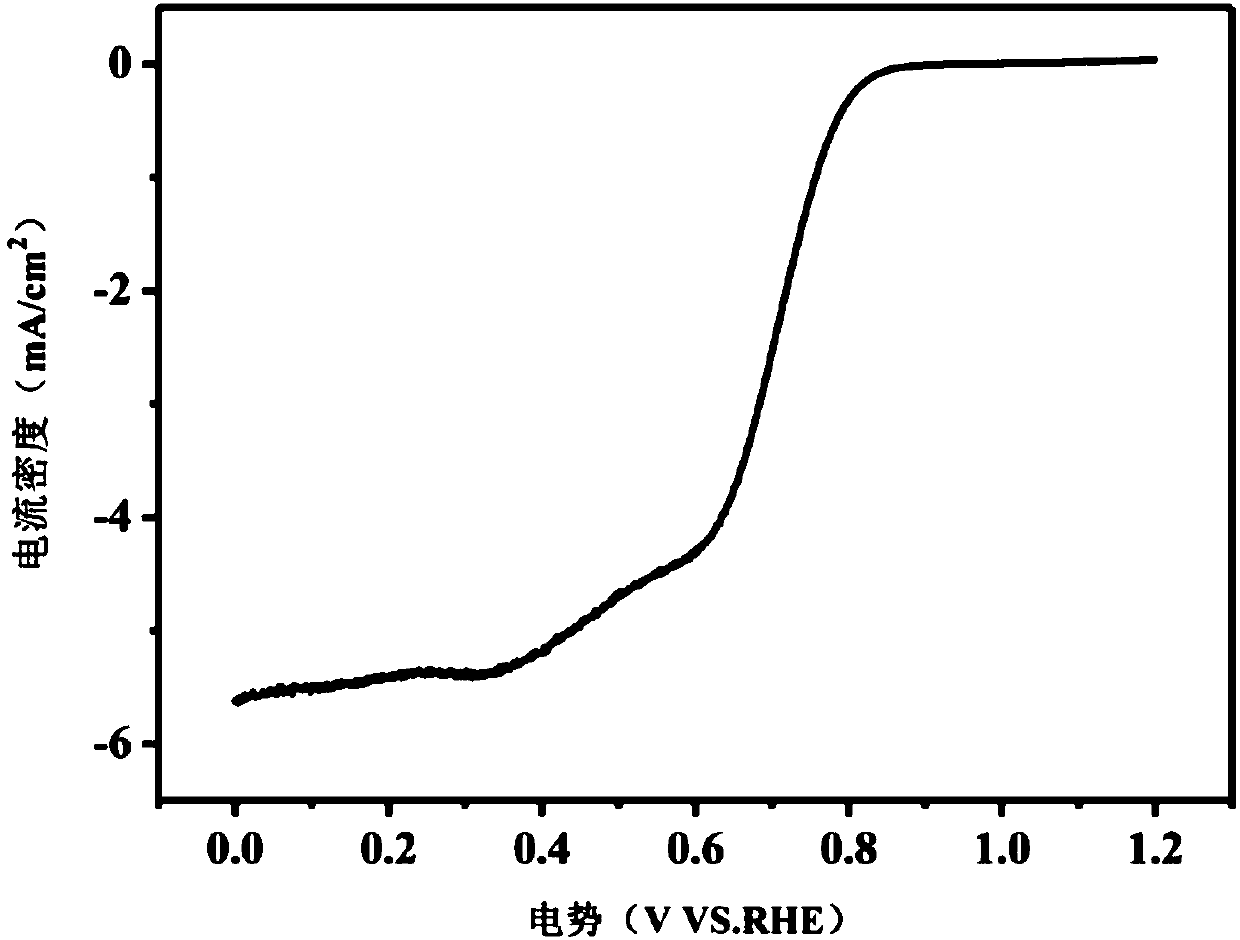

[0025] Disperse 10mg of multi-walled carbon nanotubes and 40mg of compound A (n=1) in 5ml of N,N-dimethylformamide solution, sonicate at 25°C for 30min, stand at -10°C, and filter with suction after 24h , washed with N,N-dimethylformamide until the filtrate was pure and colorless, dried at 65°C, dispersed the obtained black powder solid in 10ml of methanol solution, added 40mg of hematin, and stirred at 25°C under nitrogen for 24h , filtered methanol and washed until the filtrate was colorless, and dried.

Embodiment 2

[0027] Disperse 50 mg of multi-walled carbon nanotubes and 30 mg of compound B (n=2) in 5 ml of tetrahydrofuran solution, ultrasonicate at 25°C for 30 min, stand at -10°C for 24 h, and then filter with suction, wash with tetrahydrofuran until the filtrate is pure and colorless, Dry at ℃, disperse the obtained black powder solid in 10ml of methanol solution, add 40mg of cobalt phthalocyanine, stir at 55℃ under nitrogen for 24h, filter methanol and wash until the filtrate is colorless, and dry. The morphology and performance of the obtained catalyst are similar to those of the sample in Example 1, and it has good overall oxygen reduction performance.

Embodiment 3

[0029] Disperse 20mg of graphene and 100mg of compound C (n=4) in 5ml of cyclohexane solution, ultrasonicate at 25°C for 120min, stand still at 20°C for 48h, then filter with suction, wash with cyclohexane until the filtrate is pure and colorless, at 65°C Dry at ℃, disperse the obtained black powder solid in 10ml of cyclohexane solution, add 40mg of tetramethoxyphenyliron porphyrin, stir at 80℃ under nitrogen for 12h, filter and wash with cyclohexane until the filtrate is colorless, drying. The morphology and performance of the obtained catalyst are similar to those of the sample in Example 1, and it has good overall oxygen reduction performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com