Reagent for detecting urine microalbumin and application of reagent

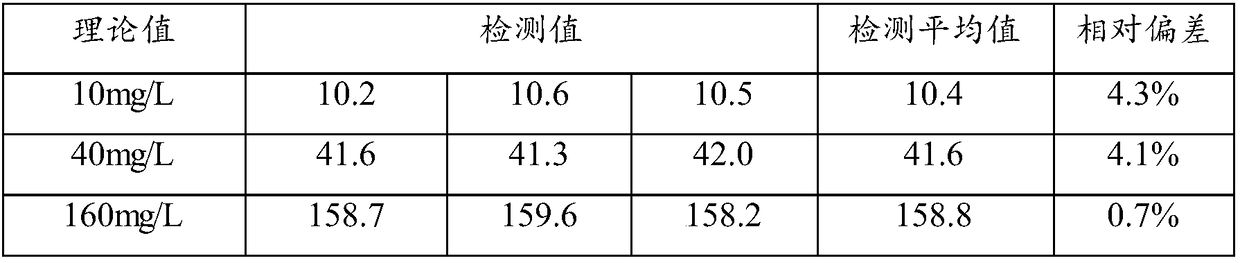

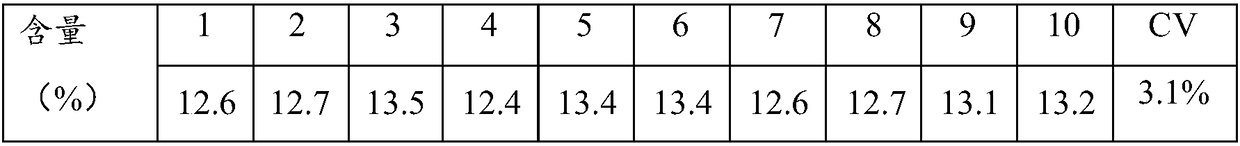

A microalbumin and urine technology, applied in the field of medical testing, can solve the problems of high false positives, inability to give content, insufficient precision and accuracy of test results, etc., to achieve high accuracy and precision, improve precision and the effects of accuracy, compensating for lack of accuracy and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Reagents and test strips of the present invention

[0040] 1. Reagent composition

[0041] Liquid A is: 133 g of sodium oxalate, 21 g of sodium molybdate (2.1%), the volume of purified water is adjusted to 1000 mL, and the pH value is 3.2.

[0042] Liquid B is: 10 g citric acid (1.0%), 30 mL polypropylene glycol (3.0%), 400 mg phenolphthalein dye (0.04%), and make up to 1000 mL with tetrahydrofuran and toluene (volume ratio 1:1).

[0043] 2. Preparation of test strips

[0044] Dip the filter paper in solution A, absorb the excess solution, and dry it in a drying oven at a drying temperature of 100 °C and a drying time of 30 minutes;

[0045]Dip the dried filter paper soaked in solution A in solution B, absorb excess solution, and dry in a drying oven at a drying temperature of 60°C and a drying time of 30 minutes.

[0046] The dried filter paper is cut into strips, pasted on the PVC sheet, and then cut into suitable strips.

Embodiment 2

[0047] Example 2: Reagents and test strips of the present invention

[0048] 1. Reagent composition

[0049] Liquid A is: 133g sodium oxalate, 12g sucrose (1.2%), purified water to 1000mL, pH value 3.2.

[0050] Liquid B is: 12g citric acid (1.2%), 40mL polypropylene glycol (4.0%), 600mg phenolphthalein dye (0.06%), make up to 1000mL with tetrahydrofuran and toluene (volume ratio 1:1.5).

[0051] 2. Preparation of test strips

[0052] Dip the filter paper in solution A, absorb the excess solution, and dry it in a drying oven at a drying temperature of 100 °C and a drying time of 30 minutes;

[0053] Dip the dried filter paper soaked in solution A in solution B, absorb excess solution, and dry in a drying oven at a drying temperature of 60°C and a drying time of 30 minutes.

[0054] The dried filter paper is cut into strips, pasted on the PVC sheet, and then cut into suitable strips.

Embodiment 3

[0055] Example 3: Reagents and test strips of the present invention

[0056] 1. Reagent composition

[0057] Liquid A is: 133g sodium oxalate, 23g sodium molybdate (2.3%), 13g sucrose (1.3%), purified water to 1000mL, pH 3.2.

[0058] Liquid B is: 13g citric acid (1.3%), 50mL polypropylene glycol (5.0%), 800mg phenolphthalein dye (0.08%), and make up to 1000mL with tetrahydrofuran and toluene (1:1.5 by volume).

[0059] 2. Preparation of test strips

[0060] Dip the filter paper in solution A, absorb the excess solution, and dry it in a drying oven at a drying temperature of 100 °C and a drying time of 30 minutes;

[0061] Dip the dried filter paper soaked in solution A in solution B, absorb excess solution, and dry in a drying oven at a drying temperature of 60°C and a drying time of 30 minutes.

[0062] The dried filter paper is cut into strips, pasted on the PVC sheet, and then cut into suitable strips.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com