Method and device for controlling the quality of coking mixed oil

A technology for mixed oil and coking heavy oil, which is applied in tar processing, coking carbonaceous materials, and chemical processing of tar asphalt/petroleum asphalt/natural asphalt, etc. It can solve the problems of impurities and affecting the quality of coking mixed oil, and achieve The effect of using less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

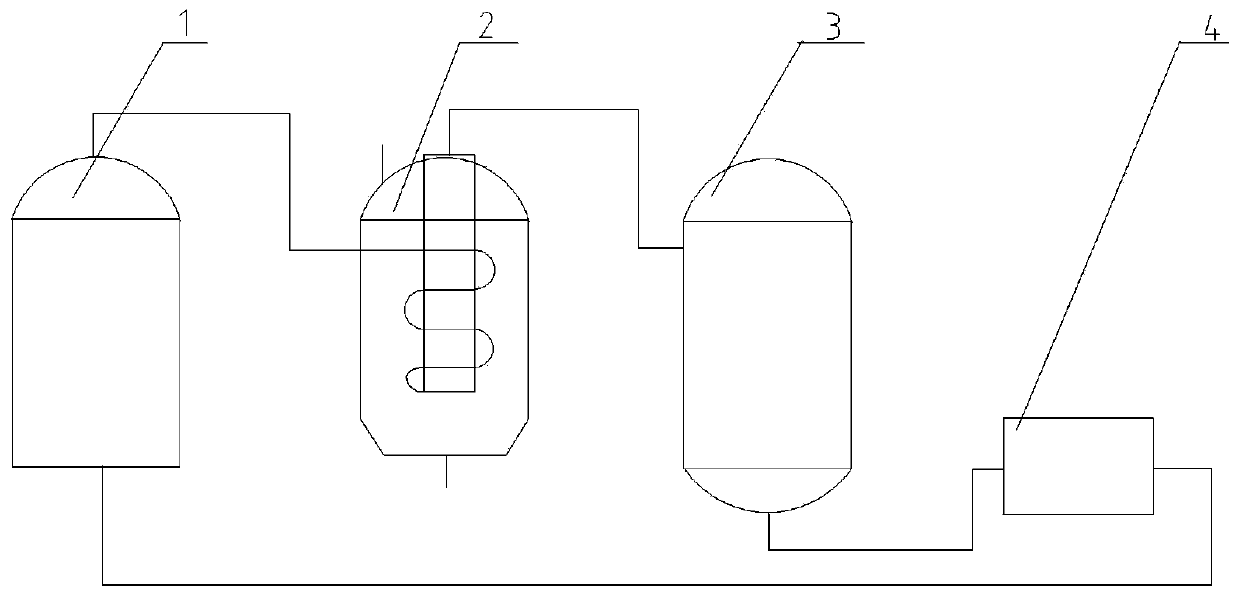

[0028] The control device for the quality of coking mixed oil in the production of coal series needle coke, such as figure 1 As shown, it consists of a coking tower 1, a swirl-type two-phase flow separation tower 2, a fractionation tower 3 and a heating furnace 4, and the gas outlet of the coking tower 1 is connected to the swirl-flow two-phase flow separation tower 2 through a pipeline , the gas outlet of the swirling two-phase flow separation tower 2 is connected with the fractionation tower 3 through a pipeline, and the bottom of the fractionation tower 3 is connected with the heating furnace 4 through a pipeline, and the heating furnace 4 is connected with the heating furnace 4 through a pipeline. The feed ports of the coking tower 1 are connected by pipelines.

