Mask sheet comprising silk produced by golden silkworm cocoon and mask using same

A sheet and raw silk technology, applied in the production of silk fibers, packaging of toiletries, and the use of carriers to introduce foreign genetic materials, etc., can solve the problems of low content of active substances, high prices, etc., achieve low skin irritation and improve moisturizing power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1: the preparation of the silk precursor produced by golden silkworm

[0055] Using the transgenic golden silkworm described in Korean Patent No. 10-1570784, specifically, using the golden silkworm transformed with a recombinant expression vector comprising a gene construct operably linked to There are marker gene regulated promoters, a marker gene, a silk protein promoter from silkworms, and a yellow fluorescent gene from siphonophores. The above-mentioned silk raw silk can be produced through the cocoon refining process as described below. Specifically, after the cocoons are shredded, 0.3% (w / v) of sodium oleate and 0.2% (w / v) of sodium carbonate are mixed at a bath ratio (the ratio of silkworm cocoons and refining solution) of 1:25. In an aqueous solution, the silkworm cocoons were treated at 100°C for one hour for refining, washed five times with hot water and distilled water, dried in an oven at 105°C, and finally produced silk precursors of golden sil...

Embodiment 2

[0056] Example 2: Manufacture of a sheet for facial masks comprising silk precursors produced by golden silkworms

[0057] 2-1: Manufacture of non-woven fabric

[0058] The fiber mixed with the silk raw silk which is the refined silk produced in the above-mentioned Example 1 is formed into a web (Web) through a carding process, and then water punching or needle punching (Needle punching) is sequentially performed , Manufactured a composite non-woven fabric for mask sheet.

manufacture example 1-2

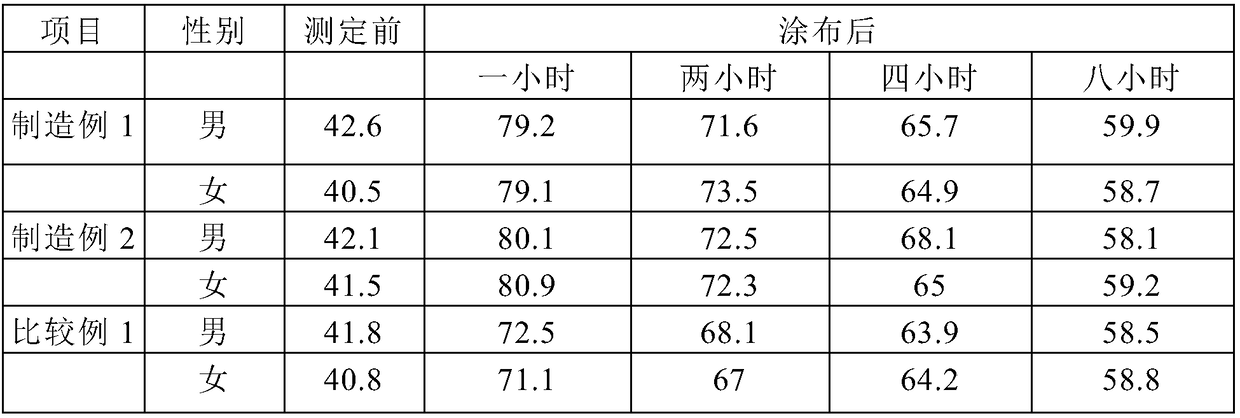

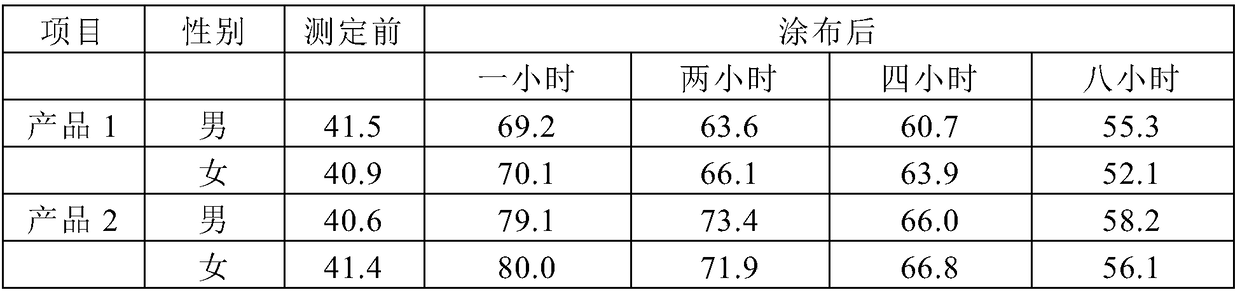

[0059] 2-2: Production of non-woven fabrics using golden silkworm silk raw silk, tencel and pure cotton (manufacturing example 1-2 and comparative example 1-2)

[0060] Production examples 1-2 and comparative examples 1-2 described below were produced using the raw silk of golden silkworm, the raw silk of tencel, and pure cotton produced in the above-mentioned Example 1.

[0061] 1) Manufacture example 1 - set the blending ratio of golden silkworm silk precursor and tencel precursor silk to 5:5 for mixing;

[0062] 2) Manufacturing example 2 - set the blending ratio of the silk precursor of golden silkworm and tencel precursor to 7:3 for mixing;

[0063] 3) Comparative example 1 - the blending ratio of pure cotton and Tencel raw silk is set to 5:5 for mixing;

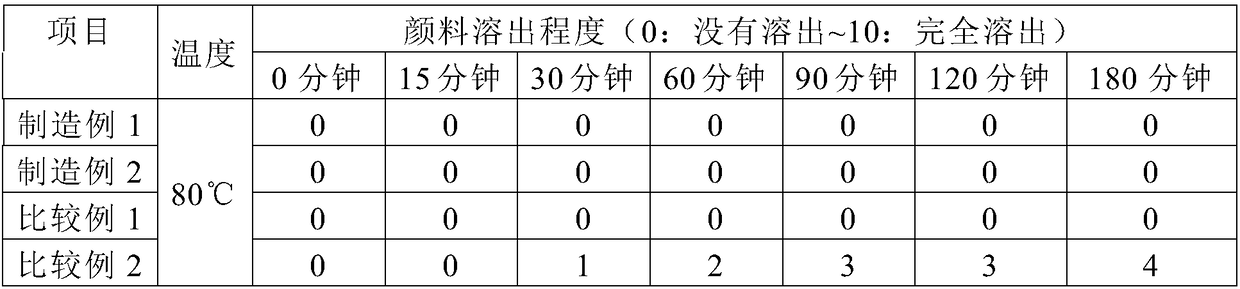

[0064] 4) Comparative Example 2 - The blending ratio of pure cotton and tencel raw silk is set to 5:5, and then mixed with a colorant (C.I.SOLVENT YELLOW82 of Hyundai Chemical, CAS No.: 12227-67-7) coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com