Method for preparing multi-phase photonic Fenton catalyst from city sludge and red brick wastes and product and application

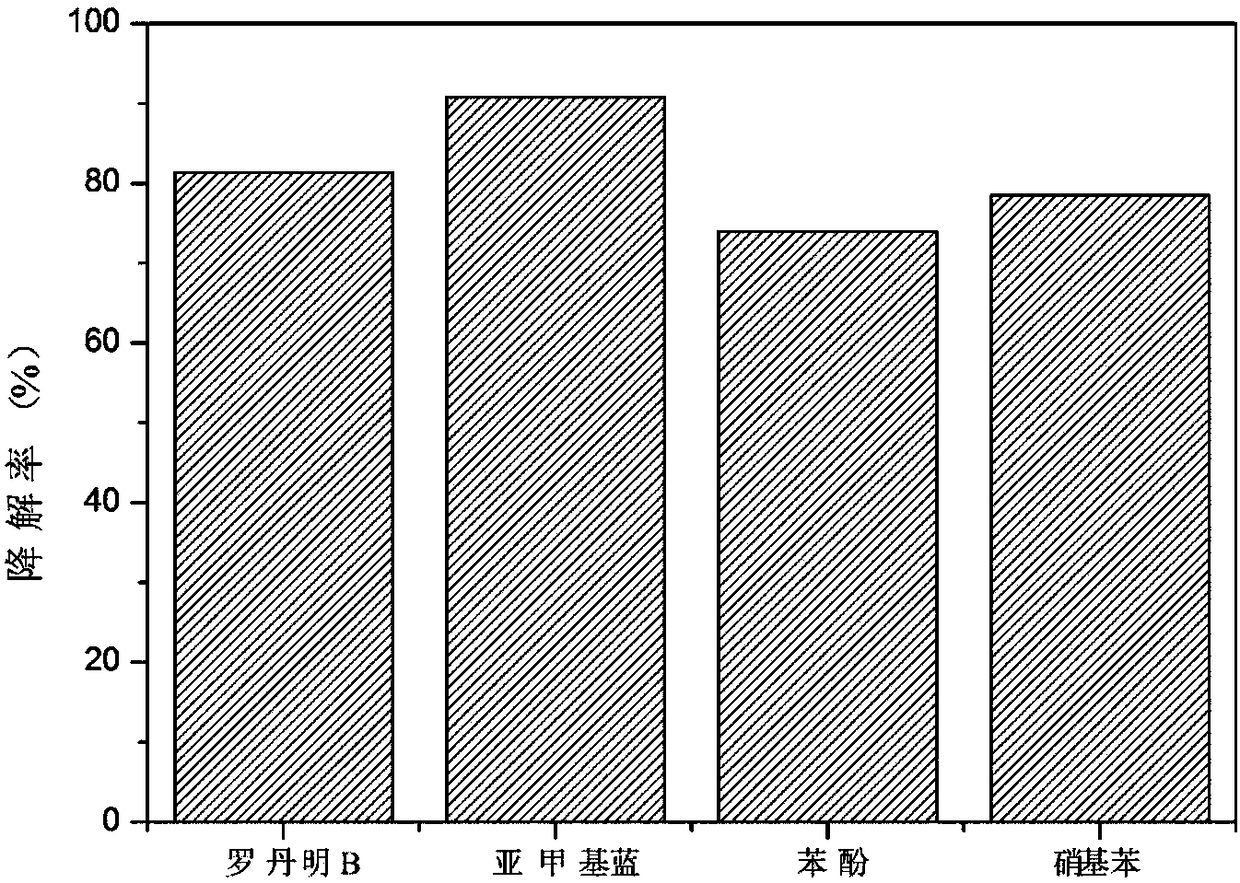

A technology of municipal sludge and catalyst, which is applied in the field of waste resource utilization and environmental catalytic materials, can solve the problems of weak adsorption capacity of pollutants in water, low specific surface area of catalyst, poor visible light response, etc., and achieve easy waste reuse, The effect of low cost and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment is a method for preparing heterogeneous photo-Fenton catalysts from municipal sludge and red brick waste, comprising the following steps:

[0029] Step 1, placing the dewatered sludge and red brick waste at 105°C for 24 hours to obtain dry sludge and dry red brick waste;

[0030] Step 2, the dry red brick waste material obtained in step 1 is pulverized with a mechanical pulverizer at a rotation speed of 2500 rpm / min, and after pulverization, the dry red brick waste material particles are obtained through 60 mesh screening;

[0031] Step 3, mixing 3Kg of dry sludge obtained in step 1 with 2Kg of dry red brick waste particles obtained in step 2, and then grinding with a ball mill at a speed of 15rpm / min, and screening through 300 meshes to obtain mixed particles after grinding;

[0032] Step 4, placing the mixed particles obtained in step 3 in a muffle furnace, and calcining at 950°C, the calcination time is 60min, the heating rate is 10°C / min, and after t...

Embodiment 2

[0036] This embodiment is a method for preparing heterogeneous photo-Fenton catalysts from municipal sludge and red brick waste, comprising the following steps:

[0037] Step 1, placing the dewatered sludge and red brick waste at 100°C for 18 hours to obtain dry sludge and dry red brick waste;

[0038] Step 2, the dry red brick waste material obtained in step 1 is pulverized with a mechanical pulverizer at a rotation speed of 1500 rpm / min, and after pulverization, the dry red brick waste material particles are obtained through 60-mesh screening;

[0039] Step 3, mixing 4Kg of dry sludge obtained in step 1 with 2Kg of dry red brick waste particles obtained in step 2, and then grinding with a ball mill at a speed of 18rpm / min, and screening through 300 meshes to obtain mixed particles after grinding;

[0040] Step 4, placing the mixed particles obtained in step 3 in a muffle furnace, and calcining at 800°C, the calcination time is 30 minutes, the heating rate is 15°C / min, and af...

Embodiment 3

[0044] This embodiment is a method for preparing heterogeneous photo-Fenton catalysts from municipal sludge and red brick waste, comprising the following steps:

[0045] Step 1, placing the dewatered sludge and red brick waste at 95°C for 12 hours to obtain dry sludge and dry red brick waste;

[0046] Step 2, the dry red brick waste material obtained in step 1 is pulverized with a mechanical pulverizer at a rotation speed of 1000 rpm / min, and after pulverization, the dry red brick waste material particles are obtained through 60-mesh screening;

[0047] Step 3, mixing 4Kg of dry sludge obtained in step 1 with 1Kg of dry red brick waste particles obtained in step 2, and then grinding with a ball mill at a speed of 21rpm / min, and screening through 300 meshes to obtain mixed particles after grinding;

[0048]Step 4, placing the mixed particles obtained in step 3 in a muffle furnace, and calcining at 1050° C. for 120 minutes, with a heating rate of 20° C. / min. After the calcinatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com