Method for preparing beer from residual solid medium of Isaria cicadae Miquel

A technology for cicadae fungus and beer, which is applied in the field of preparation of cicadae fungus beer, can solve the problems of waste of resources, environment, harm, etc., and achieve the effects of reducing the discharge of solid waste, increasing the type and content, and improving the taste and taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

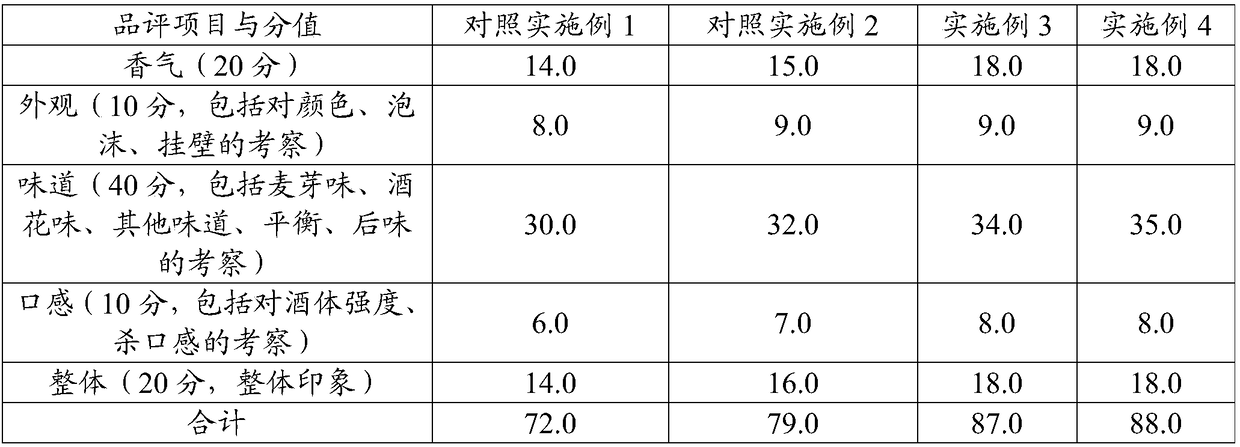

Examples

Embodiment 1

[0028] The preparation of embodiment 1 mycoplasma

[0029] Mix wheat and water evenly at a ratio of 1:1.5, and sterilize; inoculate the cicadae strains that have been expanded and cultivated, and obtain fruiting bodies through solid culture; after harvesting the fruiting bodies, take the remaining solid culture residues to obtain For wheat fungus. The bacteria were dried, pulverized, and sterilized at 126°C for 45 minutes.

Embodiment 2

[0030] The preparation of embodiment 2 mycoplasma

[0031] Mix rice and water evenly in a ratio of 1:1.5, and sterilize; inoculate the cicadae strains that have been expanded and cultivated, and obtain fruiting bodies through solid culture; after harvesting the fruiting bodies, take the remaining solid culture residues to obtain For rice fungus. The bacteria were dried, pulverized, and sterilized at 126°C for 45 minutes.

Embodiment 3

[0032] The preparation of embodiment 3 cicadae mycoplasm yellow beer

[0033] Step a, take 0.55 kg of cicadae fungus from Example 1 or 2, add 5 L of 50% ethanol solution, extract three times at 60 ° C, extract for 2 hours each time, combine the ethanol extraction solution, concentrate under reduced pressure, and obtain 1 L of concentrated solution;

[0034] Step b, add the residue after ethanol extraction in step a to 13.125L of water, boil for 1 hour, and keep the liquid level;

[0035] Step c, add 7.875L of water decoction in step b to 20°C water, adjust to 70°C, add crushed malt according to the following ratio: 3.9kg of basic malt, 0.164kg of wheat malt, 0.164kg of burnt malt, keep warm for saccharification for 1h ; After the saccharification is completed, use the spent grains layer to filter to obtain sugar juice;

[0036] Step d, boil the sugar juice obtained in step c, and add hops in the following order: after boiling for 15 minutes, add 5g Nugert hops, after boiling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com