Lactic acid bacteria beverage containing mannan-oligosaccharides and preparation method thereof

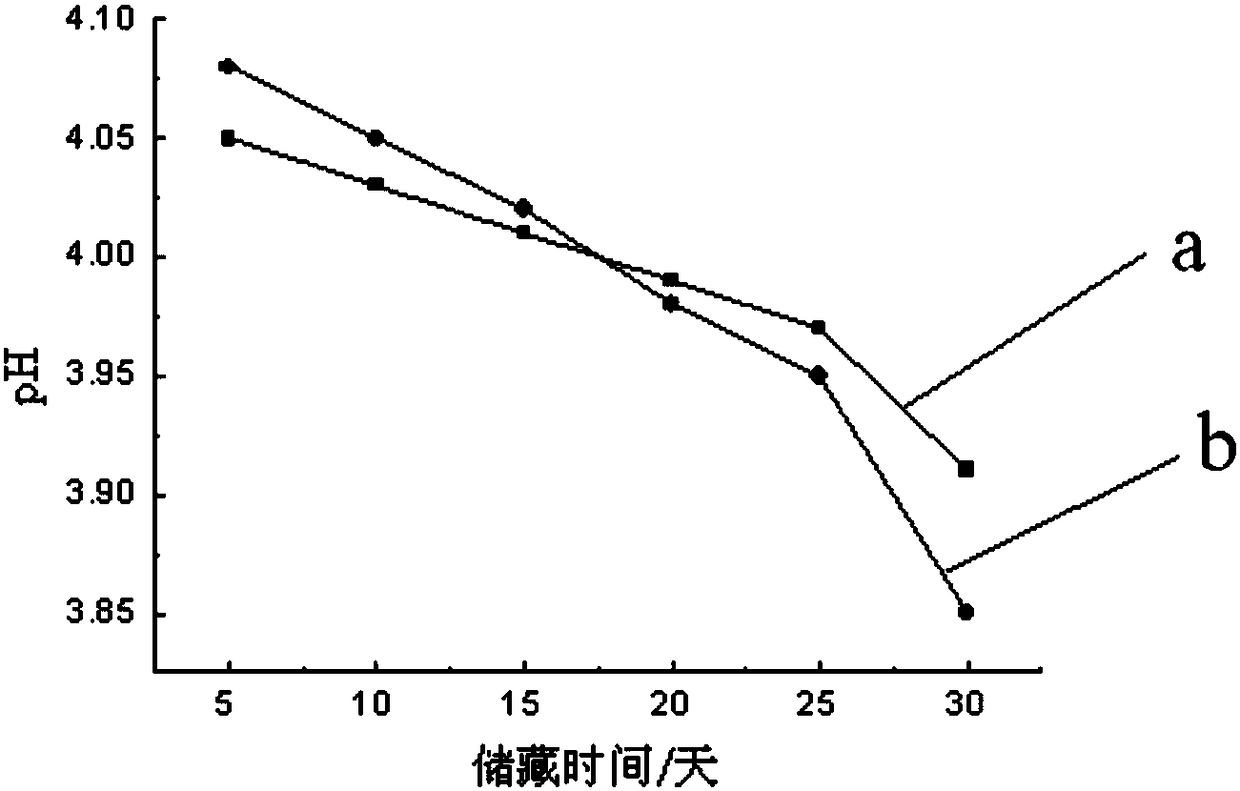

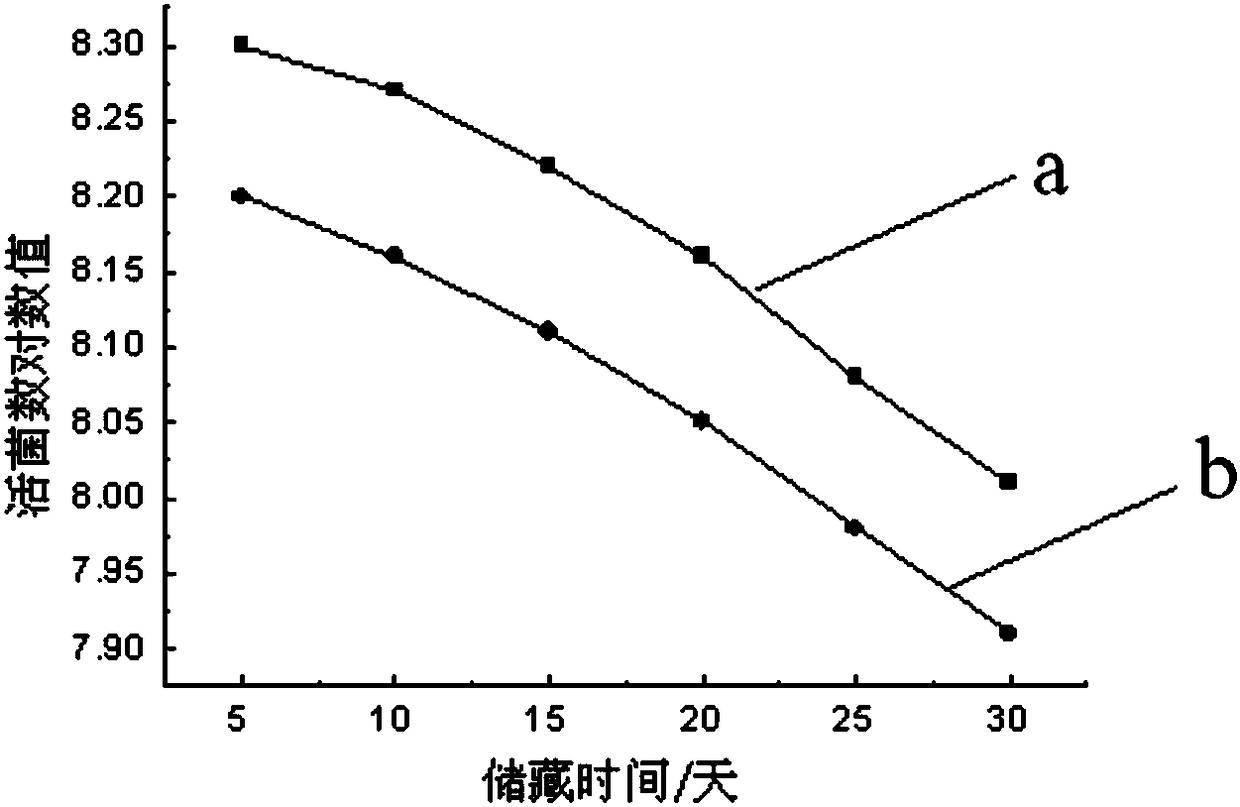

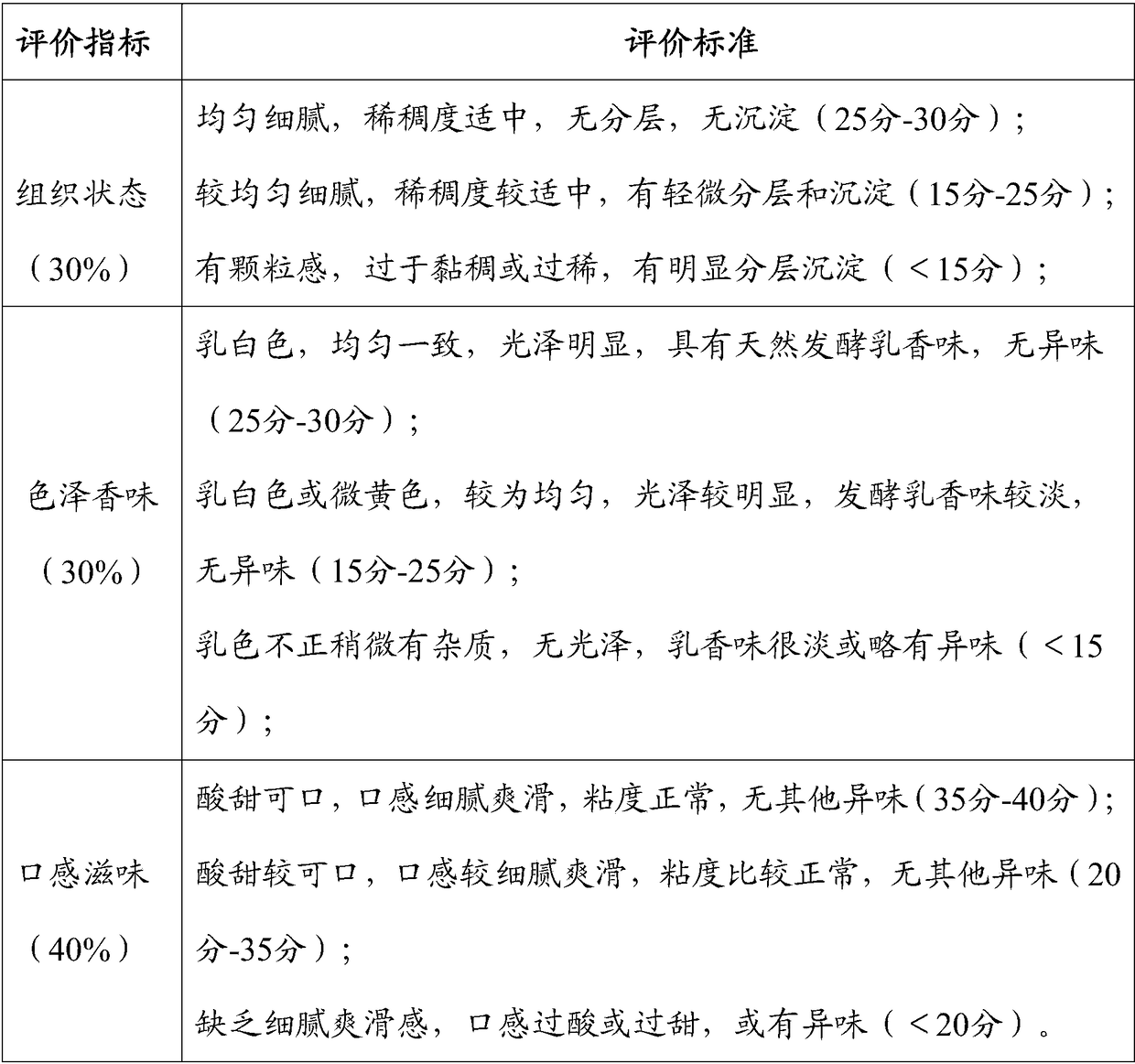

A mannose oligosaccharide and lactic acid bacteria beverage technology, which is applied in the field of dairy product processing, can solve serious problems such as serious decline in the number of viable bacteria, acidification, etc., achieve good tissue status, improve taste and nutrition, and inhibit post-acidification effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of a lactic acid bacteria beverage containing mannose oligosaccharides, comprising the following preparation steps:

[0037] Step 1: Heat 95.5 parts of raw milk to 60°C, add 4 parts of white sugar while stirring, stir for 15 minutes, homogenize at a pressure of 180 bar and a temperature of 65°C, then sterilize at 95°C for 5 minutes, and then cool to 41 ℃, inoculated with 0.03 parts of probiotics, and fermented at 41°C for 9 hours to obtain a fermentation base material with an acidity of 101°T, which was then used for later use; wherein, the mass ratio of Streptococcus thermophilus, Lactobacillus bulgaricus and Lactobacillus acidophilus in the probiotics 1:1:1;

