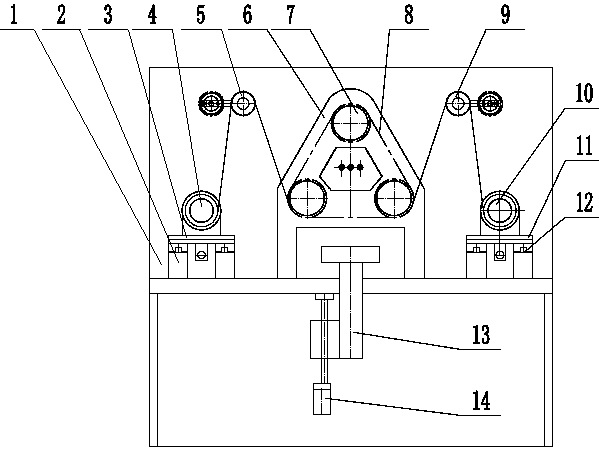

Diamond wire cutting machining equipment and cutting method of neodymium iron boron magnet

A diamond wire and processing equipment technology, applied in metal processing equipment, metal processing, grinding/polishing equipment, etc., can solve the problems of difficult installation and maintenance, poor stability, poor accuracy, etc., to achieve convenient maintenance, good stability, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

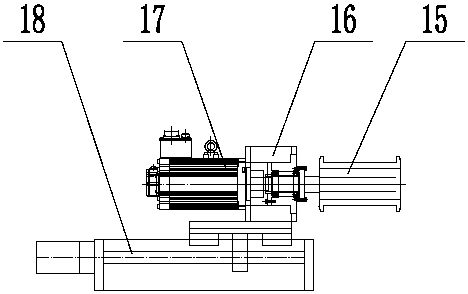

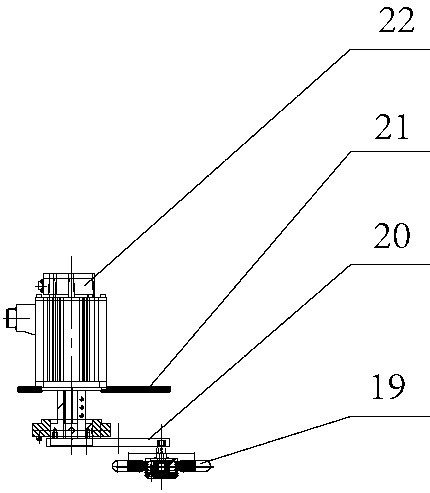

[0036] A diamond wire cutting processing method for NdFeB magnets. Firstly, four NdFeB magnets of 50×60×40mm are bonded to glass plates, and 40mm is the height direction, and then five glass plates (200×60× 40mm) bonded to a 20mm metal plate with an interval of 5mm to form a 200×320×60mm square, which is clamped to the workbench of the diamond wire multi-wire cutting processing equipment;

[0037] (2) Make a groove every 2mm on the grooved roller, the diameter of the diamond wire is 0.16mm, raise the worktable until the workpiece is close to the cutting diamond wire, set the torque of the retracting (releasing) wire torque wheel, the speed of the retracting (releasing) wire roller and After reciprocating motion parameters, grooved roller speed, and diamond wire feed rate, start the cutting fluid pump, start the diamond wire operation, and then start the table feed; the speed of the diamond wire is 1200m / min, and the feed rate of the diamond wire is 50mm / Cycle; stop after cutt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com