Electrostatic spinning receiving device for preparing axial orientation tubular tissue engineering material

A receiving device, electrospinning technology, applied in textile and papermaking, filament/thread forming, fiber processing, etc., to achieve the effects of controllable thickness, regular surface, and uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

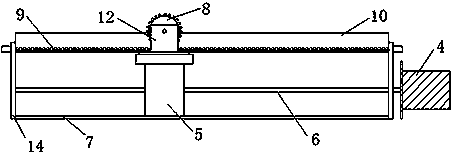

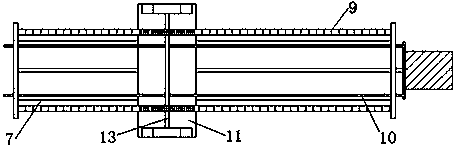

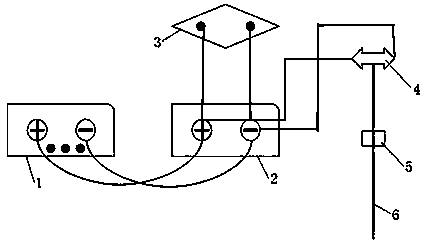

[0036] An electrospinning receiving device for preparing axially oriented tubular tissue engineering materials, such as Figure 1-4 As shown, it includes a propeller, the propeller is connected with a spinneret 20, an electrostatic high voltage application device is provided at the spinneret 20, the needle of the spinneret 20 is connected to the positive electrode of the electrostatic high voltage application device, and a receiving device is provided below the spinneret 20 . The receiving device includes a pair of receiving pole plates 10 and a reel 13 arranged vertically and parallel to each other. The receiving pole plate 10 is connected to the negative pole of the electrostatic high voltage application device and grounded. The two ends of the receiving pole plate 10 are installed on the bracket 14. It is arranged on the two receiving pole plates 10 and placed on the upper edge of the two receiving pole plates 10 . The distance between two receiving pole plates 10 is 40 mm...

Embodiment 2

[0051] An electrospinning receiving device for preparing axially oriented tubular tissue engineering materials, the structure is the same as that of Example 1, the difference is that: the distance between the two receiving plates 10 is 30 mm; the spinneret 20 to the receiving plate 10 has a distance of 140mm. The cycle of reciprocating motion of the reel 13 is 5 s, the effective stroke is 150 mm, the linear velocity of the reel 13 is 60 mm / s; the rotational angular velocity of the reel 13 is 10 rad / s.

[0052] The surface of the reel 13 is coated with PEO (polyethylene oxide).

[0053] The spinning solution is a polycaprolactone solution with dichloromethane and dimethylformamide as solvents, and the concentration is 16w / v%.

[0054] The parameters of the electrospinning process are set as follows: the propeller propulsion rate is 2.5ml / h, and the electrostatic high voltage is 10kV.

Embodiment 3

[0056] An electrospinning receiving device for preparing axially oriented tubular tissue engineering materials, the structure is the same as that of Example 1, the difference is that: the distance between the two receiving plates 10 is 60mm; the spinneret 20 to the receiving plate The distance of 10 is 200mm. The period of reciprocating motion of the reel 13 is 20s, the effective stroke is 400mm, the linear velocity of the reel 13 is 20mm / s; the rotational angular velocity of the reel 13 is 1rad / s.

[0057] The surface of the reel 13 is coated with PVA (polyvinyl alcohol).

[0058] The spinning solution is a solution of L-polylactic acid with dichloromethane and dimethylformamide as solvents, and the concentration is 10w / v%.

[0059] The parameters of the electrospinning process are set as follows: the propulsion rate of the propeller is 1ml / h, and the electrostatic high voltage is 15kV.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com