[0038] Step 2, heat 90 parts of water to 60°C, mix 7 parts of stabilizer, 3 parts of white sugar and heated water, sterilize at 85°C for 10 minutes, cool to 25°C to obtain stabilizer sugar water, and set aside; among them, stable The mass ratio of soluble starch, pectin and sodium carboxyme...

Embodiment 2

[0042] Step 1: Heat 96.5 parts of raw milk to 60°C, add 3 parts of white sugar while stirring, stir for 15 minutes, homogenize at a pressure of 200 bar and a temperature of 65°C, then sterilize at 95°C for 5 minutes, and then cool to 41 ℃, inoculated with 0.03 parts of probiotics, and fermented at 41°C for 9 hours to obtain a fermentation base material with an acidity of 101°T, which was then used for later use; wherein, the mass ratio of Streptococcus thermophilus, Lactobacillus bulgaricus and Lactobacillus acidophilus in the probiotics 1:1:1;

[0043] Step 2, heat 90 parts of water to 60°C, mix 7 parts of stabilizer, 3 parts of white sugar and heated water, sterilize at 85°C for 10 minutes, cool to 25°C to obtain stabilizer sugar water, and set aside; among them, stable The mass ratio of soluble starch, pectin and sodium carboxymethyl cellulose in the agent is 1:1:2;

[0044] Step 3, mix 35% fermentation base material and 65% stabilizer sugar water, homogenize at a pressure...

Embodiment 3

[0047]Step 1: Heat 96.5 parts of raw milk to 60°C, add 3 parts of white sugar while stirring, stir for 15 minutes, homogenize at a pressure of 200 bar and a temperature of 65°C, then sterilize at 95°C for 5 minutes, and then cool to 41 ℃, inoculated with 0.03 parts of probiotics, and fermented at 41°C for 9 hours to obtain a fermentation base material with an acidity of 101°T, which was then used for later use; wherein, the mass ratio of Streptococcus thermophilus, Lactobacillus bulgaricus and Lactobacillus acidophilus in the probiotics 1:1:1;

[0048] Step 2, heat 90 parts of water to 60°C, mix 7 parts of stabilizer, 3 parts of white sugar and heated water, sterilize at 85°C for 10 minutes, cool to 25°C to obtain stabilizer sugar water, and set aside; among them, stable The mass ratio of soluble starch, konjac powder, sodium carboxymethylcellulose in the agent is 1:1:2;

[0049] Step 3, mix 40% fermentation base material and 60% stabilizer sugar water, homogenize at a pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com