Preparation method for adhesion promoter used for addition type organosilicon packaging adhesive

A technology of adhesion promoter and silicone, which is applied in the field of preparation of adhesion promoters for addition-type silicone packaging adhesives, can solve problems such as environmental pollution, poor compatibility of packaging adhesives, and cumbersome preparation processes, and achieve easy-to-obtain raw materials , good compatibility and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In this example, the preparation method of the adhesion promoter is: add 104.16 g of tetraethyl orthosilicate, 12.5 g of hydroxyl-terminated polysiloxane with a relative molecular mass of 500, and 22.4 g of hexamethyldisiloxane into the In a 500mL three-neck flask equipped with a thermometer, mechanical stirring and condensing reflux tube, stir well at room temperature, add 0.54g hydrochloric acid and 54g deionized water, react at 20°C for 7h, then add 94.53g 3-(2,3-epoxy Propoxy)propyltrimethoxysilane, 24.83g 3-methacryloxypropyltrimethoxysilane and 18.2g hexamethyldisiloxane, react at 90°C for 2h, and finally remove low boilers , to prepare Adhesion Promoter 1.

[0021] The method for preparing the addition-type silicone encapsulant sample is as follows: 100 parts by mass of vinyl methyl silicone resin with a vinyl content of 3.2 wt%, 80 parts by mass of vinyl silicone oil with a viscosity of 5000mPa·s, 11 parts by mass of active hydrogen Hydrogen-containing silicone...

Embodiment 2

[0023] In this example, the preparation method of the adhesion promoter is: add 76.11g of methyl orthosilicate, 10g of hydroxyl-terminated polysiloxane with a relative molecular weight of 1000 and 20.42g of trimethylmethoxysilane into a A 500mL three-necked flask with a thermometer, a mechanical stirrer and a condensing reflux tube, stirred evenly at room temperature, added 0.9g of acetic acid and 18g of deionized water, reacted at 40°C for 3h, then added 55.08g of 3-(2,3-epoxypropylene Oxy)propylmethyldimethoxysilane, 58.08g 3-methacryloxypropylmethyldimethoxysilane and 14.05g trimethylmethoxysilane were reacted at 80°C for 4h, and finally Removal of low boilers yields Adhesion Promoter 2.

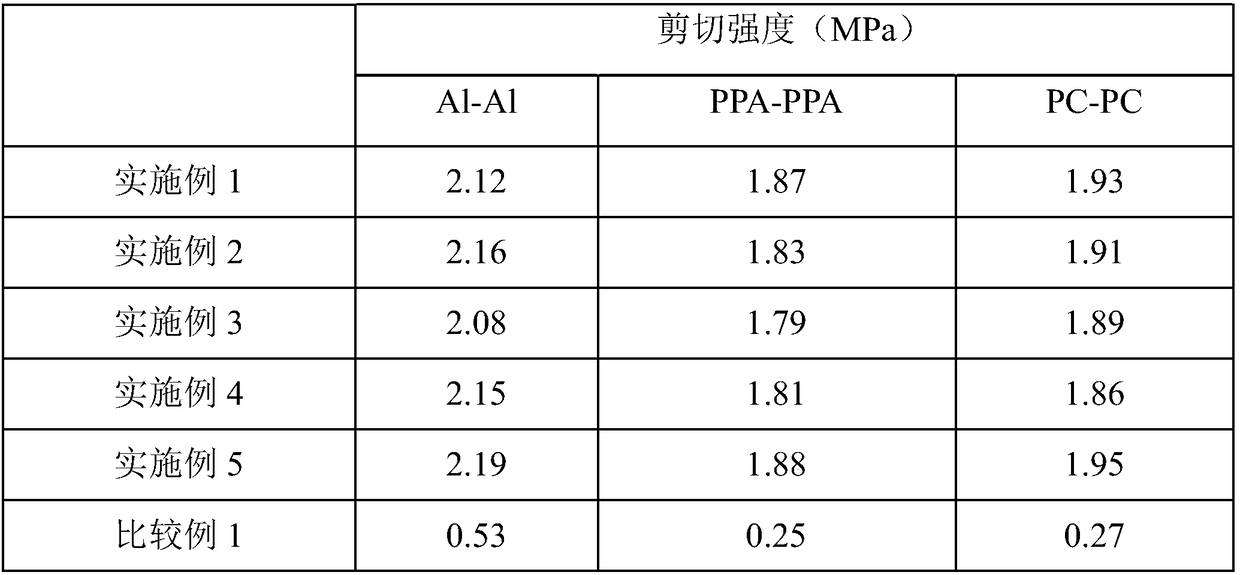

[0024] The method for preparing the addition-type silicone encapsulant sample in this example is basically the same as that in Example 1, except that the adhesion promoter 1 in Example 1 is changed to adhesion promoter 2. The properties of the samples are shown in Table 1 and Table 2.

Embodiment 3

[0026] In this example, the preparation method of the adhesion promoter is: add 89.15g of methyltriethoxysilane, 15g of hydroxyl-terminated polysiloxane with a relative molecular mass of 3000 and 12.32g of trimethylmethoxysilane into the In a 500mL three-neck flask equipped with a thermometer, mechanical stirring and condensing reflux tube, stir well at room temperature, add 0.45g of sulfuric acid and 27g of deionized water, react at 55°C for 2h, then add 41.76g of 3-(2,3-epoxy Propoxy)propyltriethoxysilane, 101.65g 3-methacryloxypropyltriethoxysilane and 11.33g trimethylmethoxysilane were reacted at 70°C for 3h, and finally the low Boiler, obtained adhesion promoter 3.

[0027] The method for preparing the addition-type silicone encapsulating adhesive sample in this example is basically the same as that in Example 1, except that the adhesion promoter 1 in Example 1 is changed to adhesion promoter 3. The properties of the samples are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com