Method for controllably preparing nitrogen-doped porous carbon material, and application

A nitrogen-doped porous carbon and carbonization technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of low specific surface area, small specific capacitance, and inability to control nitrogen doping of carbon materials, and achieve a wide range of effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] We prepared nitrogen-doped porous carbon materials with different structures by using different activation temperatures.

[0075] Take 1 part of cellulose carboxylic acid derivative (CMC) and slowly add it to 80ml of pure water and stir for 2 hours to fully dissolve it to obtain product A; (2) Add 1 part of 1-methylimidazole organic base to product A and stir 12h, freeze-dried to obtain product B; (3) pulverized product B with a pulverizer, and then washed three times with ethyl acetate solvent to obtain product C; (4) vacuum-dried product C at 60°C for 12 hours to obtain proton-type polyionic liquid Precursor product D; (5) Pre-carbonize product D at 500°C for 2 hours in an argon atmosphere tube furnace at a heating rate of 5°C / min and argon flow of 200ml / min to obtain product E; (6) Pre-carbonize product E at 500°C for 2 hours Mix the product with KOH (C / KOH=1:4), place it in an argon atmosphere tube furnace, and activate it at different temperatures (700°C, 800°C, 90...

Embodiment 2

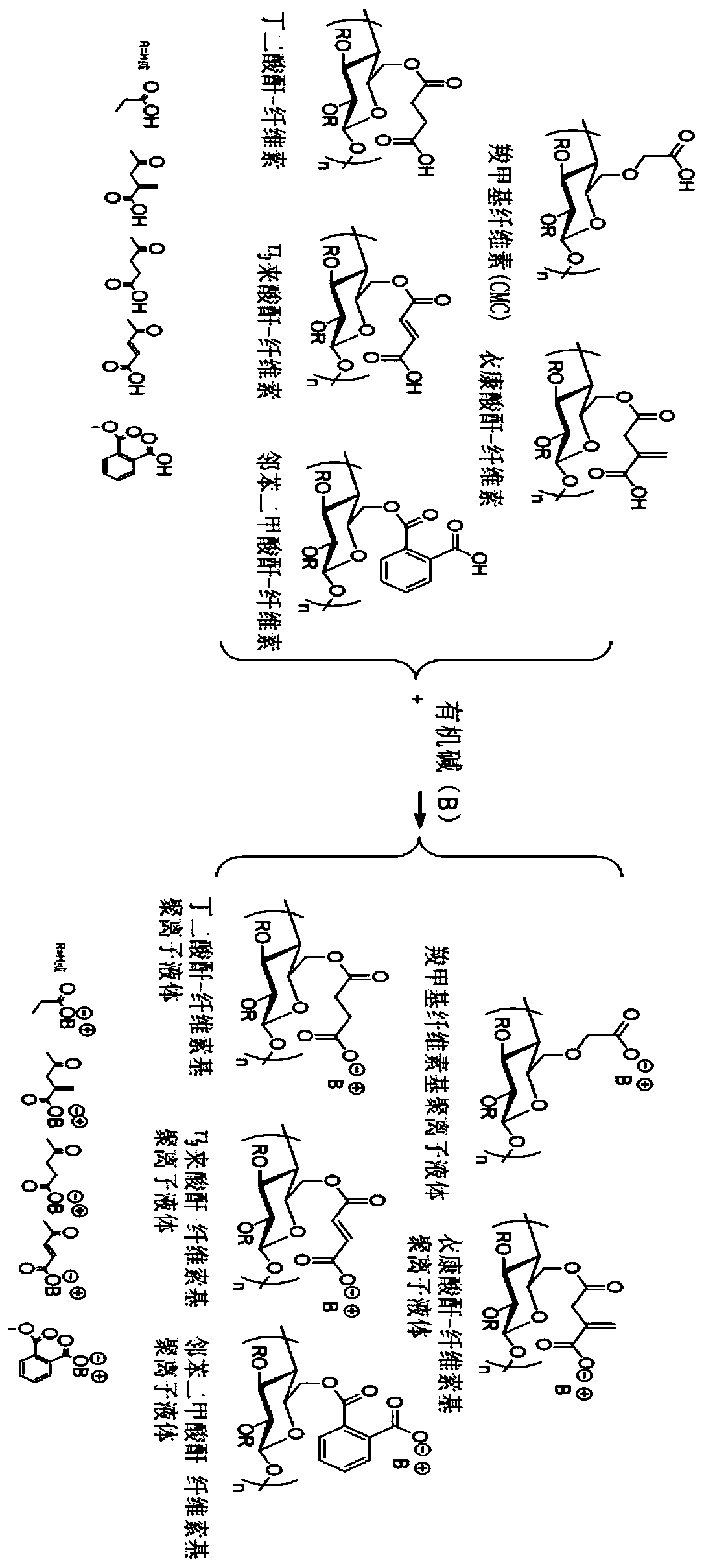

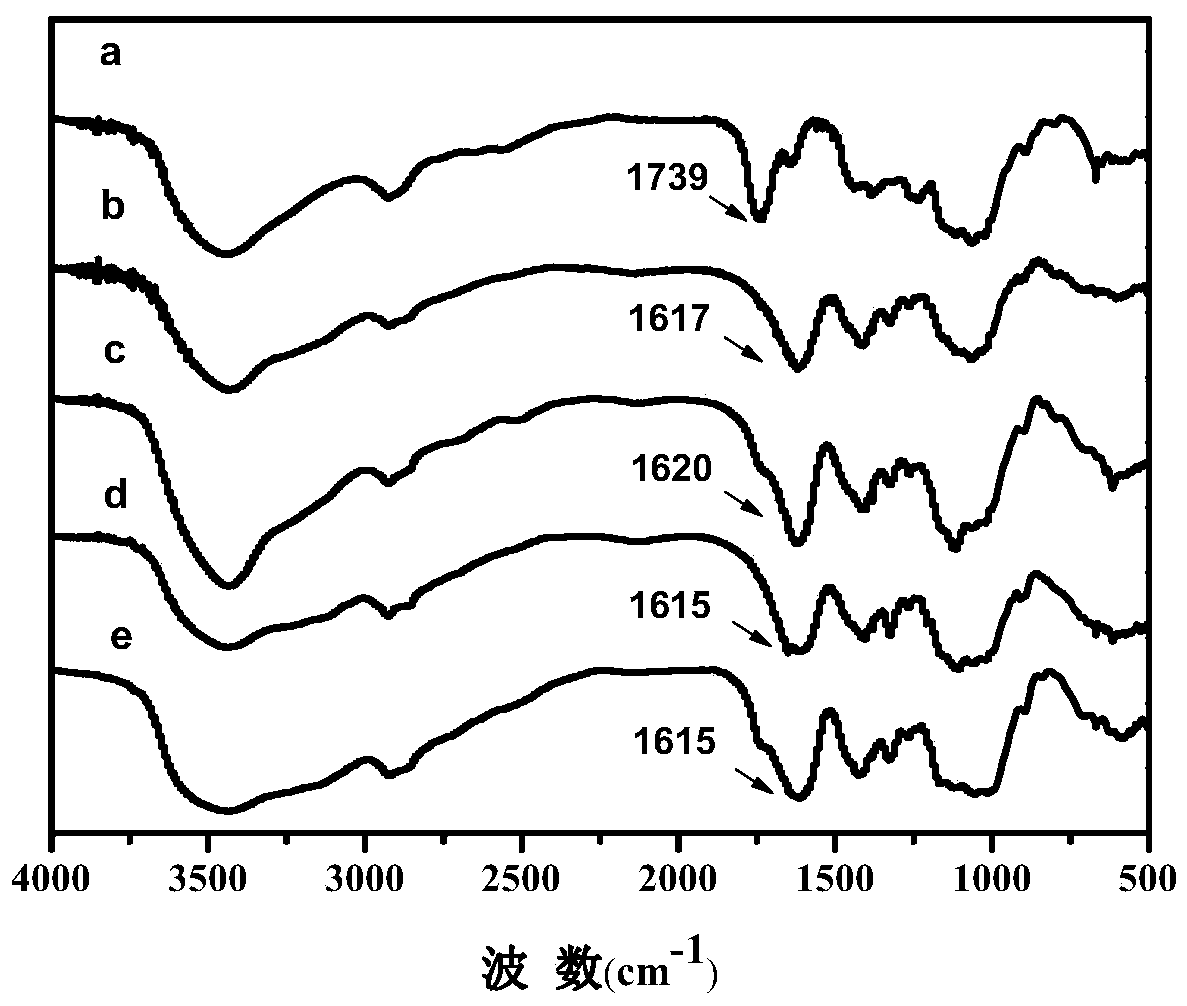

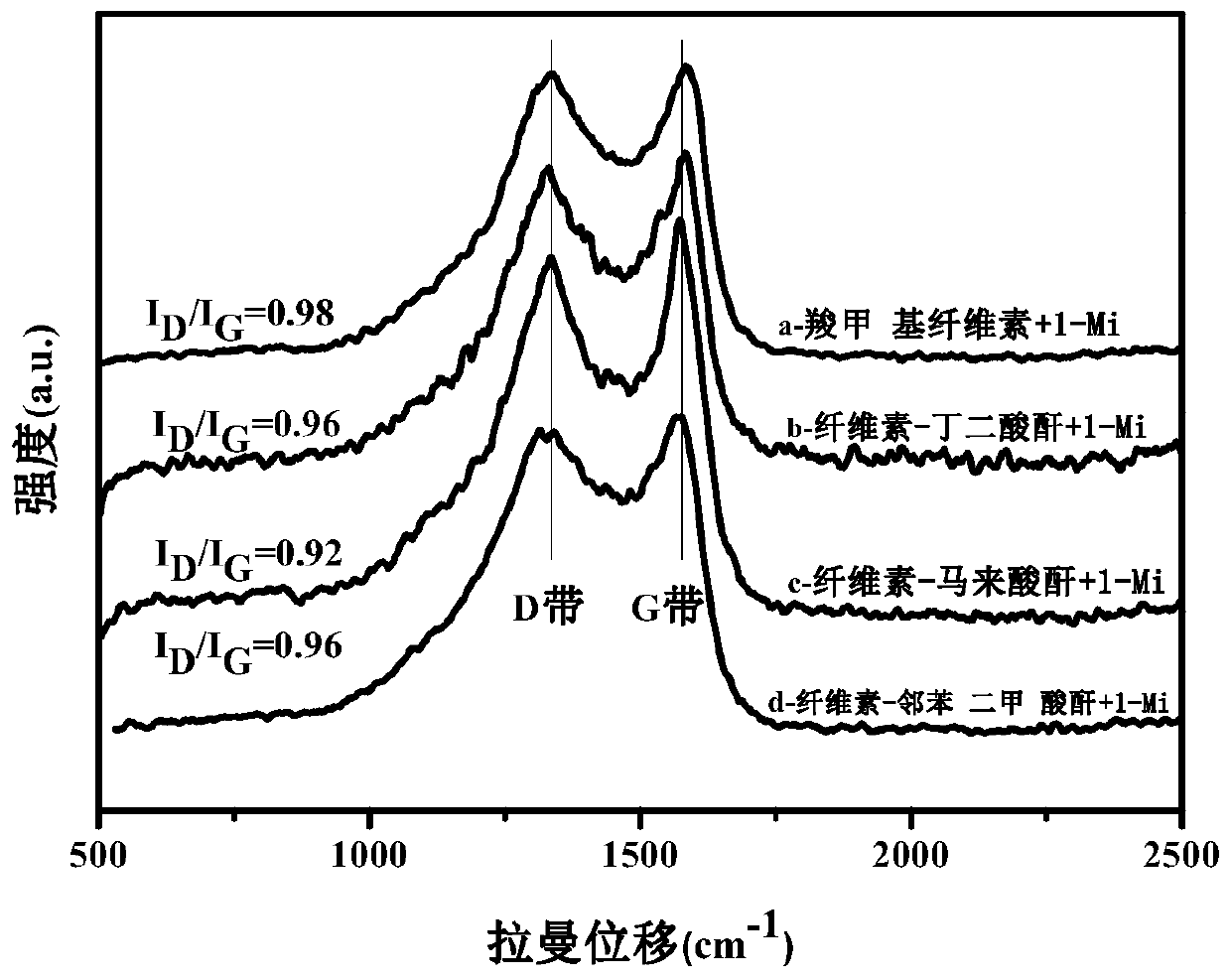

[0079] We prepared nitrogen-doped porous carbon materials with different structures by using polyionic liquid precursors of different cellulose carboxylic acid derivative protonic acids.

[0080] Take 1 part of cellulose carboxylic acid derivatives (carboxymethylcellulose CMC, cellulose-succinic anhydride, cellulose-maleic anhydride, cellulose-phthalic anhydride) and slowly add it to 80ml of pure water and stir for 2h, Make it fully dissolved to obtain product A; (2) add 1 part of 1-methylimidazole to product A and stir for 12 hours, freeze-dry to obtain product B; (3) grind product B with a pulverizer, and then use ethyl acetate The solvent was washed three times to obtain product C; (4) product C was vacuum-dried at 60°C for 12 hours to obtain product D of the proton-type polyionic liquid precursor; (5) product D was placed in an argon atmosphere tube furnace with a heating rate of 5 ℃ / min, the argon gas flow rate is 200ml / min, pre-carbonize at 500℃ for 2h to obtain product ...

Embodiment 3

[0082] We prepared nitrogen-doped porous carbon materials with different structures by using different organic bases.

[0083] Take 1 part of cellulose carboxylic acid derivative and slowly add it into 80ml of pure water and stir for 2 hours to fully dissolve it to obtain product A; (2) add 1 part of organic base (1,8-diazabicyclo [5.4.0] Undec-7-ene, 1-methylimidazole, triethylamine, 1,1,3,3-tetramethylguanidine) and stirred for 12h, freeze-dried to obtain product B; (3) Product B was pulverized with a pulverizer, and then washed three times with ethyl acetate solvent to obtain product C; (4) product C was vacuum-dried at 60°C for 12 hours to obtain product D, a proton-type polyionic liquid precursor; (5) product D was In an argon atmosphere tube furnace, the temperature rise rate is 5°C / min, the flow rate of argon gas is 200ml / min, pre-carbonize at 500°C for 2 hours to obtain product E; (6) fully mix product E with KOH (C / KOH=1: 4), placed in an argon atmosphere tube furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com