Embodiment 2

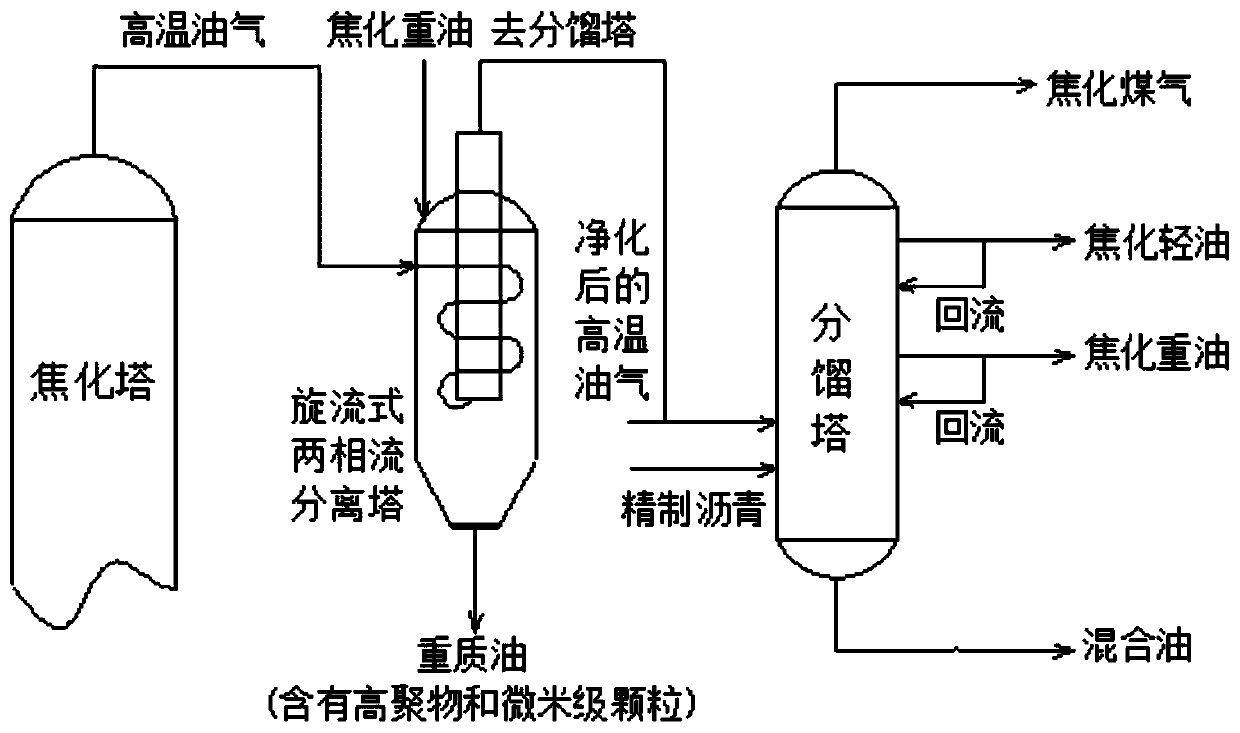

[0030] The method for controlling the quality of coking mixed oil in the production of coal-based needle coke described in this example is as follows: figure 2 shown, including the following steps:

[0031] (1) When the production feed of the coking tower is delayed for 6 hours, the high-temperature coking oil gas at 435°C from the top of the coking tower enters the high-temperature swirling two-phase flow separation tower in a tangential direction, and the tangential introduction of the airflow causes rotational movement.

[0032] (2) Spray 223kg / h of coking heavy oil on the upper part of the high-temperature swirl-type two-phase flow separation tower to control the gas outlet temperature at the top of the swirl-type two-phase flow separation tower, and separate high polymers and micron-sized solid particles from oil and gas, The purified high-temperature coking oil gas is discharged from the top of the high-temperature swirling two-phase flow separation tower, and the heavy...

Embodiment 3

[0040] The method for controlling the quality of coking mixed oil in the production of coal-based needle coke described in this embodiment includes:

[0041] (1) When the production feed of the coking tower is delayed for 10 hours, the high-temperature coking oil gas at 439 °C from the top of the coking tower enters the high-temperature swirling two-phase flow separation tower along the tangential direction.

[0042](2) Spray 236kg / h of coking heavy oil on the upper part of the high-temperature swirl-type two-phase flow separation tower to control the gas outlet temperature at the top of the swirl-type two-phase flow separation tower, and to separate high polymers and micron-sized solid particles from oil and gas, The purified high-temperature coking oil gas is discharged from the top of the high-temperature swirling two-phase flow separation tower, and the heavy oil containing polymers and micron-sized solid particles is discharged from the tower and used as fuel oil. The puri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com