OLED panel, manufacturing method therefor, and display device

A manufacturing method and panel technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as complex process, low display brightness, large square resistance of transparent cathode, etc., to simplify process conditions and simplify manufacturing process , the effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

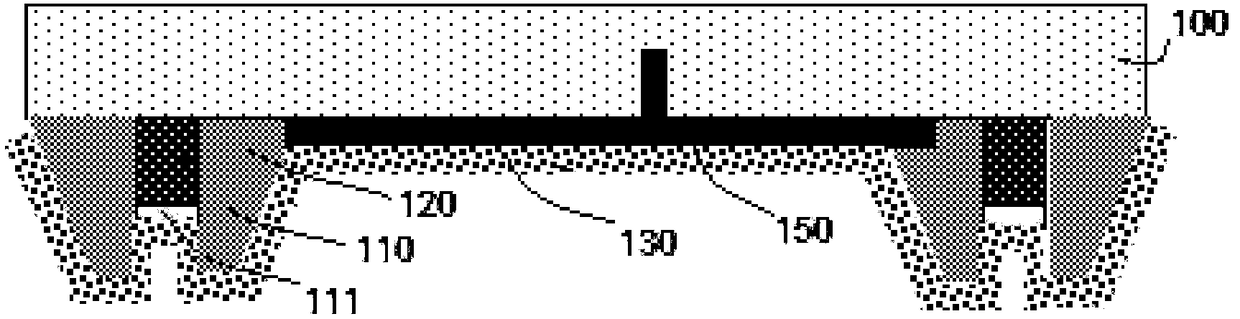

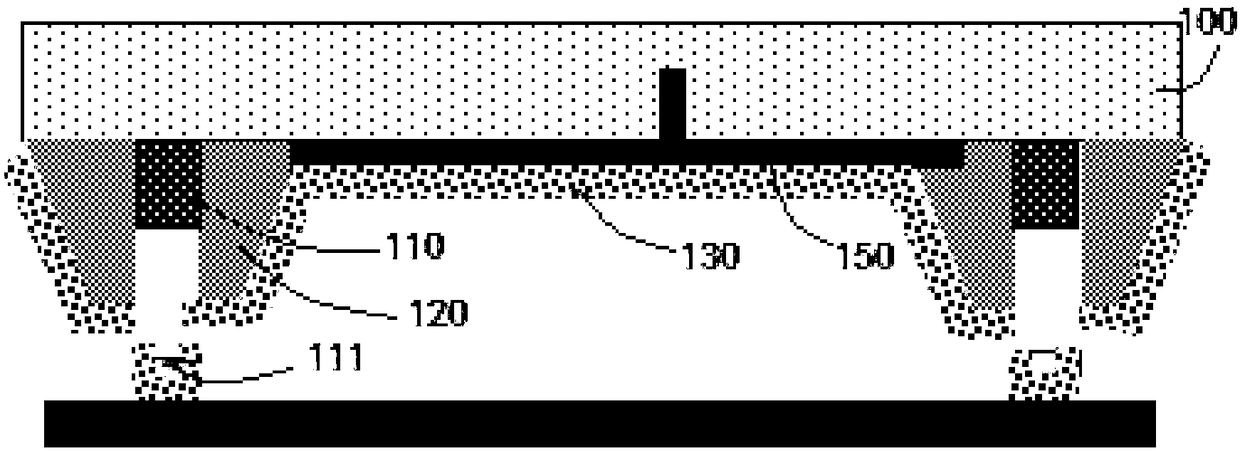

[0031] The present invention will be further described below with reference to the accompanying drawings and exemplary embodiments, wherein the same reference numerals in the accompanying drawings all refer to the same components. Also, detailed descriptions of known arts will be omitted if they are unnecessary to illustrate the features of the present invention.

