Preparation method for modified zeolite used for synchronously deeply processing nitrogen and phosphorus

A modified zeolite and advanced treatment technology, which is applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of no removal of nitrate nitrogen and phosphate, and achieve the purpose of improving adsorption capacity and expanding The effect of using a wide range of capabilities and resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

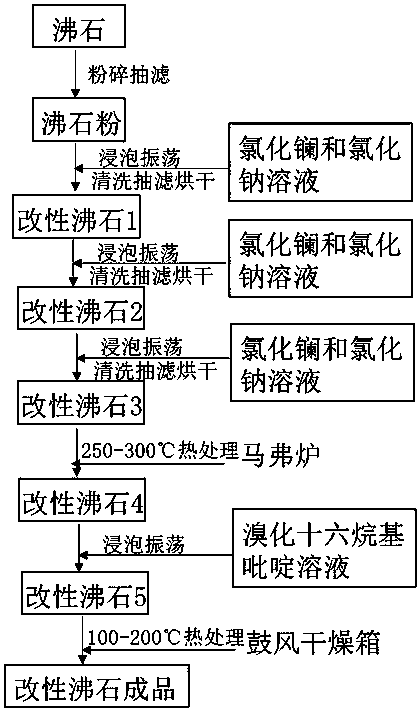

[0026] Specific embodiment 1: This embodiment records a method for preparing a modified zeolite for synchronous advanced treatment of nitrogen and phosphorus. The method includes the following steps:

[0027] Step 1: Prepare the mixed solution A of zeolite and lanthanum chloride and sodium chloride, pulverize the zeolite into powder, and filter and wash with a vacuum pump. The solvent used for washing is water, wherein the mixed solution A of lanthanum chloride and sodium chloride The mass ratio of lanthanum chloride and sodium chloride in the medium is 50:1;

[0028] Step 2: Under alkaline conditions, immerse and shake the zeolite treated in Step 1 in a mixed solution A of lanthanum chloride and sodium chloride;

[0029] Step 3: Take out the zeolite, wash it, filter it with suction and dry it. The drying temperature is 105°C and the drying time is 1 h;

[0030] Step 4: Prepare a mixed solution B of lanthanum chloride and sodium chloride. Under alkaline conditions, put the ze...

specific Embodiment approach 2

[0036] Specific embodiment two: the preparation method of a kind of modified zeolite that is used for the synchronous deep treatment of nitrogen and phosphorus described in specific embodiment one, in step one, the mixed solution A concentration of described lanthanum chloride and sodium chloride is 5g / L.

specific Embodiment approach 3

[0037] Specific embodiment three: the preparation method of a kind of modified zeolite that is used for the synchronous advanced treatment of nitrogen and phosphorus described in specific embodiment one, in step 2, described alkaline condition is pH value=9~11, by NaOH and NaCO 3 Co-adjustment; the soaking temperature is 10-20°C, the soaking time is 12 hours, the rotating speed of the oscillation is 150rpm, and the ratio of zeolite to the mixed solution A of lanthanum chloride and sodium chloride is 1g:50mL.

[0038] Specific embodiment four: the preparation method of a kind of modified zeolite that is used for the synchronous advanced treatment of nitrogen and phosphorus described in specific embodiment one, in step four, the mixed solution B concentration of described lanthanum chloride and sodium chloride is 10g / L.

[0039] Specific embodiment five: a kind of preparation method of the modified zeolite that is used for the synchronous advanced treatment of nitrogen and pho...

PUM

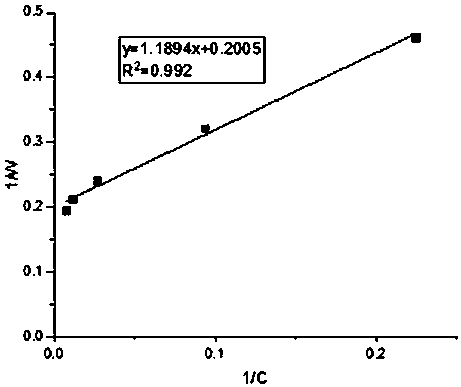

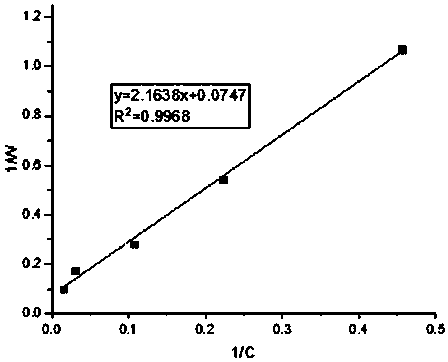

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com