Extraction method of natural paclitaxel

A technology of natural paclitaxel and extraction method, which is applied in the field of extraction of natural paclitaxel, and can solve the problems of resource and environmental damage, large amount of organic synthesis of paclitaxel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

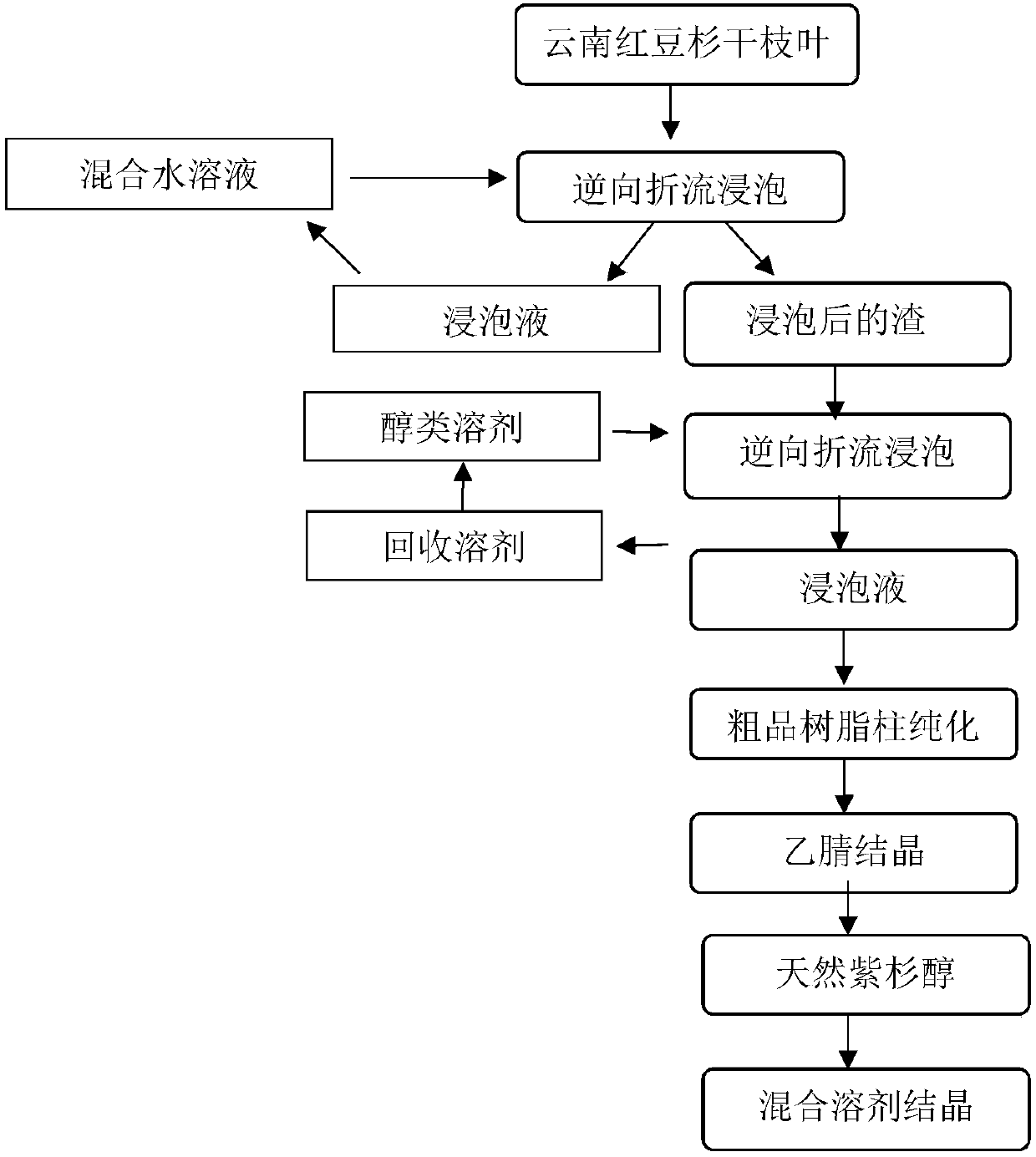

[0039] figure 1 It is a process flow diagram of the present invention, such as figure 1 Shown, a kind of extraction method of natural paclitaxel comprises the following steps:

