Surface strengthening heat treatment method capable of improving hardness gradient

A heat treatment method and surface strengthening technology, applied in the field of heat treatment, can solve the problems of parts performance decline, insufficient surface hardness of workpiece, insufficient hardness, etc., to improve surface hardness and hardness gradient, shorten diffusion time and total time, and reduce residual austenite. body mass effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

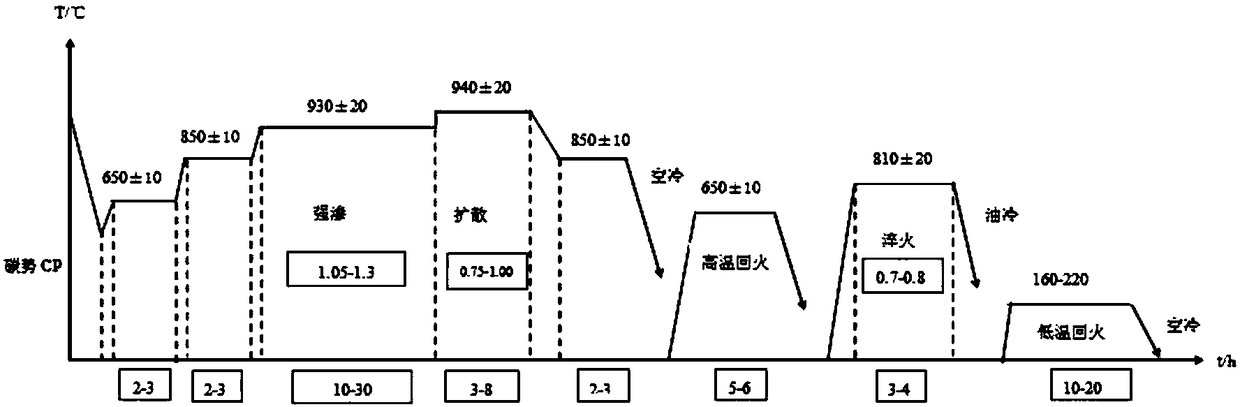

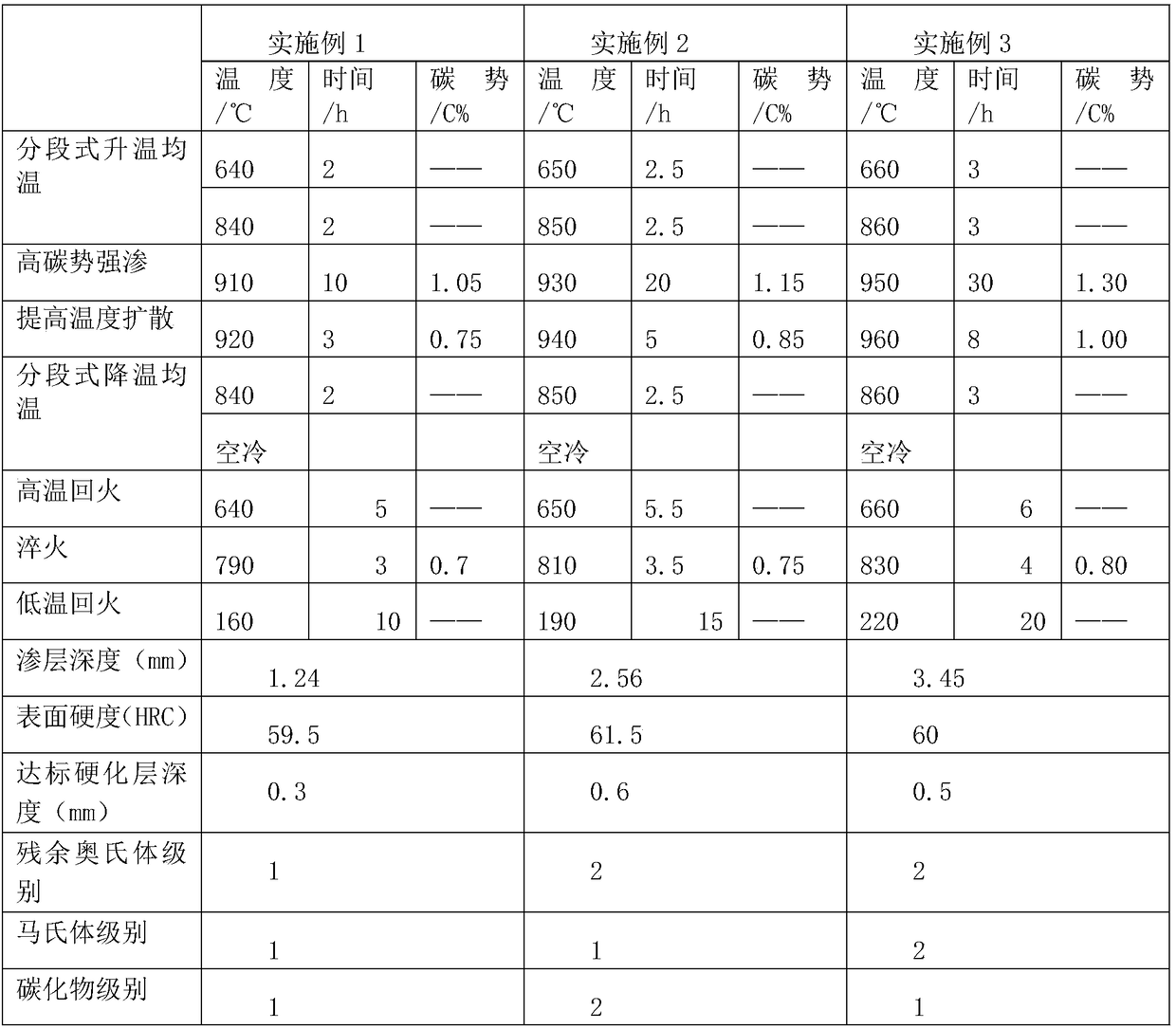

[0033] A surface strengthening heat treatment method capable of increasing the hardness gradient, comprising the following steps:

[0034] S01. Segmented heating and uniform temperature, place the parts in the heating furnace and heat to 640°C, keep warm for 2-3h, continue to heat to 840°C, keep warm for 2h;

[0035] S02. High carbon potential and strong infiltration. The parts continue to be heated to 910°C with the heating furnace, and the carburizing agent is passed into the heating furnace for carburization. The carbon potential CP is controlled at 1.05C%, and the carburizing time is 10h;

[0036] S03. Increase the temperature diffusion. After the step S02 is completed, increase the temperature of the heating furnace to 920° C., and reduce the carbon potential CP to 0.75C% to enter the diffusion stage, and the diffusion time is 3 hours;

[0037] S04. Segmented cooling and uniform temperature. After step S03 is completed, reduce the temperature of the heating furnace, and t...

Embodiment 2

[0043] A surface strengthening heat treatment method capable of increasing the hardness gradient, comprising the following steps:

[0044] S01. Segmented heating and uniform temperature, place the parts in the heating furnace and heat to 650°C, keep warm for 2.5h, continue to heat to 850°C, keep warm for 2.5h;

