Disinfectant formula based on hydrogen peroxide activation system and application of disinfectant formula

An activation system, hydrogen peroxide technology, applied in the direction of disinfectants, applications, chemical instruments and methods, etc., can solve the problems of limited application of biochemical warfare agents, poor disinfection performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

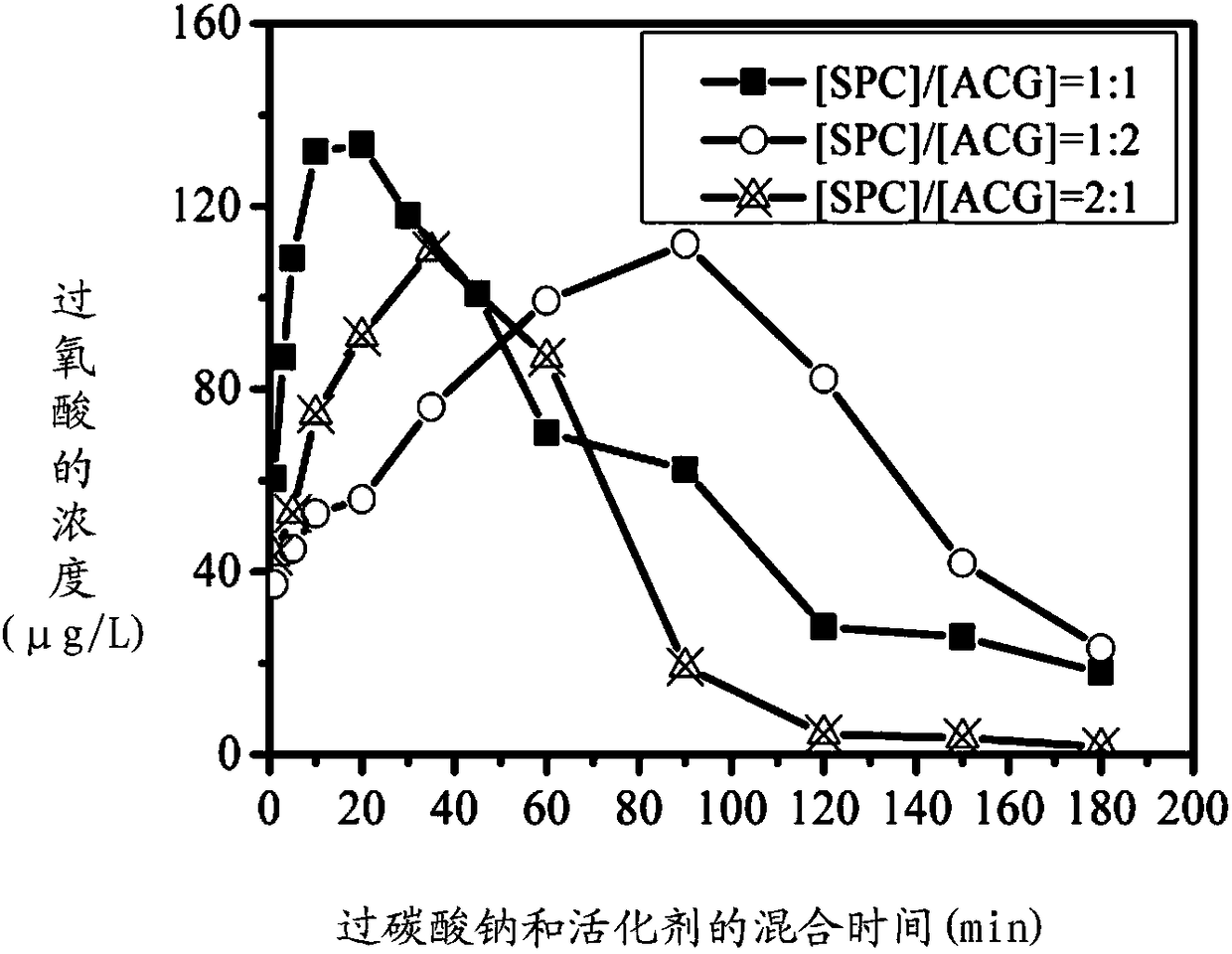

[0046] Components: by mass fraction, sodium percarbonate 0.5%, acetylguanidine 0.125%, add water to 100%.

[0047] Pipette 50mL of the prepared disinfectant into a 100mL three-necked round-bottomed flask, stir at a medium speed for 30min, then transfer 250μL of poison (Viex or Soman) using a micro-injector, and take out 2mL of the disinfectant in 2mL after reacting for 30min. In the extractant (petroleum ether or dichloromethane), shake and shake well, take the extract for toxicant residue analysis, the sample is analyzed by chromatography HP6890-FID. The result is that the disinfection efficiency of Viex and Soman can reach more than 99% within 30 minutes.

Embodiment 2

[0049] Components: by mass fraction, sodium percarbonate 2%, acetylguanidine 2%, synergist 1.2%, add water to 100%.

[0050] Pipette 50mL of the prepared disinfectant into a 100mL three-necked round-bottomed flask, stir rapidly for 30min, then transfer 250μL of poison (mustard gas or Viex) using a micro-injector, react for 5min, take out 1mL of disinfectant and extract it in 2mL Shake well in the solvent (petroleum ether or dichloromethane), and take the extract for toxic agent residue analysis. The mustard gas sample is analyzed by T-135 spectrophotometry, and the Viex sample is analyzed by chromatography HP6890-FID. The result is that the disinfection efficiency of the mustard gas disinfection reaction can reach more than 99% in 5 minutes, and the disinfection efficiency of Viex disinfection reaction in 5 minutes can also reach more than 99%.

Embodiment 3

[0052] Components: by mass fraction, sodium percarbonate 2%, acetylguanidine 2%, synergist 1.2%, add water to 100%.

[0053] Pipette 50mL of the prepared disinfectant solution into a 100mL three-neck round-bottomed flask, stir rapidly in the middle for 30min, use a micro-sampler to pipette 25μL of poison (mustard gas or Viex) into a 25mL stoppered test tube, and then add 5mL The pre-prepared disinfectant solution was shaken and mixed, and it was left to stand for 30 minutes. The residual poison was extracted with the extractant, and the extract was taken for the analysis of the poison residue. FID analysis. The result is that the disinfection rate of the mustard gas droplet standing for 30 minutes can reach 95%; the disinfection rate of Viex standing for 5 minutes can reach more than 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com