Method and application of preparing nitrogen-doped porous carbon material

A nitrogen-doped porous carbon and nitrogen-doped carbon technology, applied in the field of material science, can solve the problems of limitation, high price, complex synthesis process, etc., and achieve the effect of high-value utilization and mild reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

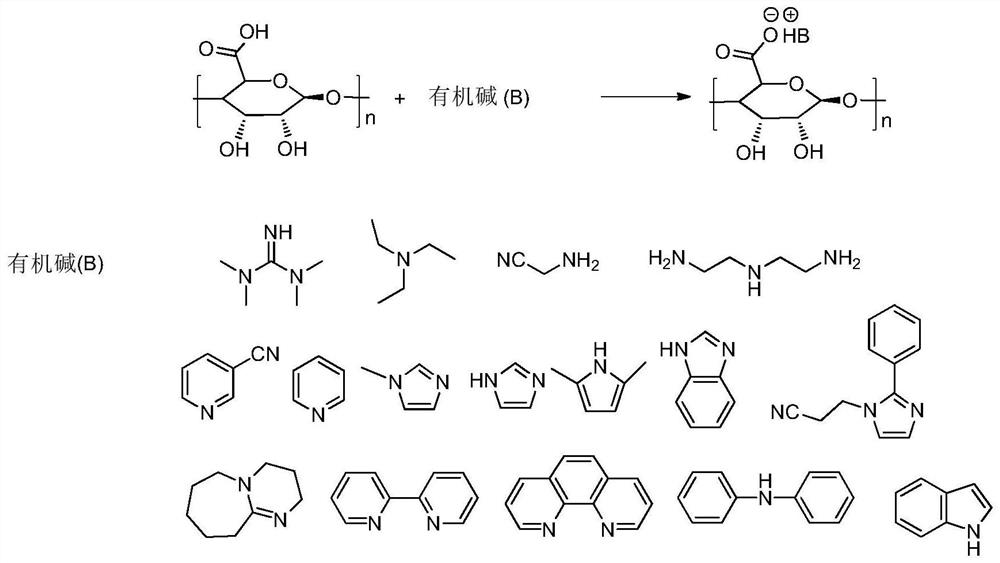

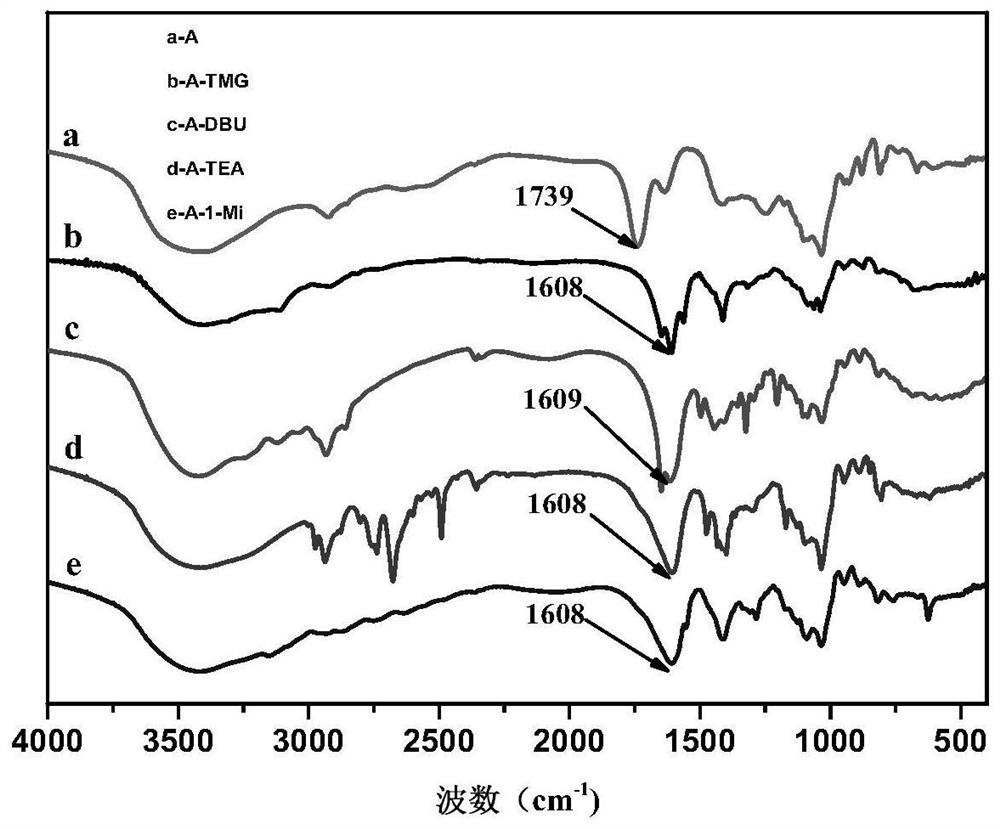

Method used

Image

Examples

Embodiment 1

[0068] Example 1 of the present invention: Preparation of alginic acid-1,8-diazabicycloundec-7-ene protic ionic liquid precursor (A-DBU): Weigh 34.576g DBU and put it into a 250ml flask , add 100ml of pure water, mix completely and add 40g of alginic acid. After reacting at 25°C for 12 hours, the solution was lyophilized for 48 hours. Use a pulverizer to pulverize into powder to prepare A-DBU alginic acid proton type ionic liquid precursor.

