Ecological composite coagulant for treating printing and dyeing wastewater, and preparation method and application of coagulant

A technology for printing and dyeing wastewater and coagulant, which is used in water/sewage treatment, chemical instruments and methods, textile industry wastewater treatment, etc. Improve processing efficiency, not easy to break, and the effect of solid particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

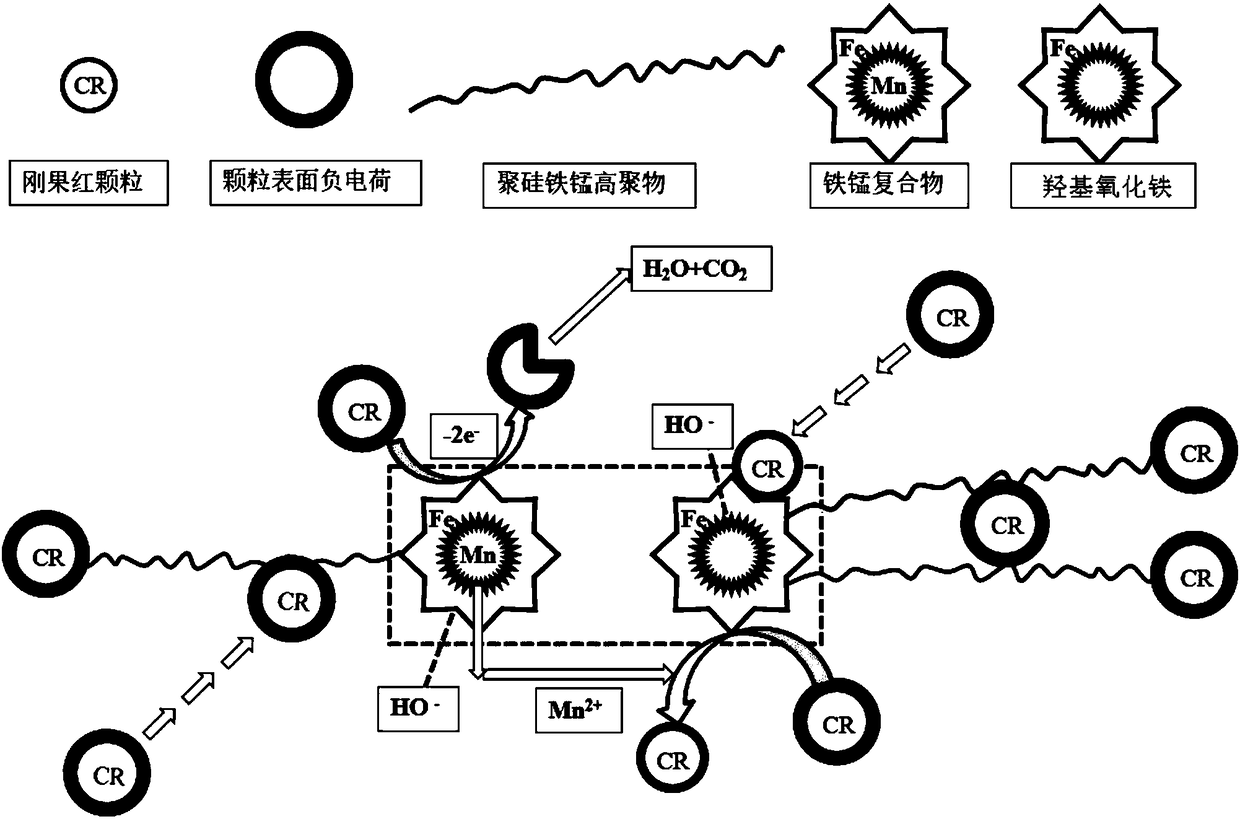

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) The sodium silicate nonahydrate solution that configuration volume is 500mL, concentration is 0.2mol / L, joins in the sulfuric acid solution that 5mL volume fraction is 25% and adjusts the pH value of solution to be 2.5, polymerizes 30min at room temperature, obtains solution, record for solution A.

[0025] (2) Weigh 0.1mol of ferrous sulfate heptahydrate and add it to 50mL of dilute sulfuric acid solution with a volume fraction of 5%, stir until dissolved at a rate of 300r / min, drop into the above solution A, and stir at a rate of 300r / min After 10 min, a mixed solution was obtained, which was designated as solution B.

[0026] (3) Weigh 0.02 mol of potassium permanganate solid and add it to solution B in step (2), stir at 300 r / min until completely dissolved, and age for 12 hours to obtain an ecological composite coagulant.

[0027] (4) Put the ecological composite coagulant in step (3) into the simulated printing and dyeing wastewater, the dosage is 0.2mmol / L, a...

Embodiment 2

[0029] (1) Configure a sodium silicate nonahydrate solution with a volume of 450 mL and a concentration of 0.15 mol / L, add it to 4.5 mL of a sulfuric acid solution with a volume fraction of 25%, adjust the pH value of the solution to 3, and polymerize for 30 minutes at room temperature to obtain a solution, Denoted as solution A.

[0030] (2) Weigh 0.06mol ferrous sulfate heptahydrate and add it to 45mL of dilute sulfuric acid solution with a volume fraction of 5%, stir until dissolved at a rate of 250r / min, drop into the above solution A, and stir at a rate of 250r / min After 20 min, a mixed solution was obtained, which was designated as solution B.

[0031] (3) Weigh 0.015 mol of potassium permanganate solid and add it to solution B in step (2), stir at a rate of 250 r / min until completely dissolved, and age for 24 hours to obtain an ecological composite coagulant.

[0032] (4) Put the ecological composite coagulant in step (3) into the simulated printing and dyeing wastewat...

Embodiment 3

[0034] (1) Configure a sodium silicate nonahydrate solution with a volume of 350 mL and a concentration of 0.1 mol / L, add it to 3.5 mL of a sulfuric acid solution with a volume fraction of 25%, adjust the pH value of the solution to 3.5, and polymerize for 30 minutes at room temperature to obtain a solution, Denoted as solution A.

[0035] (2) Weigh 0.03mol ferrous sulfate heptahydrate and add it to 40mL of dilute sulfuric acid solution with a volume fraction of 5%, stir until dissolved at a rate of 200r / min, drop into the above solution A, and stir at a rate of 200r / min After 30 min, a mixed solution was obtained, which was designated as solution B.

[0036] (3) Weigh 0.01mol potassium permanganate solid and add it to solution B in step (2), stir at a rate of 200r / min until completely dissolved, and age for 36h to obtain an ecological composite coagulant.

[0037] (4) Put the ecological composite coagulant in step (3) into the simulated printing and dyeing wastewater, the do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com