[0045] S02. High carbon potential and strong infiltration. The parts continue to be heated to 930°C with the heating furnace, and the carburizing agent is passed into the heating furnace for carburization. The carbon potential CP is controlled at 1.15C%, and the carburizing time is 20h;

[0046] S03. Increase the temperature diffusion. After step S02 is completed, increase the temperature of the heating furnace to 940° C., and reduce the carbon potential CP to 0.85C% to enter the diffusion stage, and the diffusion time is 5 hours;

[0047] S04. Segmented temperature reduction and uniform temperature. After step S03 is completed, reduce the temperature of the heating fu...

Embodiment 3

[0053] A surface strengthening heat treatment method capable of increasing the hardness gradient, comprising the following steps:

[0054] S01. Segmented heating and uniform temperature, place the parts in the heating furnace and heat to 660°C, keep warm for 3h, continue heating to 860°C, keep warm for 3h;

[0055] S02. High carbon potential and strong infiltration. The parts continue to be heated to 950°C with the heating furnace, and the carburizing agent is passed into the heating furnace for carburization. The carbon potential CP is controlled at 1.30C%, and the carburizing time is 30h;

[0056] S03. Increase the temperature diffusion. After step S02 is completed, increase the temperature of the heating furnace to 960° C., and reduce the carbon potential CP to 1.00C% to enter the diffusion stage, and the diffusion time is 8 hours;

[0057] S04. Segmented cooling and uniform temperature. After step S03 is completed, reduce the temperature of the heating furnace, and the par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com