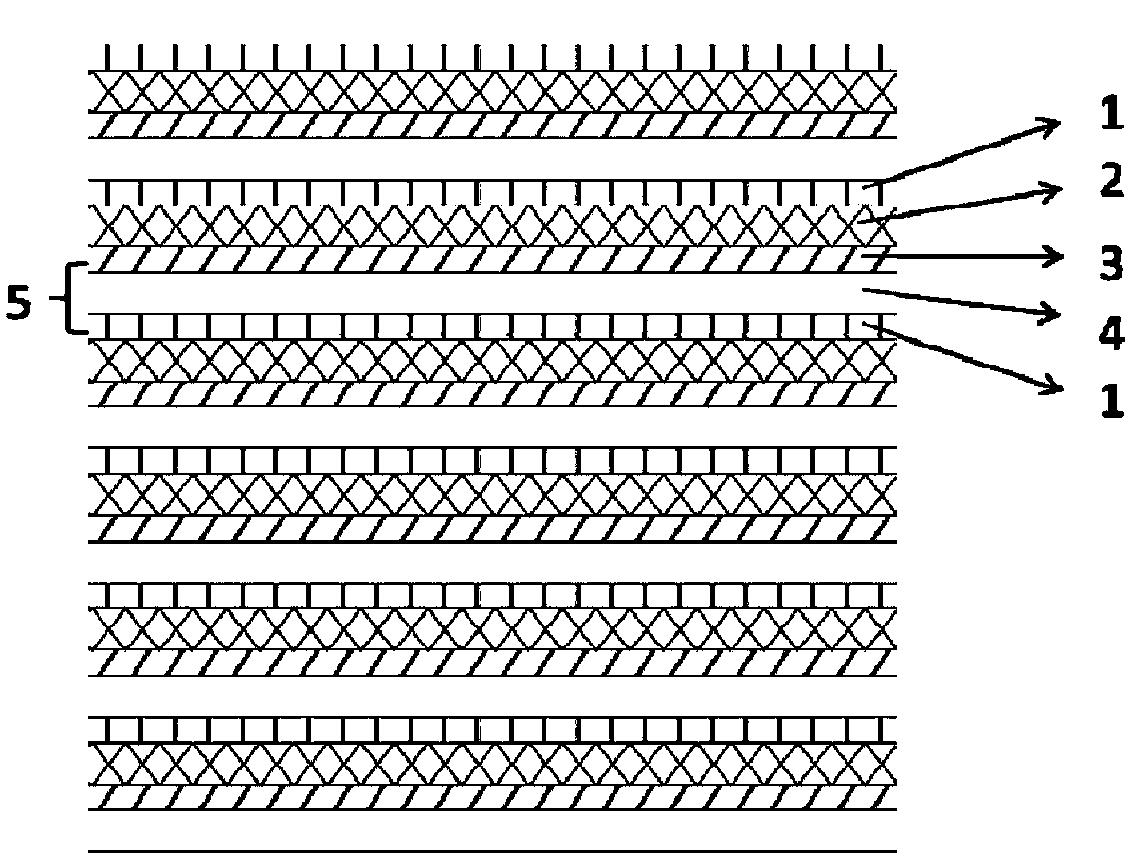

Bipolar current collecting body and bipolar solid-state lithium secondary battery assembled by bipolar current collecting body

A secondary battery, bipolar technology, used in secondary batteries, electrode carriers/current collectors, battery electrodes, etc., can solve the problems of large mass per unit area, unstable lithium, affecting the specific energy density of batteries, etc. The effect of energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

