Preparation method for zeolite-like imidazate framework (ZIFs) coated inorganic oxide core-shell material

An inorganic oxide and encapsulation technology, applied in the field of materials, can solve the problems of complex preparation equipment, difficult product separation, harsh preparation conditions, etc., and achieve the effect of simple operation, mild conditions and good universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

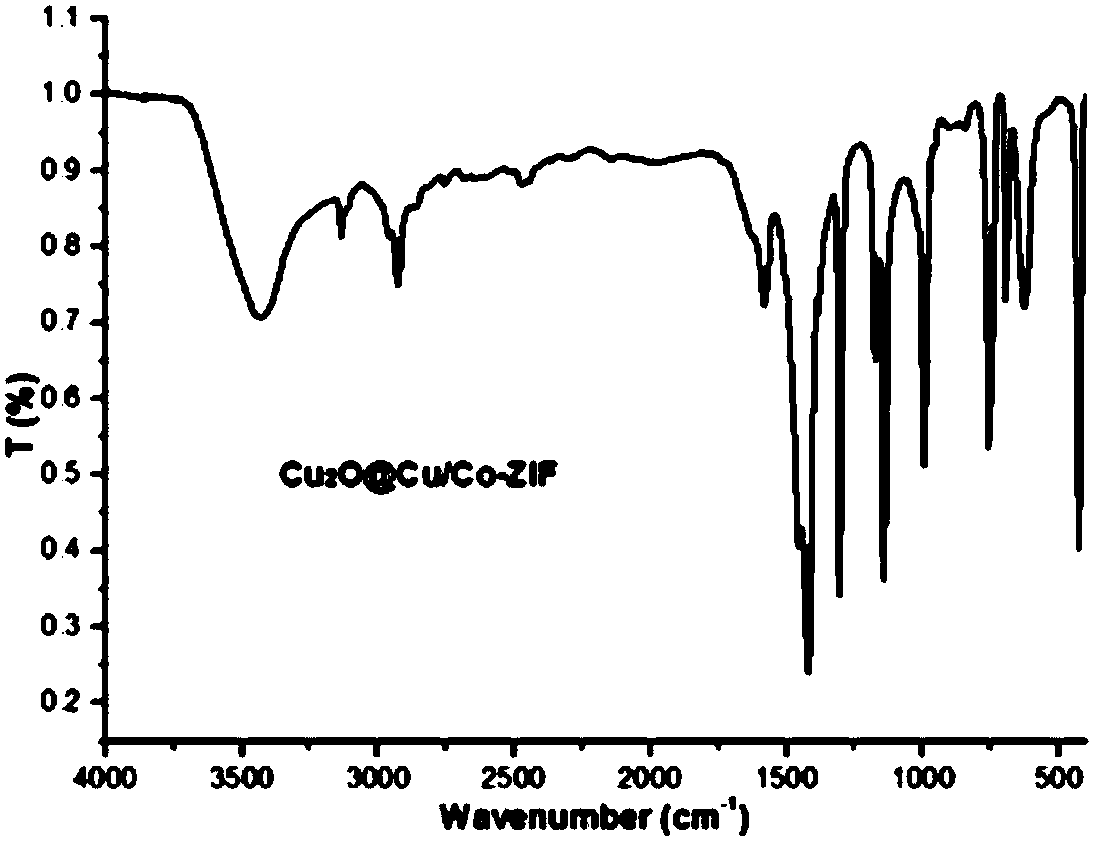

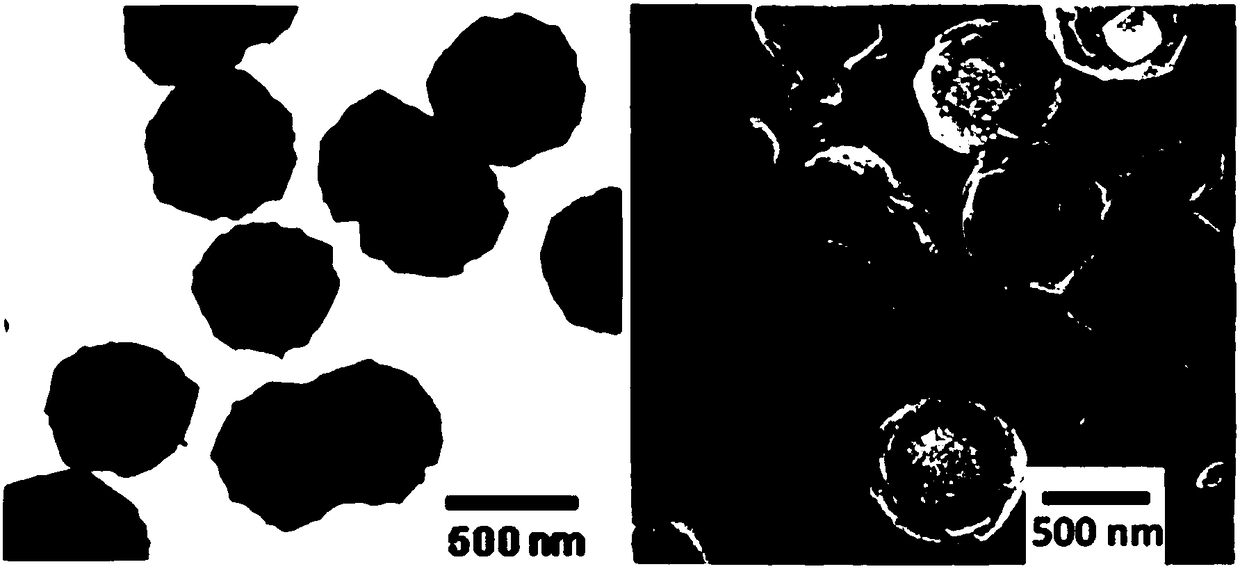

[0030] Embodiment 1: 0.065 gram of layered spherical hollow cuprous oxide, 30 milliliters of methyl alcohol, join in the there-necked flask of 100 milliliters, 2-methylimidazole (0.17~0.22 gram) methanol solution and cobalt nitrate (0.08~ 0.11 g) of methanol solution was slowly added to the flask while stirring, and the stirring was maintained at room temperature and pressure for 1-8h. Stirring was then stopped, and the entire reaction mixture was transferred to a centrifuge tube. Centrifuge at 4500rpm, wash the solid product several times with methanol, dry the product in an oven at 80°C for 12 hours, and collect the solid product. Then sampling infrared analysis (FT-IR, figure 1 ), and observe the position of the absorption peak. Observation of sample morphology and size by TEM and SEM (SEM and TEM, figure 2 ). The results showed that the product was Cu 2 O(hollow)@ZIFs core-shell structure.

