Method for preparing silver nano-wire and graphene-based calcium alginate composite conductive fibers

A composite conductive and silver nanowire technology, which is applied in fiber treatment, alginate artificial filament, wet spinning, etc., can solve the problems of low conductivity and processability, complex conductive composite fiber technology, etc., and achieve good results. The effect of universality, good electrical conductivity and processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

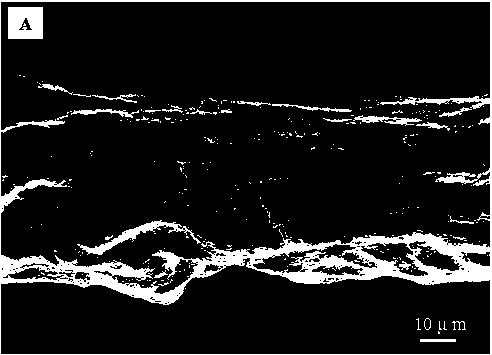

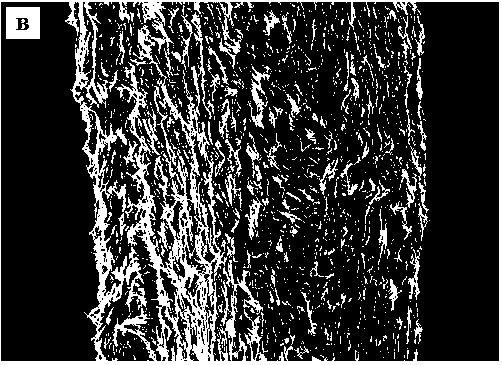

[0027] First, prepare 0.5 mg / mL silver nanowire alcohol solution and graphene aqueous solution; secondly, use 1.5% sodium alginate and 30% calcium chloride alcohol solution as the preparation of calcium alginate precursor, using Double syringe pumps injected sodium alginate into the calcium chloride alcohol solution at an injection rate of 5mL / min to obtain calcium alginate microfibers; the calcium alginate microfibers prepared above were immersed in dodecane containing 3% mass concentration Sodium benzene sulfonate solution for 2 hours, so that the fiber surface is positively charged; again, the fiber prepared in the foregoing is added dropwise to the prepared silver nanowire alcohol solution under stirring conditions, and the alcohol of the silver nanowire After the solution is added dropwise, continue to stir for 0.2 hours, then add the aqueous solution of graphene dropwise under stirring conditions, and continue to stir for 0.2 hours; finally, the product can be obtained by...

Embodiment 2

[0029] First, prepare 1.0 mg / mL silver nanowire alcohol solution and 0.5 mg / mL graphene aqueous solution; secondly, use 2.5% sodium alginate and 30% calcium chloride alcohol solution as the preparation calcium alginate For the precursor, sodium alginate was injected into the calcium chloride alcohol solution at an injection rate of 5 mL / min using a double syringe pump to obtain calcium alginate microfibers; the calcium alginate microfibers prepared above were immersed in a solution containing 3% Sodium dodecylbenzenesulfonate solution for 2 hours, so that the surface of the fiber is positively charged; again, the fiber prepared in the foregoing is added dropwise to the prepared silver nanowire alcohol solution under the condition of stirring, and the silver After the alcohol solution of the nanowires is added dropwise, continue to stir for 0.2 hours, then add the aqueous solution of graphene dropwise under stirring conditions, and continue to stir for 0.2 hours; finally, the pr...

Embodiment 3

[0031] First, prepare 1.0 mg / mL silver nanowire alcohol solution and 0.5 mg / mL graphene aqueous solution; secondly, use 2.5% sodium alginate and 50% calcium chloride alcohol solution as the preparation calcium alginate Precursor, inject sodium alginate into the calcium chloride alcohol solution at an injection rate of 10mL / min using a double syringe pump to obtain calcium alginate microfibers; immerse the calcium alginate microfibers prepared above into cetyltrimethylammonium bromide solution for 3 hours, so that the surface of the fiber is positively charged; again, the fiber prepared in the foregoing is added dropwise to the prepared silver nanowire alcohol solution under stirring conditions , after the alcohol solution of silver nanowires is added dropwise, continue to stir for 0.5 hours, then add the aqueous solution of graphene dropwise under the condition of stirring, and continue to stir for 0.5 hours; finally, the product can be obtained after centrifugation and washing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com