Method for producing fermented soybean meal through fat production line

A technology for fermenting soybean meal and production method, applied in the application, animal feed, animal feed and other directions, can solve the problems of small possibility of transformation, large equipment area, large area, etc., to improve quality and reduce land occupation Area, the effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

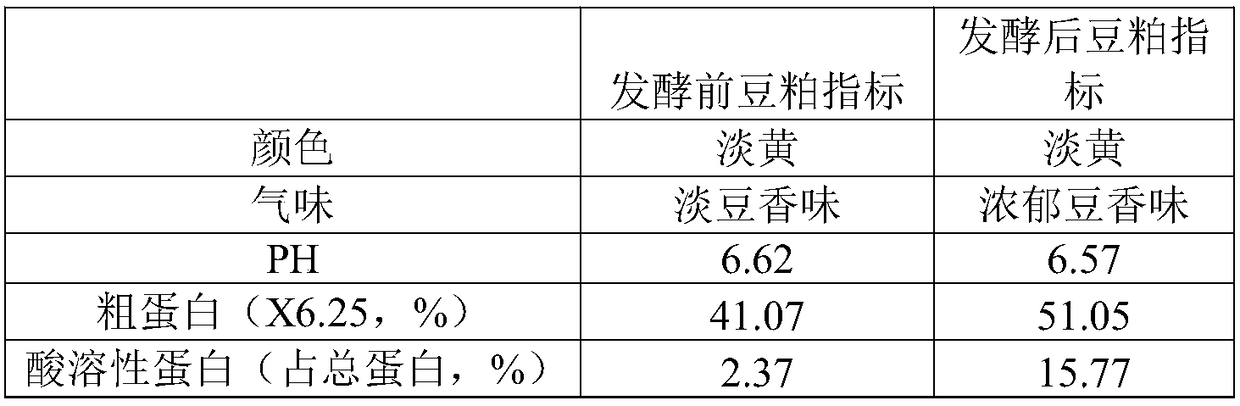

Embodiment 1

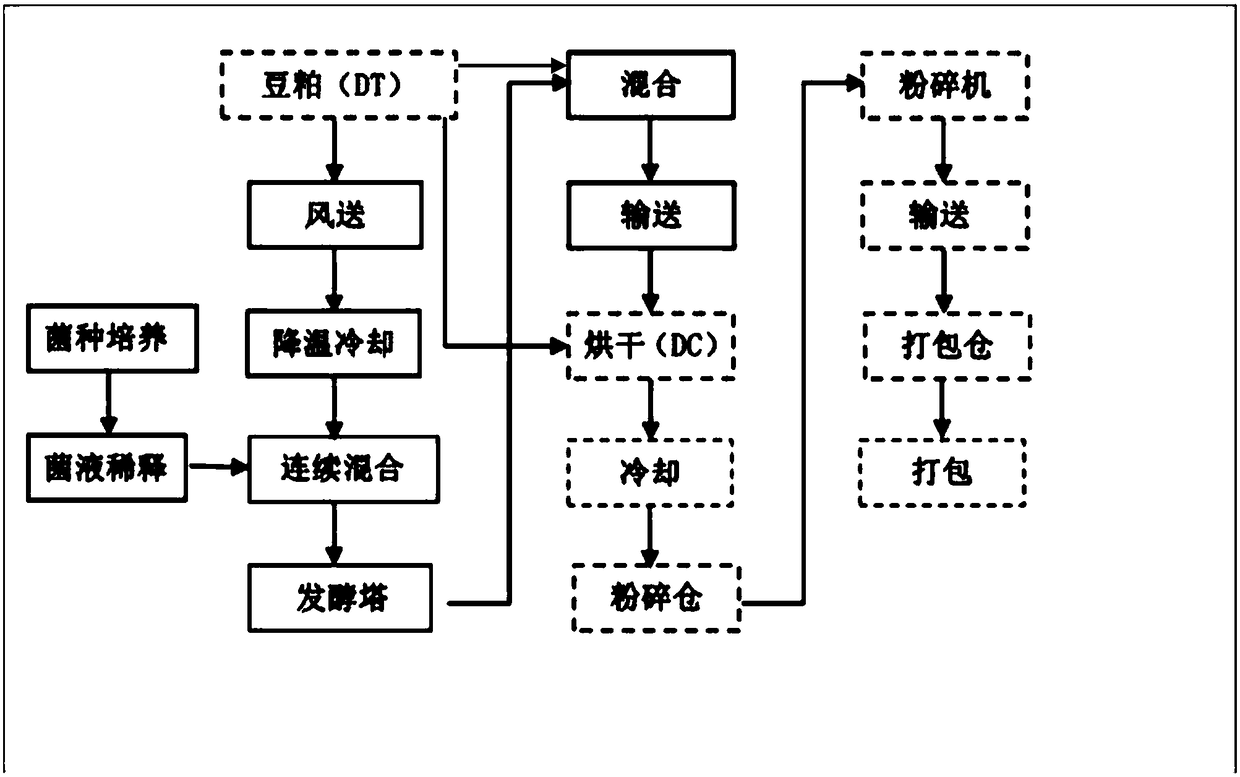

[0045] See figure 1 As shown, a method and application for making full use of the existing production line to produce fermented soybean meal includes the following steps in turn:

