Method for inhibiting sludge bulking in secondary sedimentation tank

A technology of sludge bulking and secondary settling tanks, which is applied in chemical instruments and methods, water/sludge/sewage treatment, feeding/discharging devices of settling tanks, etc., can solve problems such as uneconomical, practical, and complicated, and achieve Effects of improving clarity, inhibiting sludge bulking and floating, and inhibiting viscous expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

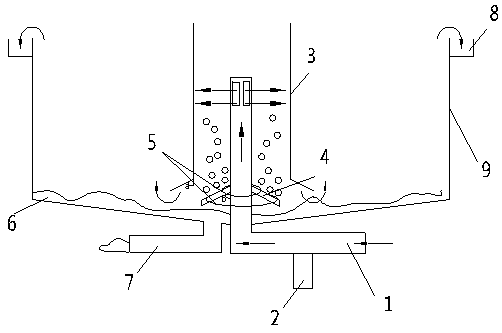

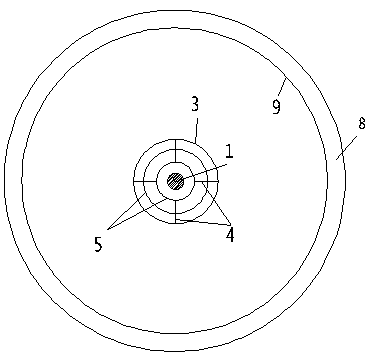

[0025] The height of the secondary settling tank adopted in this embodiment is 0.5m, and the diameter is 1m. The diameter of the sleeve is 0.18m, the top of the sleeve is 0.4m higher than the liquid level of the secondary sedimentation tank, the angle a between the bell mouth and the water inlet pipe wall is 60°, the horizontal projection length of the bell mouth is 0.085m, and the distance between the bottom end of the bell mouth is 2 The vertical distance from the bottom of the settling tank is 0.1m. Set 4 support frames at intervals around the water inlet pipe, the angle b between the support frame and the water inlet pipe wall is 60°, the horizontal projection length of the support frame is 0.072m, and the distance from the bottom end of the support frame to the bottom of the secondary sedimentation tank is 0.1m . Two rings of aeration coils are fixed on the support frame. A dissolved oxygen meter is installed inside the sleeve to monitor and control the dissolved oxygen...

Embodiment 2

[0028] Process and operating conditions are the same as in Example 1. The difference is: when the measured SVI value is 200mg / L, take another sample for measurement after 10 minutes, and the SVI value is 280mg / L. At this time, the sewage in the sleeve is B:N=100:3, B:P=100:0.3, and additional Potassium dihydrogen phosphate makes B:P=100:0.6. At this time, the aeration system is turned on, and after repeating 6 groups, the dissolved oxygen concentration in the sleeve is stable at about 2.5mg / L, and the SVI value of the sewage is 120mg / L. Compared with the treatment effect of Example 1, the sludge quality is better, the treatment effect is also improved, and the number of aeration groups can be reduced.

Embodiment 3

[0030] The height of the secondary settling tank adopted in this embodiment is 0.5m, and the diameter is 1m. The diameter of the sleeve is 0.25m, the top of the sleeve is 0.3m higher than the liquid level of the secondary sedimentation tank, the angle a between the bell mouth and the water inlet pipe wall is 30°, the horizontal projection length of the bell mouth is 0.1m, and the distance from the bottom of the bell mouth is 2 The vertical distance at the bottom of the settling tank is 0.12m. Set 4 support frames at intervals around the water inlet pipe, the angle b between the support frame and the water inlet pipe wall is 30°, the horizontal projection length of the support frame is 0.08m, and the distance from the bottom of the support frame to the bottom of the secondary sedimentation tank is 0.12m . Two rings of aeration coils are fixed on the support frame. A dissolved oxygen meter is installed inside the sleeve to monitor and control the dissolved oxygen concentration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com