A low energy consumption super early strength cement adhesive for insulator glue mounting and preparation method thereof

An early-strength cement and low-energy-consumption technology, which is applied in the field of low-energy-consumption ultra-early-strength cement adhesive for insulator glue and its preparation, can solve the problems of insufficient production efficiency improvement, high energy consumption in the production process, large environmental impact, etc. The effect of curing time, improving production efficiency, and sufficient operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

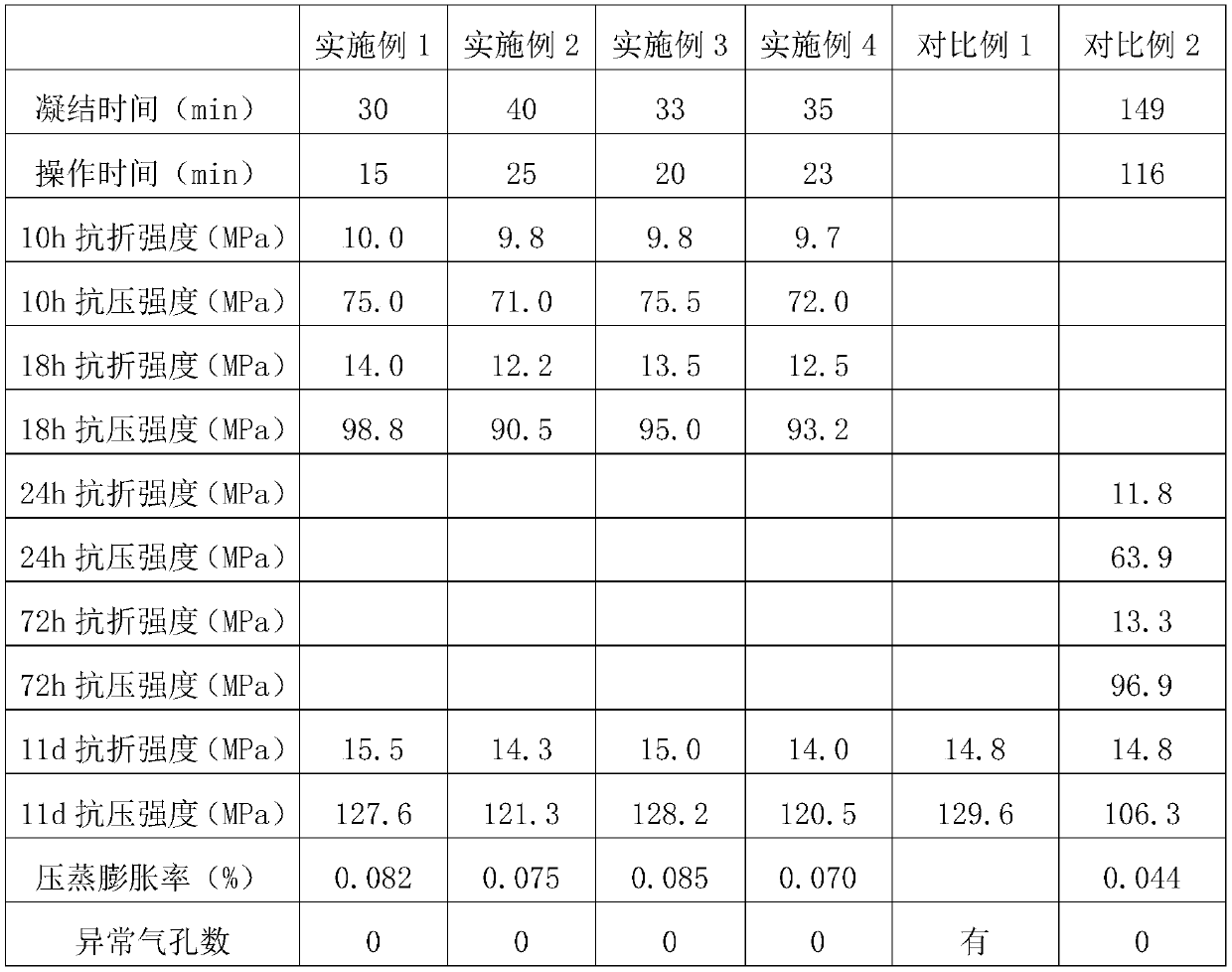

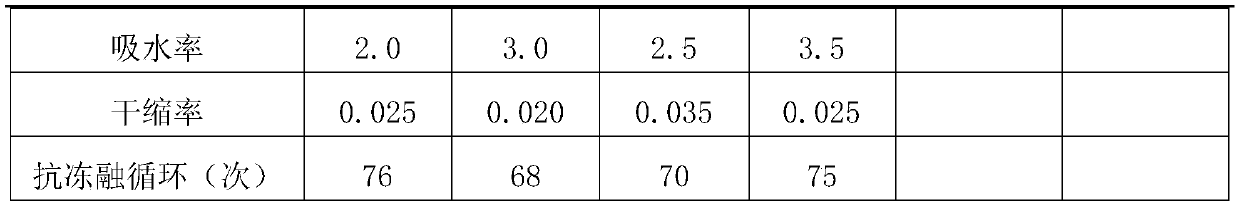

Examples

Embodiment 1

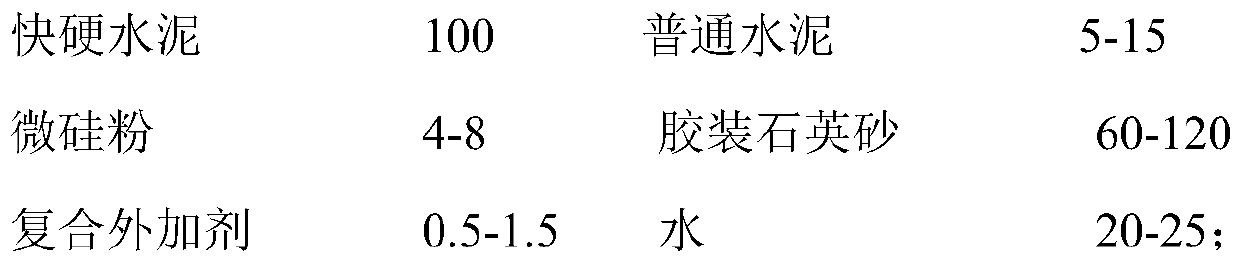

[0035] The low-energy consumption super-early-strength cement adhesive is composed of rapid hardening cement, ordinary cement, micro-silica fume, gelatinized quartz sand, composite admixture, and water in the following weight ratio:

[0036] Rapid hardening sulfoaluminate cement with a strength grade of 52.5MPa 100

[0037] P·O 52.5 cement 10

[0038] Micro silica fume 7.5

[0039] 40 mesh ~ 100 mesh glued quartz sand 65

[0040] Compound admixture 1.00

[0041] water 23

[0042] The composite admixture is composed of boric acid, polycarboxylate water reducer, lithium carbonate, starch ether, and polysiloxane defoamer in the following weight ratio of 100:35:10:20:20.

[0043] Low energy consumption super early strength cement binder, its preparation method comprises the following steps:

[0044] The three-step mixing method is adopted, that is, after weighing the raw materials according to the proportion, first put the ordinary silicon cement and the compound admixture in...