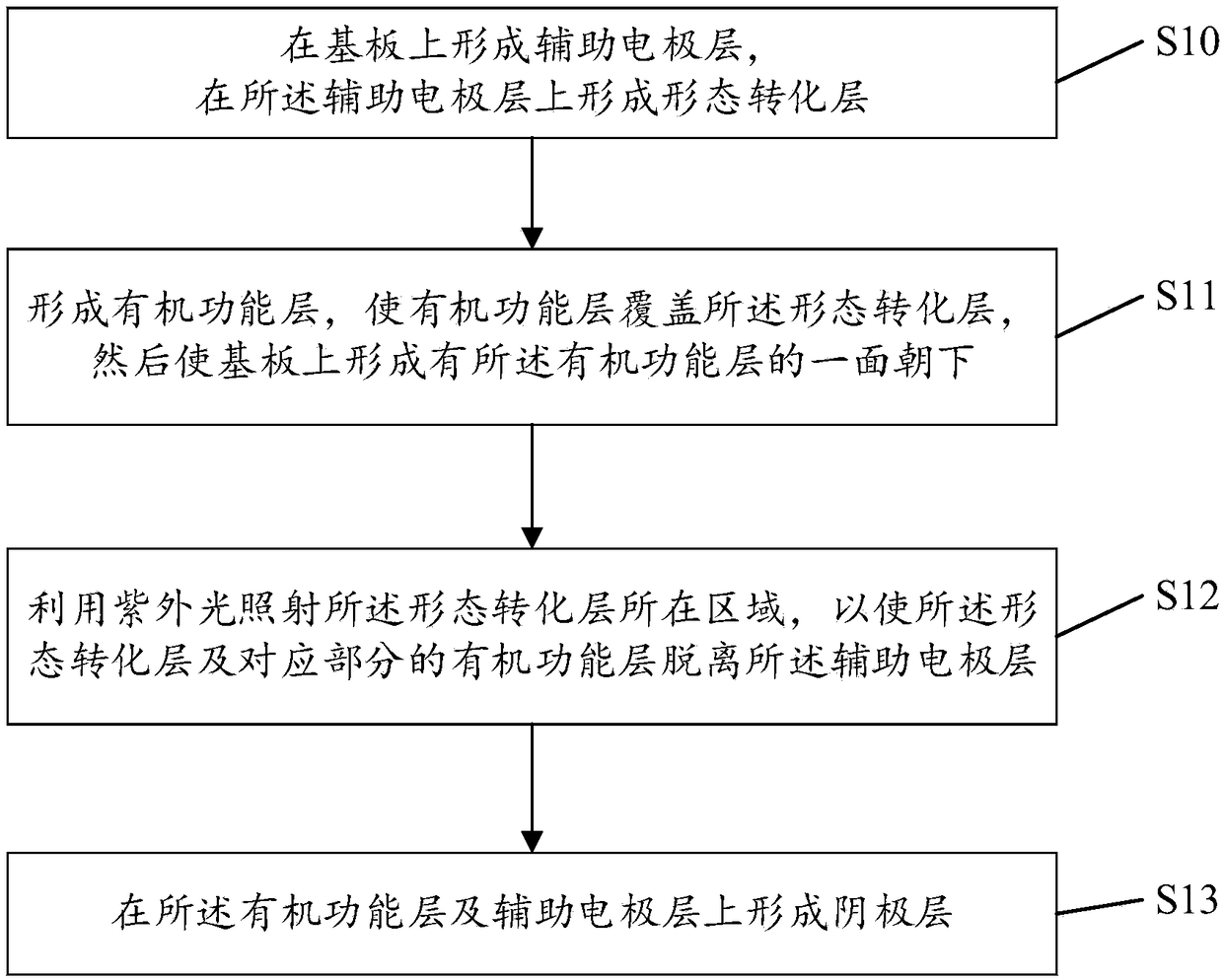

[0032] The present invention provides a method for manufacturing an OLED panel, the flow diagram of which is shown in Figure 1, and the specific steps are as follows:

[0033] S10, forming an auxiliary electrode layer on the substrate, and forming a morphology conversion layer on the auxiliary electrode layer;

[0034] Specifically, the auxiliary electrode layer can be deposited by evaporation, sputtering, or inkjet printing, and the morphology conversion layer can be fixed on the auxiliary electrode layer by inkjet printing, evaporation, etc., so that the morphology conversion layer covers the auxiliary electrode l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com