[0046] (1) Preparation of composite fermentation broth: add Bacillus coagulans and Saccharomyces cerevisiae in a weight ratio of 2:1 into warm clean water at 40°C, the mass ratio of warm water to bacteria fluid is 30 times, and mix well to form a composite fermentation broth .

[0047] (2) Mixed inoculation: take 5% of DT output as fermented soybean meal, and use a feeder to control the material flow. The temperature of this part of the material can reach 105°C and the humidity is 15%. Roots blower is used to carry out pneumatic conveying to the fermentation tank mixer. During the conveying process, the material is cooled to 40°C, and the material is sent to the mixer through the screw unloader. At the same time, the amount of bacteria liquid and water added is controlled. Soybean meal raw material...

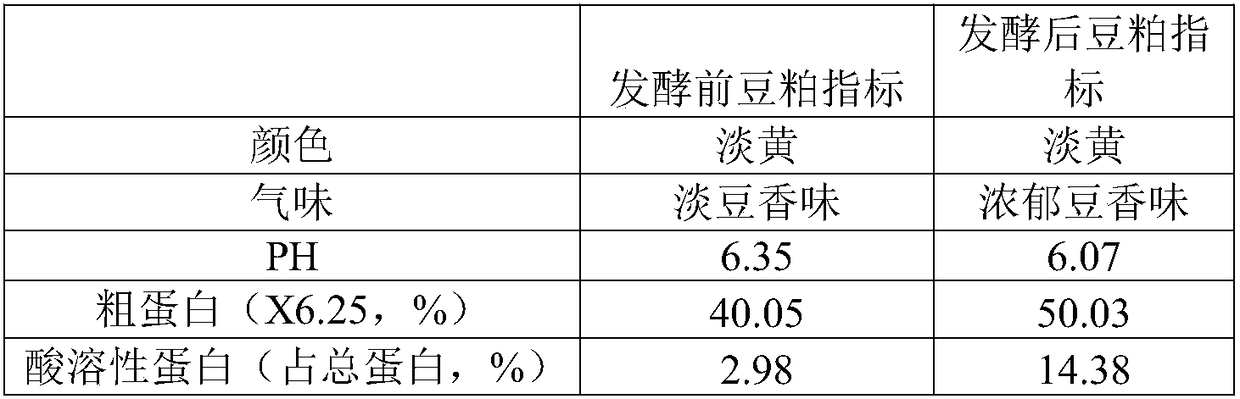

Embodiment 2

[0056] (1) Preparation of composite fermentation broth: add Bacillus coagulans and Saccharomyces cerevisiae in a weight ratio of 2:1 into warm clean water at 40°C, the mass ratio of warm water to bacteria fluid is 30 times, and mix well to form a composite fermentation broth .

[0057] (2) Mixed inoculation: take 10% of DT output as fermented soybean meal, and use a feeder to control the material flow. The temperature of this part of the material can reach 105°C and the humidity is 15%. Roots blower is used to carry out pneumatic conveying to the mixer of the fermenter. During the conveying process, the material is cooled to 42°C, and the material is sent into the mixer through the screw unloader, and the amount of bacterial liquid and water is controlled at the same time. The raw material of soybean meal: clean Water: The mass ratio of the compound fermentation bacteria liquid is 100:50:3, and the water content is guaranteed to be about 40%. It is mixed evenly in the mixer an...

Embodiment 3

[0066] (1) Preparation of composite fermentation broth: add Bacillus coagulans and Saccharomyces cerevisiae in a weight ratio of 2:1 into warm clean water at 40°C, the mass ratio of warm water to bacteria fluid is 30 times, and mix well to form a composite fermentation broth .

[0067] (2) Mixed inoculation: take 10% of DT output as fermented soybean meal, and use a feeder to control the material flow. The temperature of this part of the material can reach 105°C and the humidity is 15%. Roots blower is used to carry out pneumatic conveying to the mixer of the fermenter. During the conveying process, the material is cooled to 42°C, and the material is sent into the mixer through the screw unloader, and the amount of bacterial liquid and water is controlled at the same time. The raw material of soybean meal: clean Water: The mass ratio of the compound fermentation bacteria liquid is 100:50:3, and the water content is guaranteed to be about 40%. It is mixed evenly in the mixer an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com