Embodiment 2

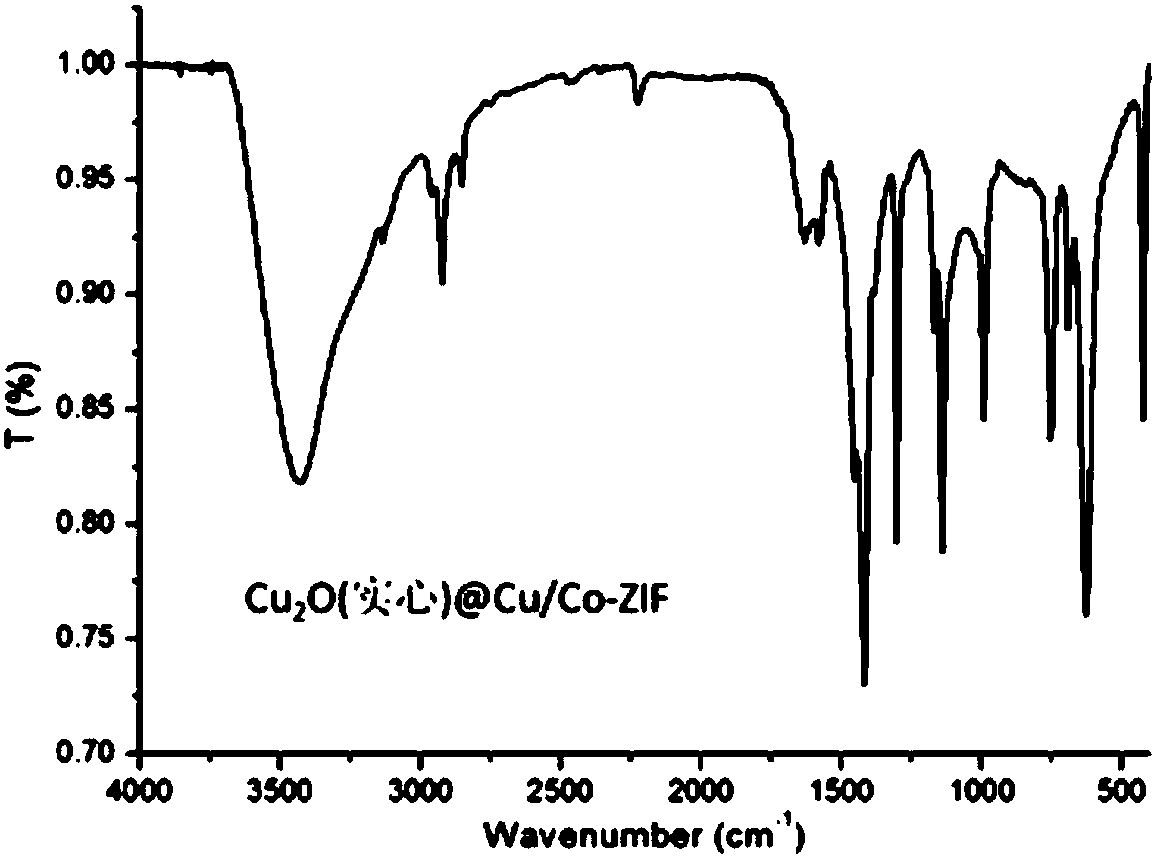

[0031] Embodiment 2: 0.065 gram of solid spherical cuprous oxide, 30 milliliters of methyl alcohol, join in the there-necked flask of 100 milliliters, 2-methylimidazole (0.17~0.22 gram) methanol solution and cobalt nitrate (0.08~0.11 gram ) methanol solution was slowly added to the flask while stirring, and the stirring was maintained at room temperature and pressure for 1-8h. Stirring was then stopped, and the entire reaction mixture was transferred to a centrifuge tube. Centrifuge at 4500rpm, wash the solid product several times with methanol, dry the product in an oven at 80°C for 12 hours, and collect the solid product. Then sampling infrared analysis (FT-IR, image 3 ), and observe the position of the absorption peak. by TEM Figure 4 The shape and size of the samples were observed. It was confirmed that the obtained product was a core-shell structure material. The results showed that the product was Cu 2 O (solid) @ZIFs core-shell structure.

Embodiment 3

[0032] Embodiment 3: 0.065 gram of hollow lamellar spherical cuprous oxide, 30 milliliters of methyl alcohol, join in the there-necked flask of 100 milliliters, 2-methylimidazole (0.17~0.22 gram) methanol solution and cobalt nitrate (0.08~ 0.11 g) of methanol solution was quickly added to the flask while stirring, and the stirring was maintained at room temperature and pressure for 1-8h. Stirring was then stopped, and the entire reaction mixture was transferred to a centrifuge tube. After centrifugation at 4500 rpm, the solid product was washed several times with methanol, and the product was dried in an oven at 80° C. for 12 hours. The ZIFs core-shell structure was not obtained when the product was collected. The product was observed by TEM (TEM, Figure 5 ) and infrared analysis of the product did not form a core-shell structure (FT-IR, Figure 6 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com