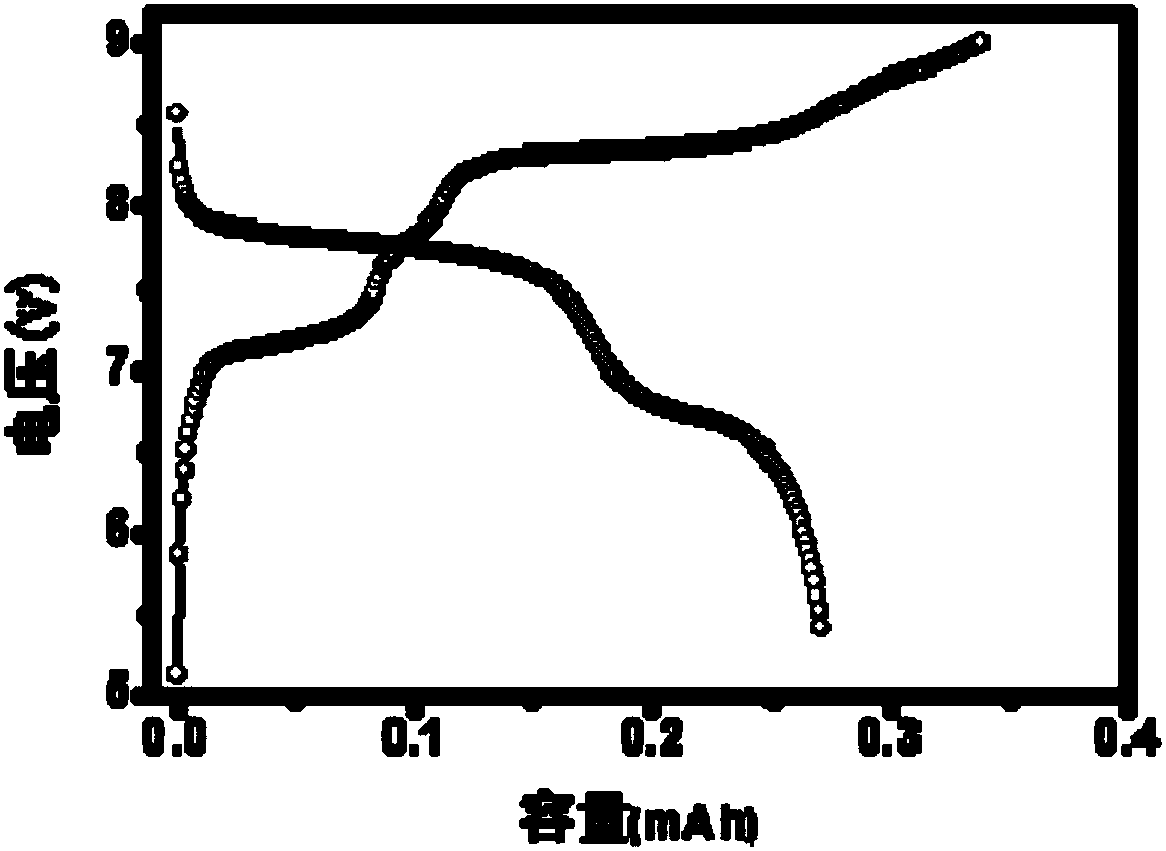

Embodiment 1

[0031] The assembly of bipolar solid-state lithium secondary batteries includes the preparation of bipolar electrodes, the preparation of solid electrolytes and the assembly of batteries. The specific implementation process is as follows:

[0032] (1) Preparation of polymer-carbon material composite conductive film:

[0033] The polyethylene and carbon black were weighed at a ratio of 85:15, then melted and mixed uniformly, and cast into a film to obtain a composite conductive film with a thickness of 30 μm.

[0034] (2) Preparation of electrodes containing only the positive electrode layer

[0035] The composite conductive film prepared in step (1) is used as a current collector, and the positive electrode slurry is only coated on one side, and the other side is blank.

[0036] The specific manufacturing steps are as follows:

[0037] The cathode material used is lithium iron manganese phosphate (LiFe 0.8 mn 0.2 PO 4 ), the conductive agent used is Super P, the binder is...

Embodiment 2

[0061] The assembly of bipolar solid-state lithium secondary batteries includes the preparation of bipolar electrodes, the preparation of solid electrolytes and the assembly of batteries. The specific implementation process is as follows:

[0062] (1) Preparation of polymer-carbon material composite conductive film:

[0063] The polypropylene and carbon black are weighed according to the ratio of 85:15, then melted and mixed uniformly, and cast into a film to obtain a composite conductive film.

