Hard carbon prepared from biomass waste bagasse as well as preparation method and application of harden carbon

A sugarcane bagasse and biomass technology, applied in the field of energy storage, can solve the problems of performance impact, unstable performance, complex preparation process, etc., and achieve the effects of low cost, high specific capacity and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This example is used to illustrate the biomass hard carbon material of the present invention and its preparation method.

[0030] Present embodiment adopts biomass waste bagasse to prepare the preparation method of hard carbon material, and concrete steps comprise as follows:

[0031] Step 1: Clean the bagasse by ultrasonic, then dry it in a blast drying oven at 60°C, and crush it into powder for later use.

[0032] Step 2: Take 10 g of bagasse powder and 200 g of ball milling beads and place them in a planetary ball mill tank, and ball mill at a speed of 350 r / min for 12 hours to obtain bagasse powder after mechanical ball milling.

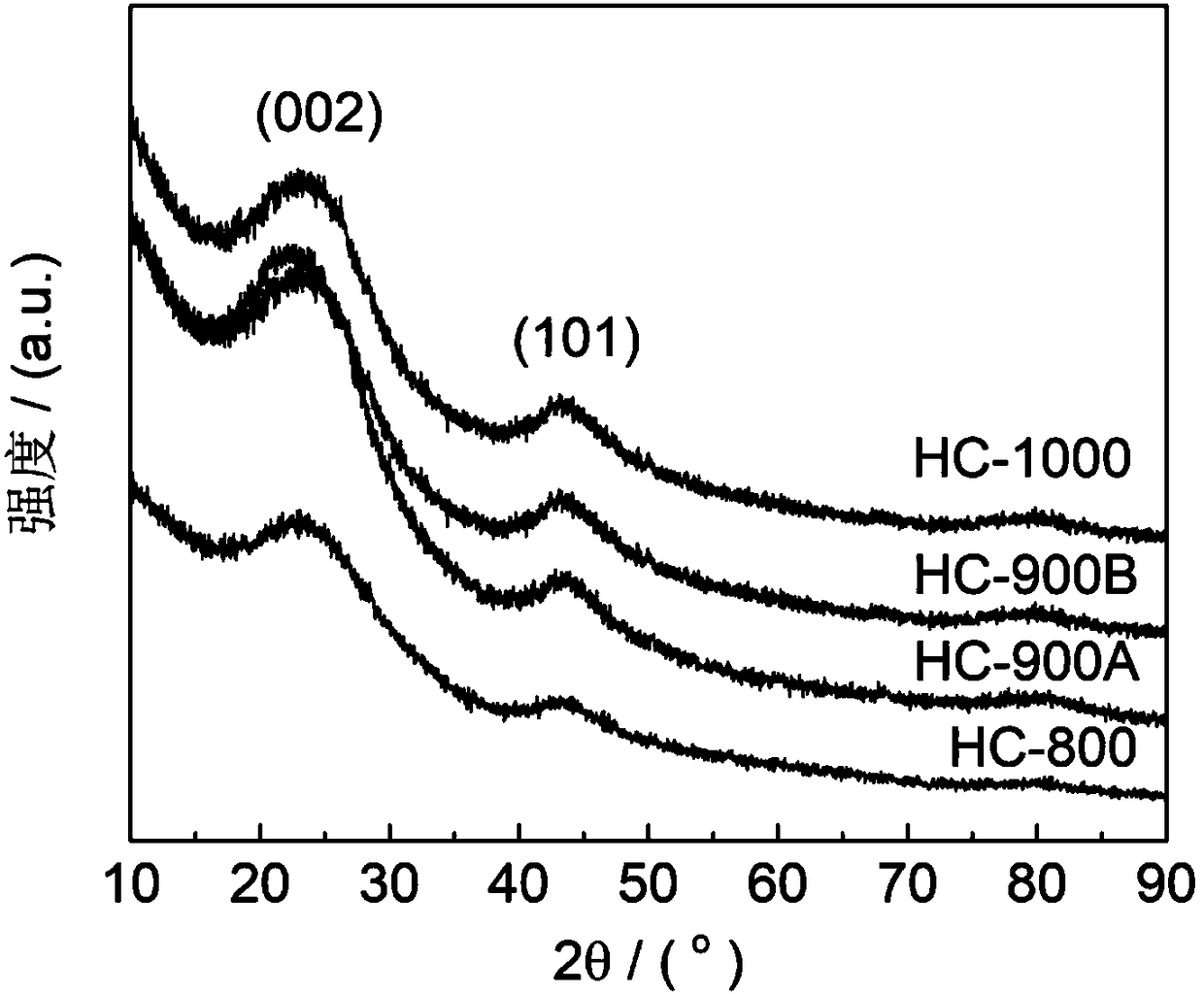

[0033] Step 3: Take 5g of bagasse powder in step 2 and place it in a tube furnace. In an argon flow, heat it up to 800°C at a rate of 5°C / min for heat treatment for 2 hours. After the reaction, cool to room temperature to obtain biomass Hard carbon material, marked HC-800.

Embodiment 2

[0035] This example is to illustrate the biomass hard carbon material of the present invention and its preparation method.

[0036] Present embodiment adopts biomass waste bagasse to prepare the preparation method of hard carbon material, and concrete steps comprise as follows:

[0037] Step 1: Clean the bagasse by ultrasonic, then dry it in a blast drying oven at 60°C, and crush it into powder for later use.

[0038] Step 2: Take 5g of bagasse powder in step 1 and place it in a tube furnace. In an argon flow, heat it up to 900°C at a rate of 5°C / min for heat treatment for 2 hours. After the reaction, cool to room temperature to obtain biomass Hard carbon material, marked HC-900A.

Embodiment 3

[0040] This example is used to illustrate the biomass hard carbon material of the present invention and its preparation method.

[0041] Present embodiment adopts biomass waste bagasse to prepare the preparation method of hard carbon material, and concrete steps comprise as follows:

[0042] Step 1: Clean the bagasse by ultrasonic, then dry it in a blast drying oven at 60°C, and crush it into powder for later use.

[0043] Step 2: Take 10 g of bagasse powder and 150 g of ball milling beads and place them in a planetary ball mill jar, and ball mill for 12 hours at a speed of 400 r / min to obtain bagasse powder after mechanical ball milling.

[0044] Step 3: Take 3 g of bagasse powder in step 2 and place it in a tube furnace, heat it at 900° C. for 2 hours in an argon flow at a heating rate of 3° C. / min, and cool to room temperature after the reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com