Barbary wolfberry fruit vinegar beverage and preparation method thereof

A technology of vinegar beverage and wolfberry, which is applied in the preparation of vinegar, food ingredients containing natural extracts, and the function of food ingredients, etc. It can solve the problems of poor taste and achieve the effect of pure taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

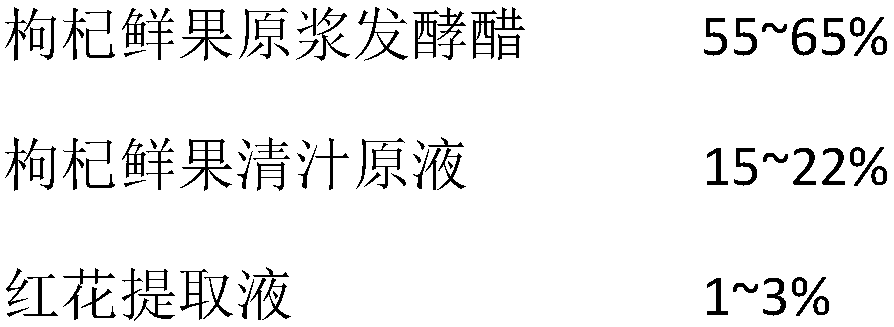

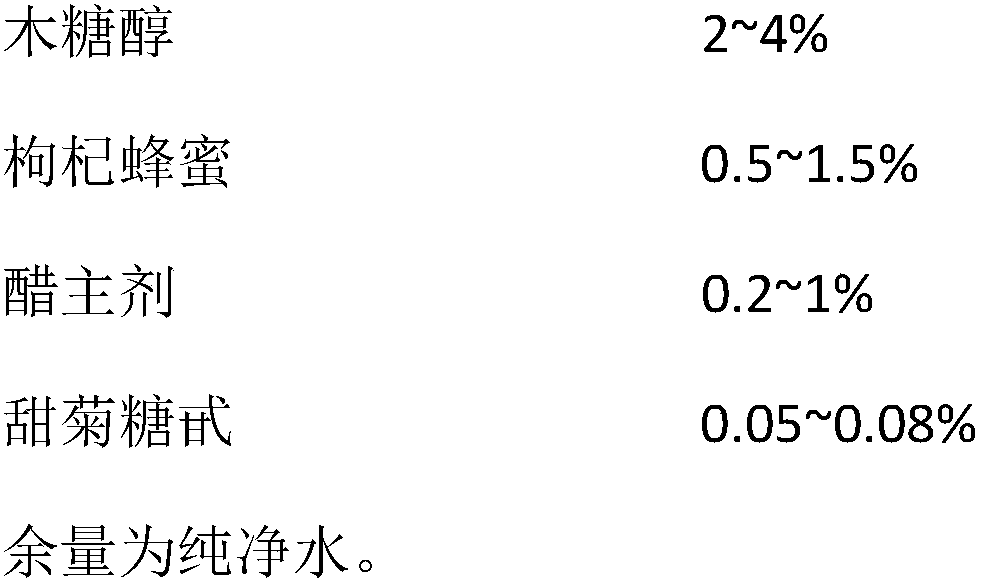

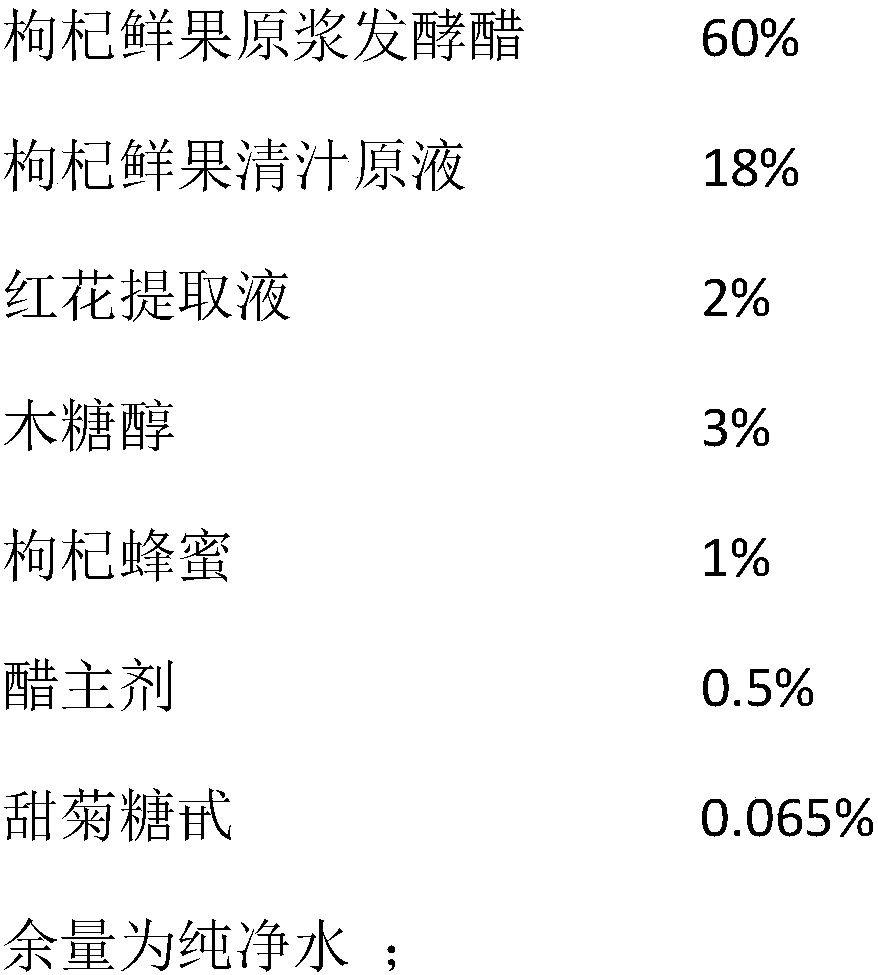

Examples

preparation example Construction

[0026] The second aspect of the present invention protects the preparation method of wolfberry vinegar beverage described in the first aspect, comprising the following steps:

[0027] S1. Preparation of fermented wolfberry puree vinegar

[0028] S11. Beating: Sterilize the fresh wolfberry fruit with 100ppm sodium hypochlorite aqueous solution, beat after cleaning, and add 50-80ppm-SO4 to the mash after beating 2 ;

[0029] S12. Decomposition and enzyme inactivation: add the substance obtained in step S11 into an enzymatic hydrolysis tank, put in pectinase for decomposition, heat up to 90-98°C, keep warm for 8-12min, and then cool to 20-25°C to obtain the substance A;

[0030] S13. Fermentation and filtration: adjust the acidity and sugar content of substance A, and then carry out alcoholic fermentation and filtration; The filter agent is pumped into the filter press for filtration to obtain clear vinegar, and finally the clear vinegar is heated to 80-85°C by steam and kept ...

Embodiment 1

[0051] S1. Preparation of fermented wolfberry puree vinegar

[0052] S11. Beating: Sterilize the fresh wolfberry fruit with 100ppm sodium hypochlorite aqueous solution for 10 minutes, and wash it by air bubbles and spraying in sequence until the surface of the fresh wolfberry fruit is clean and free of dirt, then beat, and add 50ppm-SO4 to the mash after beating 2 ;