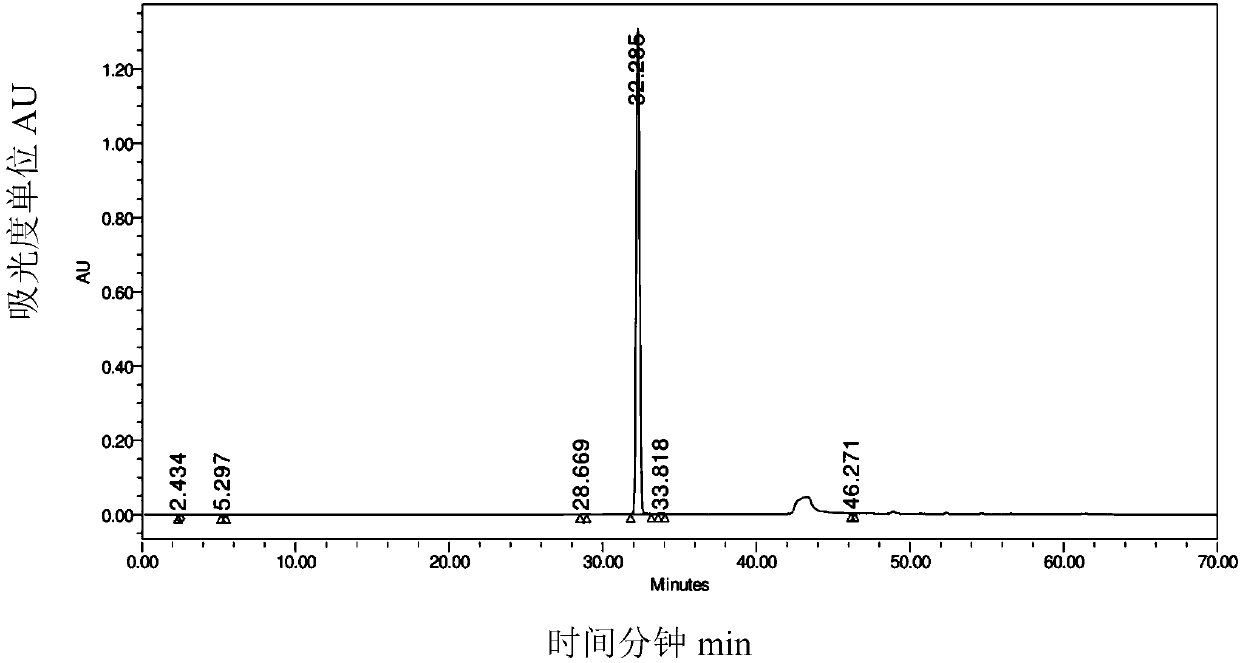

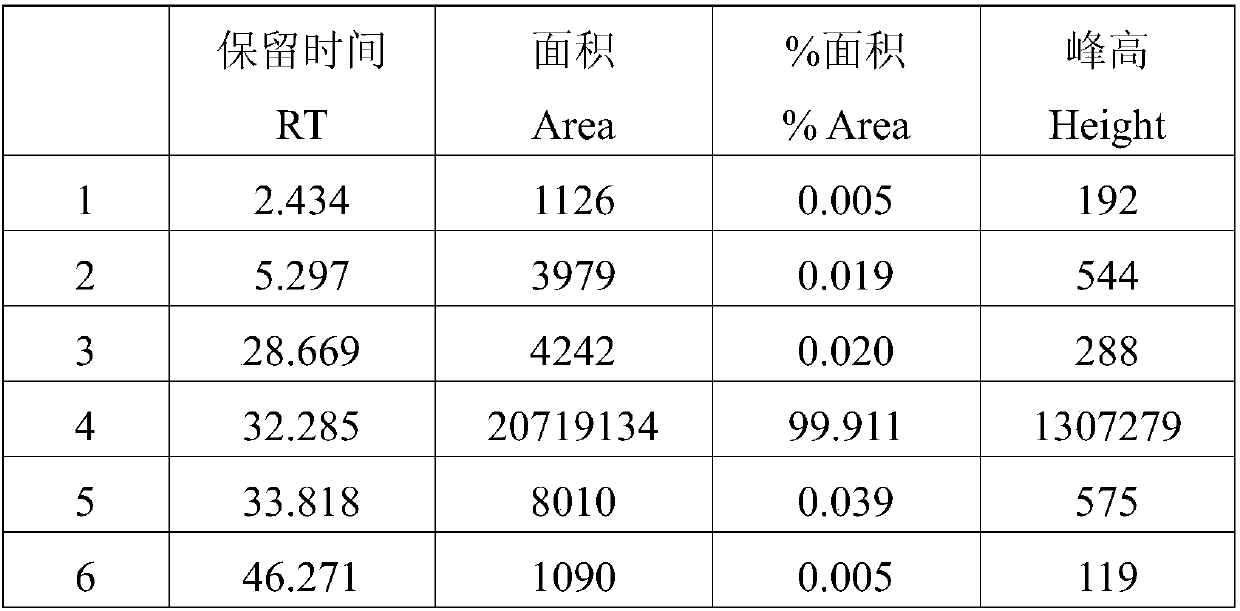

[0040] 10kg of crushed Taxus yunnanensis branches and leaves are evenly and continuously input from the entrance of the extraction equipment for 10 minutes, and the prepared 200kg mixed aqueous solution (0.1% acetic acid, 2.0% acetone aqueous solution) extract is injected into the extraction equipment at a constant speed at the same time, and the soaking solution flows to 1.0 ton storage tank, the soaking liquid is recovered and then transferred to the next batch of extraction procedures. After the solid extraction residue is squeezed by a press to remove most of the water, it is turned back into the extraction equipment, and 60kg of methanol is injected, all according to 10 minutes Feed at a complete speed, after the extraction is completed, concentrate the extract under reduced pressure until no liq...

Embodiment 2

[0042] A method for extracting natural paclitaxel, comprising the following steps:

[0043] 100kg of crushed Taxus yunnanensis branches and leaves are evenly and continuously input from the entrance of the extraction equipment for 80 minutes, and the prepared 2000kg mixed aqueous solution (0.1% acetic acid, 2.0% acetone aqueous solution) extract is injected into the extraction equipment at a constant speed at the same time, and the soaking solution flows to 10 tons of storage tank, the soaking liquid is recovered and then transferred to the next batch of extraction procedures. After the solid extraction residue is squeezed by a press to remove most of the water, it is turned back into the extraction equipment, and 600kg of methanol is injected, all according to 80 minutes Feed at a complete speed. After the extraction is completed, the extract is concentrated under reduced pressure until no liquid drops out. After 100L of acetone is dissolved, it is prepared with AB-8 resin. Th...

Embodiment 3

[0045] A method for extracting natural paclitaxel, comprising the following steps:

[0046]1.0 tons of crushed yew branches and leaves of Yunnan yew were fed continuously and evenly for 8 hours from the entrance of the extraction equipment, and 20 tons of the prepared mixed aqueous solution (0.1% acetic acid, 2.0% acetone aqueous solution) extract was injected into the extraction equipment at a uniform speed at the same time, and the soaking solution Self-flow to 50-ton storage tank, the soaking liquid is recovered and then transferred to the next batch of extraction procedures. After the solid extraction residue is squeezed by a press to remove most of the water, it is turned back into the extraction equipment, and 6.0 tons of methanol is poured into it. Feed according to the speed of 8 hours. After the extraction is completed, the extract is concentrated under reduced pressure until no liquid drips out. After 1000L of acetone is dissolved, it is prepared with AB-8 resin, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com