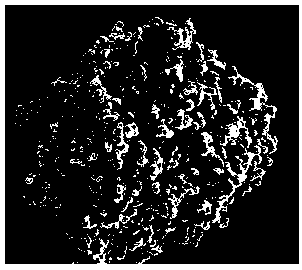

Preparation method of hydrangea-shaped CuZnOX nanometer material and application of hydrangea-shaped CuZnOX nanometer material to electrocatalysis

A nanomaterial, electrocatalysis technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc. Operation control, low cost, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following examples further illustrate the present invention, but are not limited thereto.

[0036] 1. Preparation of Hydrangea-shaped CuZnO X nanomaterials:

[0037] (1) Weigh 2.195g of Zn(CH 3 COO) 2 , dissolved in 50mL of deionized water to obtain 50mL of zinc salt solution.

[0038] (2) Weigh 1.642g of 2-methylimidazole and dissolve in 60mL of deionized water to form 60mL of organic ligand aqueous solution.

[0039] (3) Weigh 1.25g of CuSO 4 • 5H 2 O was dissolved in 10 mL of deionized water to form 10 mL of copper sulfate aqueous solution.

[0040] (4) Quickly add the zinc salt aqueous solution to the organic ligand aqueous solution obtained in step (2), and stir at room temperature for 24 hours to obtain an intermediate product, wash with water and ethanol, and dry naturally to obtain 1.58g zinc metal zeolite imidazole skeleton material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com