Colored photosensitive resin composition, color filter and image display device manufactured using the same

A technology of photosensitive resin and composition, applied in instruments, optics, optical components, etc., can solve the problems of unfavorable brightness and reliability, and achieve the effects of high reliability and contrast characteristics, high contrast characteristics and excellent sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0161] Add 30 g of methanol to 2 g of dodecylpyridinium chloride, and slowly drop into the completely dissolved solution to dissolve 6 g of phosphotungstic acid hydrate (Aldrich, P4006) in Solution in 25g of water. After the dropwise addition, the precipitate was stirred at 25 to 50°C for 4 hours, and the precipitate was filtered and washed with water. After filtration, it dried in a 50 degreeC vacuum oven for 12 hours, and obtained 8.5 g of following chemical formula A-1. (Synthesis with reference to Eur.J.Inorg.Chem.2014, 21-35.)

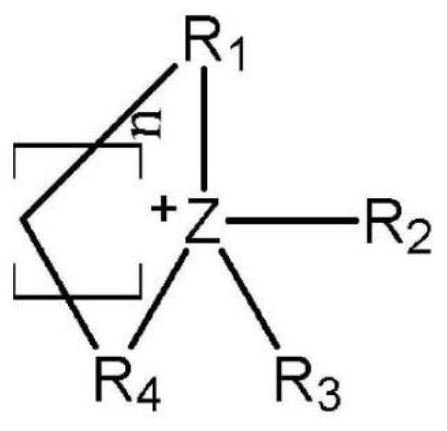

[0162] [Chemical formula A-1]

[0163]

Synthetic example 2

[0165] Using Tetrapropylammonium Hydroxide (TCI, Product No. T0171) instead of dodecylpyridinium chloride, 7.3 g of Chemical Formula A-2 was obtained in the same manner as in Synthesis Example 1.

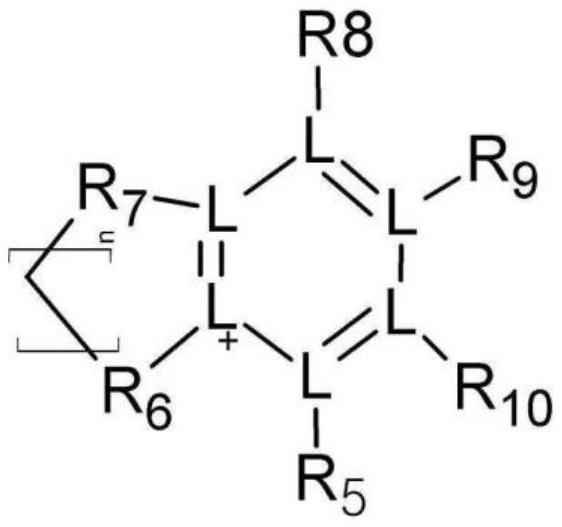

[0166] [Chemical formula A-2]

[0167]

Synthetic example 3

[0168] Synthesis Example 3: Synthesis of Binder Resin (B)

[0169]Add 100 g of propylene glycol monomethyl ether acetate and 100 g of propylene glycol monomethyl ether into a flask equipped with a stirrer, a thermometer, a reflux condenser, a dropping funnel, and a nitrogen introduction pipe, and change the atmosphere in the flask from air to nitrogen. 8.2 g of azobisisobutyronitrile, 3.1 g of monomethacrylate with a tricyclodecane skeleton (FA-513M manufactured by Hitachi Chemical Co., Ltd.), 55.2 g of 2-ethylhexyl acrylate, and 4-methyl 5.9 g of styrene, 85.2 g of glycidyl methacrylate, and 6.0 g of n-dodecanethiol. Then, the temperature of the reaction liquid was raised to 80° C. while stirring, and the reaction was carried out for 4 hours.

[0170] The temperature of the reaction solution was lowered to normal temperature, and the atmosphere of the flask was replaced with air from nitrogen, then 0.2 g of triethylamine, 0.1 g of 4-methoxyphenol, 43.2 g of acrylic acid an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com