[0053] S12. Decomposition and deactivation: add the substance obtained in step S11 into the enzymolysis tank, and activate pectinase (the amount of pectinase added is 0.02% of the volume of the substance obtained in step S11) with distilled water for 30 minutes and then add enzymolysis In the tank, the amount of distilled water is 10 times the amount of pectinase; the temperature is raised to 37°C and kept at a constant temperature for 1 hour, and continuously stirred to accelerate the decomposition; the temperature is then raised to 95°C, kept for 10 minutes, and cooled to 20°C to obtain substance A ;

[0054]...

Embodiment 2

[0064] S1. Preparation of fermented wolfberry puree vinegar

[0065] S11. Beating: Sterilize the fresh wolfberry fruit with 100ppm sodium hypochlorite aqueous solution for 12 minutes, and wash it by air bubbles and spraying in sequence until the surface of the fresh wolfberry fruit is clean and free of dirt, then beat, and add 65ppm-SO4 to the mash after beating 2 ;

[0066] S12. Decomposition and deactivation: add the substance obtained in step S11 into the enzymolysis tank, and activate pectinase (the amount of pectinase added is 0.03% of the volume of the substance obtained in step S11) with distilled water for 30 minutes and then add enzymolysis In the tank, the amount of distilled water is 10 times the amount of pectinase; the temperature is raised to 37°C and kept at a constant temperature for 1 hour, and continuously stirred to accelerate the decomposition; the temperature is then raised to 95°C, kept for 8 minutes, and cooled to 23°C to obtain substance A ;

[0067] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com