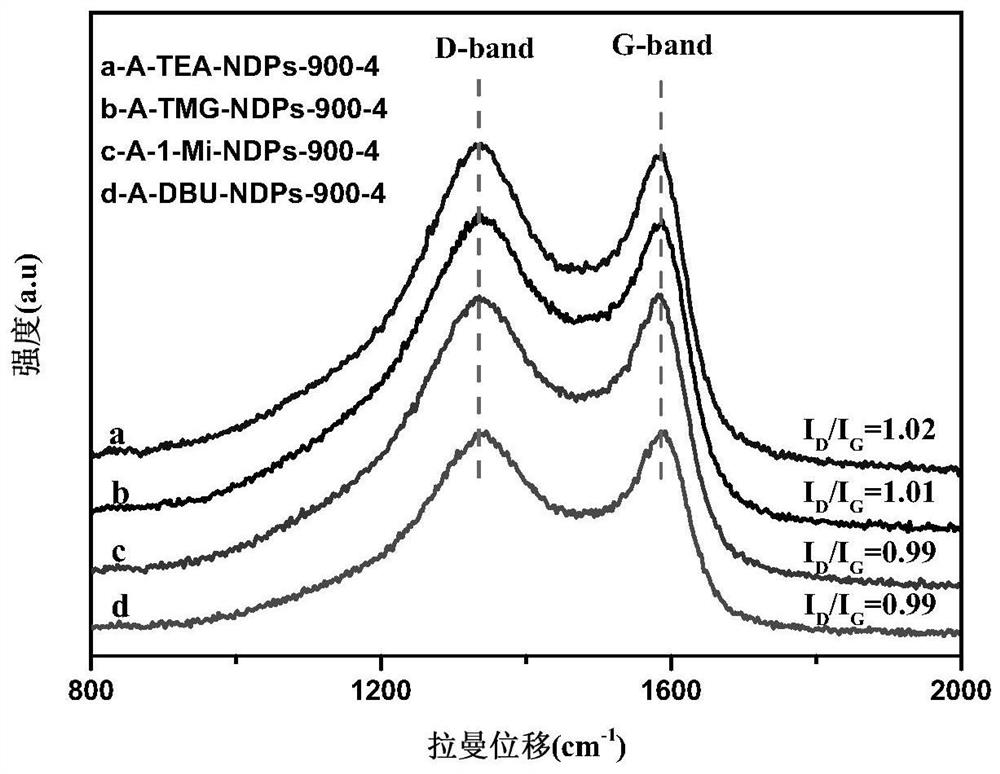

[0069]Preparation of nitrogen-doped porous carbon materials: 10 g of alginic acid-1,8-diazabicycloundec-7-ene proton-type ionic liquid precursor was directly placed in a tube furnace, and the temperature was directly raised under Ar conditions To carbonize at 900°C, the heating rate is 5°C / min, the carbonization time is 2h, and the flow rate of argon gas is 200ml / min. After the temperature dropped to normal temperature, the sample was taken out to obtain the target product-A-DBU-NDPs-900 with a yield of 16.7%, the nitrogen content of th...

Embodiment 2

[0070] Example 2 of the present invention: Preparation of alginic acid-1,8-diazabicycloundec-7-ene protic ionic liquid precursor (A-DBU): Weigh 34.576g DBU and put it into a 250ml flask , add 100ml of pure water, mix completely and add 40g of alginic acid. 40°C, reacted for 8 hours, and dried the solution in a lyophilizer for 48 hours. Use a pulverizer to pulverize into powder to prepare A-DBU alginic acid proton type ionic liquid precursor.

[0071] Preparation of nitrogen-doped porous carbon material: put 10 g of alginic acid-1,8-diazabicycloundec-7-ene proton-type ionic liquid precursor into a tube furnace and carbonize at 500 °C under Ar condition 1h, the heating rate is 5°C / min, the argon gas flow rate is 200ml / min, after the temperature drops to room temperature, weigh 1.75g of the sample, weigh 1.5g of the sample and mix it with 6g of KOH, the ratio is KOH / sample=4 : 1, activate the carbon material at 900°C, and the activation time is 2h. The heating rate is 5°C / mi...

Embodiment 3

[0072] Example 3 of the present invention: Preparation of alginic acid-1,8-diazabicycloundec-7-ene alginic acid proton type ionic liquid precursor (A-DBU): Weigh 34.576g of DBU into 250ml In the flask, add 100ml of pure water, mix completely and add 40g of alginic acid. React at 100°C for 12 hours, and dry the solution in a lyophilizer for 48 hours. Use a pulverizer to pulverize into powder to prepare A-DBU alginic acid proton type ionic liquid precursor.

[0073] Preparation of nitrogen-doped porous carbon materials: 10 g of alginic acid-1,8-diazabicycloundec-7-ene alginic acid proton-type ionic liquid precursor was placed in a tube furnace under the condition of Ar, 500 ℃ carbonization for 1h, the heating rate is 5℃ / min, the argon gas flow rate is 200ml / min, after the temperature drops to room temperature, weigh 1.75g sample, weigh 1.5g sample and 6g KOH to mix and grind, the ratio is KOH / sample =4:1, activate the carbon material at 800°C, and the activation time is 2h. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com