Protection device for stent, manufacturing method thereof, and medical device

A technology of protection device and medical device, applied in the field of medical devices, can solve the problems of increasing diameter, unable to meet the needs of maintaining the diameter size of polymer stents, etc., and achieve the requirements of avoiding damage and wear, easy sterilization, and simple operation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

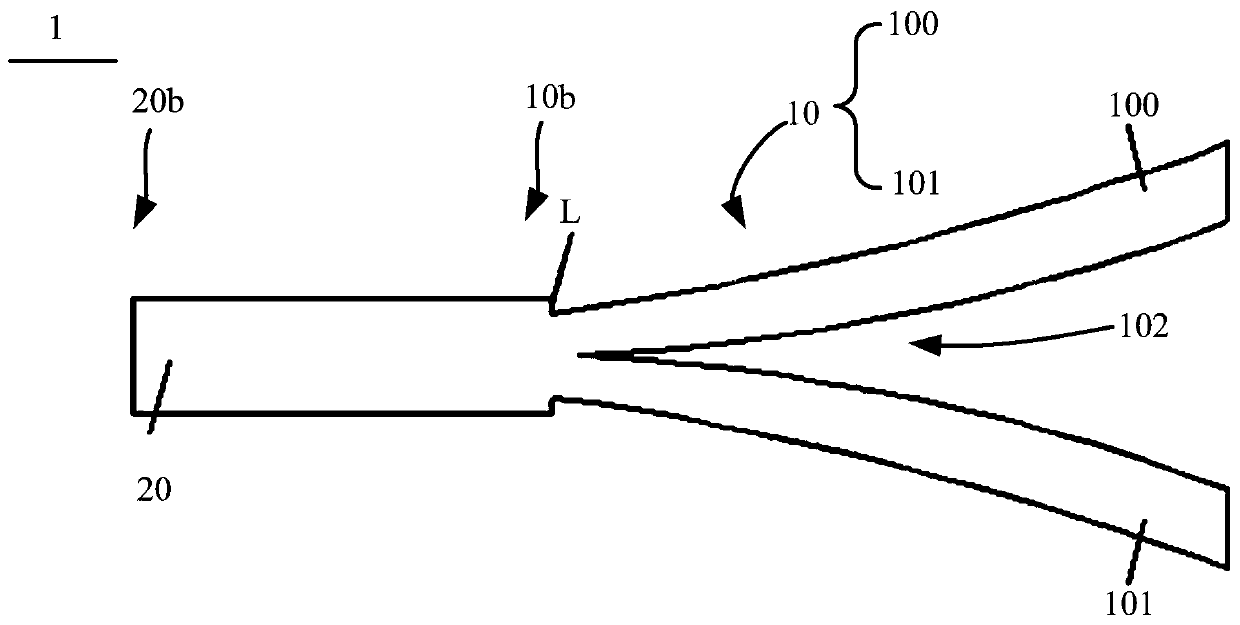

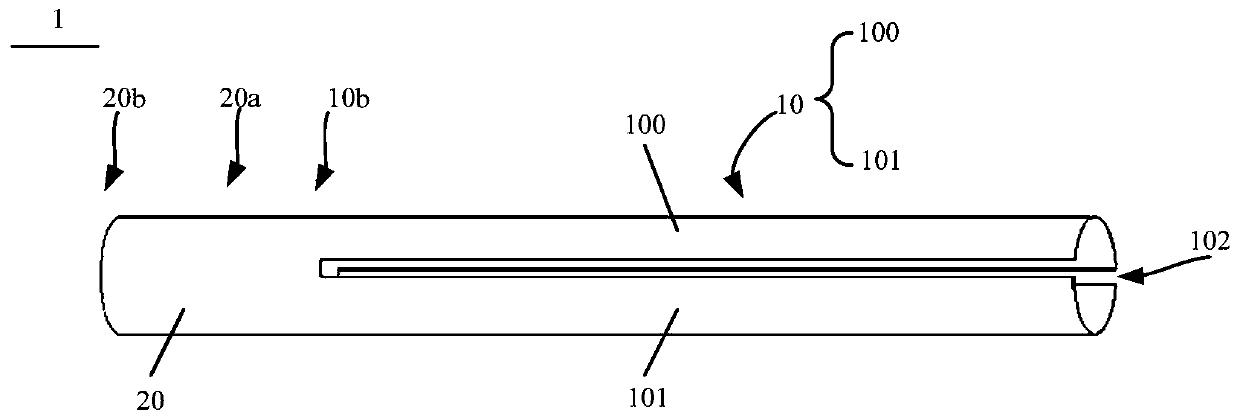

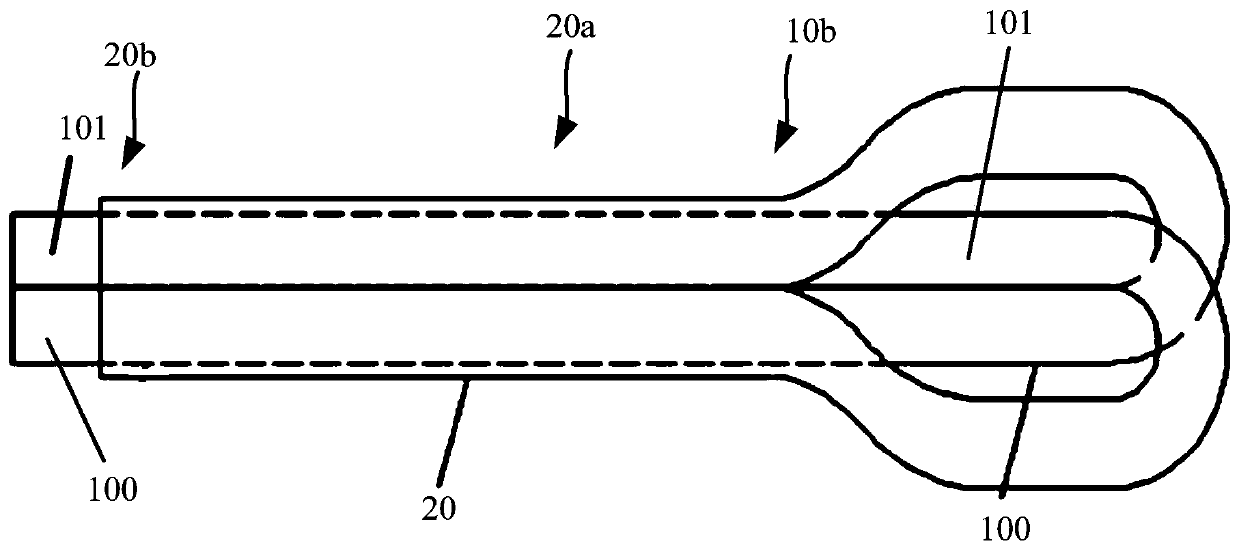

[0044] Please refer to Figure 1b , figure 2 and image 3 , the protective device of the stent of the present invention includes: a sheath, one end of the sheath forms a protective sheath 10, and the other end forms a constraining sheath 20, and the protective sheath 10 is located at the formed part of the constraining sheath 20. In the accommodating space; the bracket 2 is located in the accommodating space formed by the protective sheath 10, a connection section is included between the protective sheath 10 and the restraining sheath 20 of the sheath, and the sheath also includes everything An opening 102, the slit 102 extends along the direction of the connecting section and the protective sheath 10, the slit 102 forms the connecting section and the protective sheath 10 into a first part 100 and a second part 101 separated from each other . Wherein, the material of the bracket is Pebax, PTFE, polyethylene, polycarbonate, polyamide or nylon.

[0045] Please refer to Fi...

Embodiment 2