Embodiment 2

[0046] The low-energy consumption super-early-strength cement adhesive is composed of rapid hardening cement, ordinary cement, micro-silica fume, gelatinized quartz sand, composite admixture, and water in the following weight ratio:

[0047] Rapid hardening sulfoaluminate cement with a strength grade of 42.5MPa 100

[0048] P·O5 2.5 cement 5

[0049] Silica fume 6

[0050] 40 mesh ~ 100 mesh glued quartz sand 100

[0051] Compound admixture 0.55

[0052] water 25

[0053] The composite admixture is composed of boric acid, polycarboxylate water reducer, lithium sulfate, hydroxypropyl methylcellulose ether, and polysiloxane defoamer in the following weight ratio: 100:30:8:20:15 .

[0054] Low energy consumption super early strength cement binder, its preparation method is shown in Example 1.

Embodiment 3

[0056] The low-energy consumption super-early-strength cement adhesive is composed of rapid hardening cement, ordinary cement, micro-silica fume, gelatinized quartz sand, composite admixture, and water in the following weight ratio:

[0057] Rapid hardening sulfoaluminate cement with a strength grade of 52.5MPa 100

[0058] P·O 52.5 Cement 5.5

[0059] Microsilica 7.0

[0060] 40 mesh ~ 100 mesh glued quartz sand 70

[0061] Compound admixture 0.85

[0062] water 24

[0063] The composite admixture is composed of boric acid, polycarboxylate water reducer, lithium carbonate, hydroxypropyl methylcellulose ether, and polysiloxane defoamer in the following weight ratio: 100:40:9:15:20 .

[0064] Low energy consumption super early strength cement binder, its preparation method is shown in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com