[0064] Steps (2)-(5) refer to steps (2)-(5) of Example 1.

[0065] (6) Assembly of bipolar solid-state lithium secondary battery:

[0066] a The solid electrolyte membrane prepared by step (5) is pressed on the positive electrode side of the electrode that only contains the positive electrode layer prepared in step (2), and the pressure used is 8MPa;

[0067] B then pressing the bipolar electrode negative electrode side that step (4) is made on the electrolyte layer;

[0068] c the...

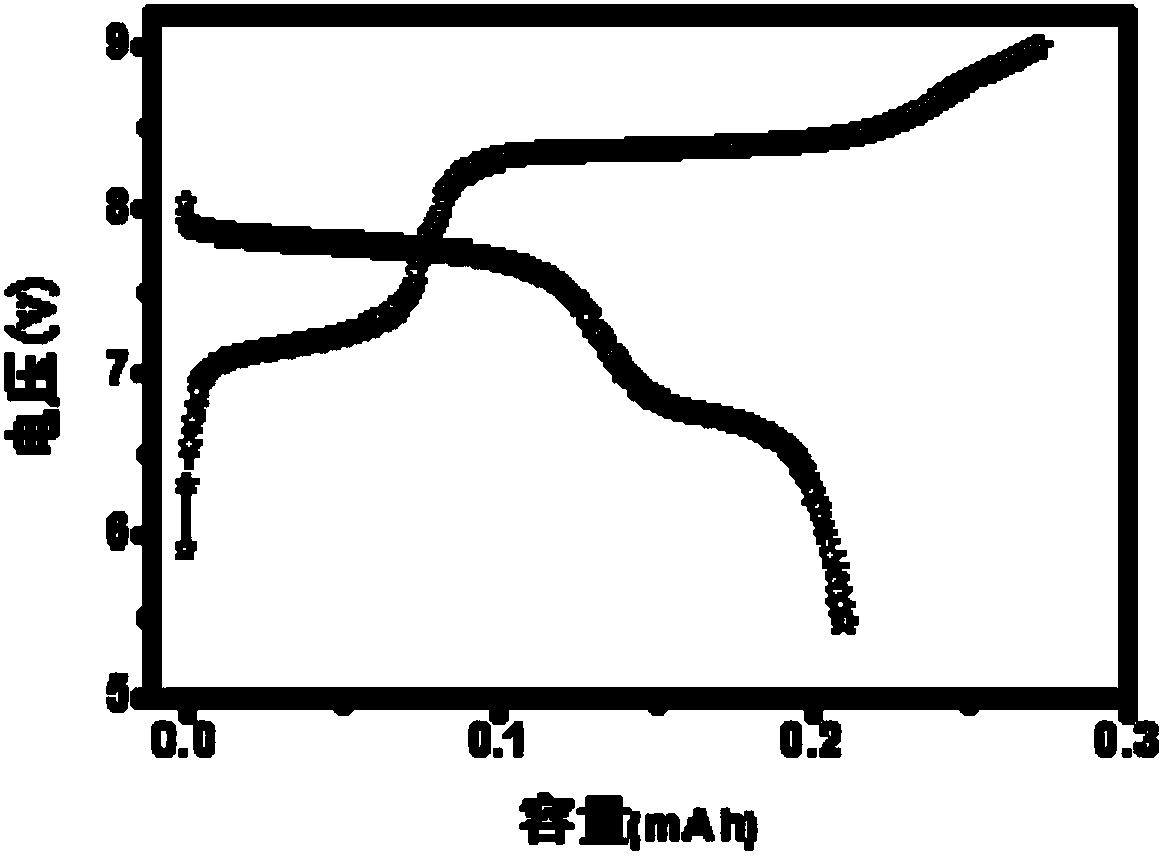

Embodiment 3

[0071] The steps and conditions refer to Example 2, the difference is that the inorganic component of the solid electrolyte is replaced by LATP from LAGP.

[0072] The electrochemical properties of its test results are as follows: image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com