[0053] This embodiment provides a method for manufacturing a protective device for a stent. The method for manufacturing the protective device for a stent includes: preparing a pipe, and dividing one end of the pipe into a first separation part and a second separation part in the axial direction , the undivided end of the pipe forms a constraining sheath, the first separation part and the second separation part are placed in the lumen of the constraining sheath, and the length of the constraining sheath is less than or equal to the total length of the pipe one-third of the length. Wherein, the first separating portion and the second separating portion pass through the lumen of the first section and at least partly pass through the lumen of the first section, the advantage of this is that when the first separating portion and the second The separation part passing through the lumen of the first section will naturally separate to form an opening, so that the relative movement be...

Embodiment 3

[0056] This embodiment provides a medical device. Compared with the protective device for the stent in Embodiment 1, the medical device is different in structure. The medical device includes: a stent and a sheath, and the stent is covered by Pressed on a balloon catheter; the sheath includes a first section and a second section, the first section is a tubular structure, and the second section is divided into a first separation part and a second section through an incision The separation part, the first separation part and the second separation part are accommodated in the lumen of the first segment, and the stent and the balloon catheter are accommodated in the lumen formed by the first separation part and the second separation part middle.

[0057] In order to better understand the operation method of how to remove the bracket from the protection device, three examples are used below to illustrate several protection devices with different structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com